Make a bottle lamp. Do-it-yourself lamps and lamps from plastic and glass bottles

Cutting metal or other hard materials is done with an angle grinder, which is popularly called a grinder. This rather simple tool allows you to cut many materials, with different types of discs. However, holding an angle grinder in your hands does not always achieve a smooth cut.

That is why, there are many different devices, thanks to which it is possible to fix the grinder and make more accurate sawing. But basically these are pendulum-type devices that allow you to cut workpieces across, under a certain degree, both vertically and horizontally.

As for sawing sheet blanks in length, here it is rather necessary to use a technology similar to circular hand saws. There are such devices on sale, although with some skills, this can be done by yourself. It is important to understand the principle of operation of such a device. And if it is necessary for you to do something similar in your work, using the materials that you have or are more available.

There are two options to go here. At the first, it is to fix the grinder under the table, leaving a part of the cutting disk on top through the slot. Perhaps this method is simpler, but if the workpiece does not go smoothly or it is quite heavy, then the cutting disc can wedge and break. Therefore, this option is used for sawing wood with a metal circular saw.

As for sawing sheet or other metal in length, here you need a device that fixes the angle grinder on a sliding frame, such as a well-known circular saw, with the ability to adjust the depth of cut.

As a guide, it can be used as simple rails or metal corners, fastened to the table with clamps, and complex fixtures that have bearings on the carriage that roll along the guide. It is clear that the design will be developed taking into account frequent or one-time use.

It is important, with such a cut, to set up the entire mechanism. It is important that the cutting disc runs parallel to the cut, which is not always possible when installing the grinder on the device. Therefore, you need to pay attention to this, since the disk rotates at high speed, which is not safe, plus if the cut is not even, the cutting width increases.

A carbon grinder (angle grinder) can be one of the most useful and versatile machines if you get the most out of the tool. It is important not to forget how to use an angle grinder. Unlike a drill (rotation 700-1200 min -1), an angle grinder has a rotation speed of up to 12,000 rpm, so it is important to observe some basic precautions.

Features of using the grinder

Protective goggles, hard gloves, safety boots and a dust mask must be worn. Tile jigs are great for cutting directly into the surface of ceramic or stone tiles. However, you will find it difficult if not impossible to make accurate cuts for the workpiece around obstacles. Accessories for old grinder with their own hands easily cope with these complex tasks.

If you cut the bolt flush into concrete or other material. Firmly attach the long side of the rack, making sure it is in place. Part of the workpiece that will fall out after the cut can damage the legs.

With the right choice of disc, your angle grinder can be used to repair rough edges on many household tools, including lawnmower blades, shovels, hoes, and even axles. After that, you can always refine the finish with the windmill file.

It is advisable to use a grinder for work on removing peeling paint, dry cement or rust from metals. There are numerous wire brush rims, all designed for various types stripping, cleaning and deburring. Before making a purchase, check the manufacturer's description.

If you have a lot of grout to remove and the hammer and chisel just won't remove it, a grinder might be the way to go. Using an angle tool to remove the old mortar will result in a lot of dust. Dust mask required.

The technology of work with the device is designed to work with various materials to achieve a variety of finishes and effects. By choosing the right cutting wheel, you can complete an even greater variety of household tasks, including polishing, buffering, sanding, rounding and shaping. Do-it-yourself attachments for a grinder can significantly expand the forms of application.

Materials and fixtures to make nozzles for grinders

Wheels and disks angular grinding machine can be made from a number of materials. However, in the general case diamond disc will provide maximum precision and polish. Wheels are available in a range of abrasion (or grit) levels. Use a higher abrasion accessory for rougher polishing surfaces.

However, despite all this, many people still decide to create components for the Bulgarians with their own hands. If you decide to create fixtures for a working angle grinder yourself, then before starting work you need to prepare the necessary tools:

- An electric drill, preferably.

- Set of drills.

- Discs must be selected with a diameter of 125 mm.

- Wooden blanks.

- Metal corner.

- Steel plate.

- Self-tapping screws.

When it is necessary to use the grinder for specific tasks, in this case, many masters opt for ready-made applications. They can be bought without problems in the construction supermarket. The devices are not very expensive.

Rack for grinder

No matter how skilled the craftsman is, he needs perfect fixtures to get the job done. The angle grinder stand is provided as an excellent tool for perfecting these corner pieces.

The grinder stand allows you to grind at perfect angles of 115 mm-125 mm. If the rack is made of aluminum alloy, this allows you to have a fixture that will undoubtedly last a long time.

Get more out of your angle grinder with this handy holder. Angle grinders are dangerous tools. Homemade grinder tools will allow you to have more control over them, but still we must use all the necessary protective equipment, such as goggles and gloves.

What you need:

- Devices for woodworking.

- Piece of hard plywood 300×100×20 mm.

- A piece of hard plywood 150x100x20mm.

- 1 x M12 screw, 30mm long.

- 2 washers M12.

The design is very simple, it is only necessary to form a part 150X100X20, adapt it to the shape of the grinder.

There is a fixture and simple drawings for a grinder that can be created by hand. The grinder stand is very useful in the metalworking workshop, as well as in woodworking.

Used parts:

- Metal base plate.

- 3 "C- section section angle 2 pcs.

- 1 "L- section section angle 4 pcs.

- Door bracket.

- Rigid spring.

- Nuts and bolts.

- Hardware.

How to do:

- Step 1: Create the stand base. The first step in creating cutting machine with his own hands is his foundation. The whole stand will be made of metal. The base plate and L-shaped metal parts will be used to make the base. The required thickness of the base plate is 3 mm, for better work stand. First of all, you need to cut the L-section into four parts equal to the four sides of the base plate. Then glue the base plate and the L-section together. Make sure the seam is perfect and precise.

- Step 2: C- section to hold the angle grinder. The holding capacity of the C-section channel is very high. A piece of metal is welded to this C-section to hold the angle grinder with a bolt or angle grinder handle.

- Step 3: - Another part of the C-section. Welded metal detail at the end of the C section.

- Step 4: - Attaching both parts of the C-section.

- The door bracket is used to fix both parts of the C-section.

- Step 5: - Attach the springs and the entire assembly. Now this whole assembly is attached to the base with two bolts. Then attach the spring.

- Step 6: - Hold the workpiece.

This is the last step in making an angle grinder. You can use a long bolt and an L-section channel to make a workpiece holder. Two hex bolts are used to attach the L-section channel to the base.

A wall chaser from a grinder allows you to do do-it-yourself tracing for everything Construction Materials in absolute safety, and in the absence of dust. This wall mount is very useful when you need to make cuts for piping, place cables for electrical systems, and install pipes for hydraulic systems.

The saw blade fixed on the shaft is the main element of the device. To ensure safety, the discs are mounted inside a special case, which prevents fragmentation and getting them personally when sawing.

Depending on the properties of the material and density, it is recommended to choose the engine power for a wall chaser from a grinder with your own hands. A modest block is enough for a cable furrow. For a long groove for a pipe, it is advisable to purchase a grinder with a power of at least 2000 watts. Some high-performance models are capable of reaching speeds of around 6200 rpm, which guarantees the ability to cope with industrial scale.

But the design of the grinder is such that it cannot be used due to the active formation of dust. Often they resort to upgrading the device.

You can design a device with two discs. Installing a machine from a suitable grinder with your own hands of this type will cost more. The first drive is attached as usual and the second one is mounted. A second nut is needed, which has an additional ring, for fixing. When working on the wall, the sander must be in the protective cover.

Frazier

Since any angle grinder is equipped with a powerful motor with a gearbox, it can be made into stationary router. Provided that the machines from the grinder with their own hands at any time can remove the device for use for its intended purpose. The shaft of the grinder is brought out into the hole of the workbench, a cartridge for milling heads is put on it - and not too hard woods can be processed.

- Step 1: Create the angle grinder bracket. You can use the threaded holes in the grinders as reference points for the bracket. There are many ways to approach making a handle, depending on the type of grinder you choose to work with. Critical measurements needed for layout functional design, which makes it easy to separate the grinder for manual work. It took five pieces of a flat metal rod to assemble the device. Welding them together created a custom bracket. It is necessary to weld a short armature as a rod to attach a wooden handle.

- Step 2: Create a clamp that will firmly hold the handle of the grinding head against the head of the adjusting bolt.

- Step 3: You then need to attach a leg to the front end of the rods to secure the angle grinder bracket by turning on the hinge function to allow the grinder to pivot towards the cutting table.

- Stage 4: Building the foundation. It is possible to use a simple frame by using tubes and mounting them with two pieces of iron. It is necessary to form a flat platform for mounting the slider mechanism.

- Stage 5: Assembly.

- Step 6: Adding a cutting table. The cutting table consists of a steel plate. After all parts are assembled and adjusted, level the vertical surface of the cutting wheel.

- Stage 7: Final testing.

Clamp for grinder

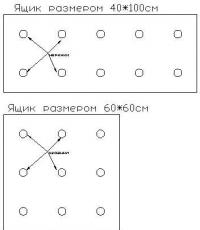

Create a wooden box. You will need a base for this model. You can use wood and use liquid nails. But you can use plastic, metal or wooden box.

Check if the angle grinder is suitable

Make sure the grinder's fuse doesn't trip when you attach the grinder and make sure the fuse is flush with the box. Attach the grinder and check the work.

Miter box from grinder

The miter box from the grinder makes working with the device much easier.

Material:

- iron plate 1×200×100×2 mm;

- iron rod 2×150×30×3 mm;

- iron rod 2×40×30×3 mm;

- iron rod 2×30×30×3 mm;

- 1×8×80mm screws;

- 2x8mm nuts;

- 2x8mm washers;

- screws 2 × 7 × 30 mm;

- screws 1×7×50 mm;

- 3x7mm nuts;

How to do:

- Step 1: Create the stand base.

- Step 2: Material preparation

- Adjust the dimensions of the metal plate 200×100×2 mm so that the sides are at right angles (90°);

- It is necessary to cut 2 blanks of an iron beam 40 × 30 × 3 mm;

- Mark the center and drill a 10mm hole on one side. The hole should have a diameter of 7 mm;

- Cut two pieces of iron 150 mm;

- These blanks require 3 holes. The hole must be located 10 mm from the edge;

- The holes must match the bolts;

- Shaping the rods is necessary in accordance with the grinder to match the profile of the machine;

- Cut off one piece of 30mm iron rod. Drill a hole with a diameter of 7 mm.

- Step 3: Launching the Bracket

- Then screw these parts into the machine and adjust them. One will be fixed in the right side hole and the other will be fixed in the top hole;

- Then give a soldering point;

- Then weld another 30mm piece already drilled. For easier alignment, use a 7mm screw to secure them. Then it is necessary to weld (give only one connection point) a piece of iron rod 30 mm from the side.

At this stage, it is important that the final part is at a right angle.

- Step 4: Base

- Take 2 pieces of 40x30x3mm iron bar and place them on the sides on both sides and change the screw to connect them and make soldering easier.

- Position the attached set of brackets and sides on the plate so that it is more offset to the right. There should be a slight difference on both sides.

- Then it is required to weld the fixture elements (give only one soldering point) on both sides. Make the necessary adjustments. There should be no excessive displacements.

- To facilitate movement, two washers are intelligently installed between the side and the handles.

- Step 5: Completing the Assembly

- Watch to see if you are moving freely, and the angle can reach -90º.

- After checking alignment, perform final welding.

- Step 6: Processing the base. Mark the cut. Start by gluing the corners and finishing with a saw.

- Step 7: Base with sander installed. Take advantage of the handle support that already accompanies the equipment and replace the original screw.

- Step 8: Screw Depth Hole. The screw allows you to adjust the depth of the cut. Pay attention to the alignment of the disc in the longitudinal and transverse directions.

- Step 9: Reminder. Remember that this instruction is for a grinder with three factory holes. This made it possible to fix the machine in the support, and the third hole regulates the cutting depth during operation.

Sawing device for porcelain stoneware

By tilting the fixture, expensive material can be easily inspected. It is advisable to use special machines to accurately adjust the movement of the fixture. It is possible to make the necessary mechanism from an old grinder.

Such a technique requires the installation of several guides on the platform, followed by movement along the intended trajectory. Also, a homemade fixture will allow you to change the angle of cut and the depth of processing. To create a machine for porcelain stoneware, you will need proven drawings and work experience.

How to make a frame for a grinder

The grinder can be used for grinding or cutting when changing the necessary nozzles, according to the principle of operation of a circular saw. Thus, it is possible to process pipes and workpieces even with a large diameter along an even cross-sectional angle.

To create a bed, you need:

- Bulgarian.

- Drill.

- Welding fixture.

- Steel plate.

- Steel plate 3 mm thick.

- 40×40×5 mm square tube.

- L-profile 30×30×3.

- 80mm screw, nut, two screws, spring washers.

- Step 1. You need to cut off the details right size and clean the ribs from chips and irregularities.

- Step 2: Easy mount for angle grinder.

Next, you need to create handles on both sides for the grinder, which will increase the number of possible positions during operation.

The grinder handles can be angled slightly instead of pointing straight up and down for a comfortable grip. The clamp that connects the handles to the grinder can be V-shaped, which will create optimal conditions for a great job. This shape makes this simple structure strong enough that no additional connections are needed. To connect the new module, factory threaded grooves from the grinder are used. Before welding, simply install these plates and screw (to disassemble the joint if necessary) using an angle grinder. Keep the cutting disc in place and use a right angle for the lining. - Step 3: Make an additional position for the handles.

A hole has been made, large enough for the handle threads to fit securely into the slots (10mm). Cut off the handle needed for the shape base and fasten the nut to the drilled hole.

Next, you need to weld the elements. Place and shape it so that you can still press the Disk Lock button. This way you can change the new drive without having to uninstall your application. - Step 4: Create the bottom plate.

It is necessary to create 8mm holes for the “rear stop”, this is the part of the 30x15mm L-profile mentioned earlier. Connected to it by butt welds. This way the bottom plate stays straight and the result looks better.

- Step 5: Connecting to the bottom.

Connect these two parts of the metal module together.

You can use a simple "hinge" from a piece of 40x40x5mm square tubing.

Drilled hole 12 mm diameter to the center of the side, through both surfaces. The product is welded. - Step 6. The material is pushed off the "hindfoot" so that the angle grinder is suitable for moving lower vertically. Welds need to be cleaned with a steel brush and finally painted in the desired color.

Tripod for angle grinder

The personal angle grinder attachment turns the angle grinder into a versatile and precise cutting attachment for steel, metals, profiles, pipes and rods. This block has versatile applications and is suitable for most common angle grinders. The latch for the grinder received various forms of execution. It is necessary to create universal adjustable mounting brackets for an angle grinder. Provide protection against metal sparks.

Protractor for grinder

When working with a metal profile or important details requiring even seams, it is effective to use a protractor for a grinder. Using the device allows even an inexperienced person to create a cut exactly with a given slope. The protractor is irreplaceable during the work with a ceramic tile and a plinth. If desired, they often create a homemade protractor for homework with a grinder.

To begin with, the guide corner is installed, equipped with a special pad on a flat surface ( ceramic tile). This is done to secure the workpiece and prevent displacement. The workpiece is pressed tightly, after which the required angle of inclination is adjusted.

After that, the master proceeds to sawing the workpiece, slightly pressing on the disk.

In the design of a do-it-yourself protractor, three main components can be distinguished:

- corners.

- Loops.

- Pain to fix.

The principle of operation of the protractor is to install a special guide corner with an overlay on the processing workpiece. Creating an accurate protractor is a rather laborious process.

Bench grinder for grinder

Required fixtures and materials:

- grinding device with an abrasive disc;

- racks (16 mm);

- a small piece of scrap (square or rectangle from 12 to 25 mm);

- plywood (6.5 mm);

- hand saw;

- drill with sorted drills;

- reciprocating saw or coping saw;

- optional but highly recommended.

- Step 1: Design. This model is designed for a cheap grinder. Think through all the details.

- Step 2. Getting started. You will need a base and some support to get your grinder high enough to clear the wheel. Processing can be done with a hand saw.

- Step 3: Support. Mark and cut out the 2 side supports, then forward and secure them with screws, pre-drill them (dimensions may vary).

- Step 4: Drill and fasten. Next, you need a bolt that fits into the hole for the handle of your angle grinder.

- Step 5: Fixture Restoration. Now you need 2 sides. Where the scrapers will make the circuit stronger, but if you don't have a fixture, it will work without them.

- Step 6 A tongue is a depression or groove in the edge of a piece of work material for attaching another board. There are several ways to add them. The easiest of them will be with a table saw, but if it is not available, another way is possible. Method 1. Mark where you want to get the tongue, pinch a piece and use a saw to cut gently on the side of the line. If you want to make it easier, you can take a piece of wood and place it on the side of your line to make a barrier. You can keep making cuts along the side until you reach the end, and then cut out what's left of the excess material.

- Step 7: Method 2 This method is much faster and more accurate if you have a router, you can make a small table for it.

- Step 8: Combine the elements. Now mount your 2 sides and measure the dimensions of the top of the product, cut out the required cover and install.

- Step 9: Strap. One bolt is not enough to hold an angle grinder. The bolt is subjected to flow on it, so find some strapping material, duct tape. Such products will work if you have absolutely nothing. You can use a small strip of metal.

corner Sander gained popularity due to its versatility. This type the tool is universal, as it is capable of performing such work as cutting, grinding, cleaning. Functional this instrument can be expanded, but this will require some adaptations. These are devices for grinders that will make it possible to make a milling machine, wall chaser, cutting machine and others out of the tool.

To make any device for a grinder with your own hands, first you need to decide what materials for manufacturing are available. You should also decide what exactly should be made: a milling or cutting machine, a wall chaser or a dust collector for working with tools indoors.

For the manufacture of such devices, there is usually no need to buy additional materials or parts, since absolutely any simple materials at hand will do. For the manufacture of some devices, such as a dust collector casing, it is enough to use a plastic canister from under the oil or brake fluid. Using a tin can, you can design a hand mill for making wholemeal flour.

It is important to know! Getting started, decide what exactly you want to get from the grinder in the end. After all, such a design should be necessary, and of course reliable.

Rack for grinder

Such a device for a grinder, like a stand, will not be made by hand special work. Its manufacture will allow you to use the tool to perform more accurate sawing work. various kinds materials. In the manufacture of a cutting machine, the following tasks must be performed:

- Reliability of fixing the tool.

- Reliable fixation of the tool in the upper position.

- Ensuring minimal deviations from the plane of the cut.

Threaded connections are well suited for reliable fastening of the angle grinder. Additionally, you should also worry about safety, so the tool should be equipped with a homemade casing.

For grinders for circles with a diameter of 115 mm to 150 mm, it is possible to attach them to the rack with clamps. Tools for a circle diameter over 150 mm must be securely fastened not only to the moving console, but also to the desktop or bed. To reduce vibrations and increase cutting accuracy, it is recommended to fix the bed rigidly on a workbench or other base. Below is another version of the rack with a fixed grinder.

Do-it-yourself pendulum cutting machine

For the manufacture of such a device from a grinder as a pendulum cutting machine, it will be necessary to ensure the automatic return of the moving console to the opposite position. This is achieved by installing a special spring, rubber band or counterweight, which will automatically return the used angle grinder to its original position.

The production technology of such a machine is almost identical to the previous one. The difference lies in the addition of an auto-return mechanism of the movable part, on which the grinder is fixed. Thus, the work of a person is facilitated.

Milling cutter from grinder

The grinder can also be used as a milling cutter. It is important to take into account the fact that the tool must be able to extract from homemade device. To make such a design, you will need to fix the angle grinder under the table (or workbench), and bring the tool shaft into the workbench hole using an adapter with a collet clamp for cutters. The made tool can carry out various woodworking, depending on the cutter used.

Bulgarian circular

You can make a grinder from a grinder. To do this, you need to make a reliable frame or base, to which the tool will be attached.

It is important to know! Woodworking discs must only be used in good quality. The absence of at least one tooth prohibits the use of a disc for cutting wood.

If in the manufacture of a cutting machine cutting tool should be above the desktop, then when designing the milling unit and circular, the opposite is true. The grinder should be placed under the tabletop, from which a certain part of the disk comes out through the corresponding hole. In addition to the countertop, you can screw a ruler with which more accurate sawing of wood will be carried out.

Do-it-yourself wall chaser from a grinder

The grinder can be used to cut holes in the wall. They are made in order to be able to lay wiring, pipes and other elements in them. When working with a stock grinder, it is very difficult to control the depth of immersion of the disc. To solve this problem, you can make a special frame.

It is important to know! Such a device for a grinder has an important advantage, as it allows you to adjust the depth of the strobe being performed.

Such a frame is a sole with an emphasis, through which it is possible to move the tool along the wall with uniform depth, thereby obtaining a strobe of the required depth. In the manufacture of this, pay attention to the protective cover and a special dust collector. You can use a bag as a dust collector, but it is more convenient to connect a hose from a vacuum cleaner. With it, dust will be sucked out, making such work much more pleasant and dust-free.

About homemade dust collector

A dust collector or casing for an angle grinder can be made from an old aluminum pan, pieces of thin metal or plastic canister. From the pan, the casing will be more reliable, but at the same time, the plastic construction is much easier to manufacture.

For construction, a galvanized sheet is also suitable, which should be welded based on the dimensions of the available tool. An important condition is the reliability of fixing such a homemade product on the angle grinder. In addition, the dust collection hole can be made with the most convenient angle of inclination, unlike purchased dust collectors.

Protractor for grinder

A protractor for a grinder is also called a device for cutting along guides. For the manufacture of such a device, a metal profile or channel is most often taken. To construct a protractor, it is required to build a structure from the corners of the metal, as shown in the photo below.

Now it remains only to fix the tool to the resulting product, resulting in a full-fledged protractor, through which you can adjust the cutting depth.

In conclusion, it should be noted that the material presents only the main types of devices. In fact, the angle grinder is such a versatile unit that ideas for its modernization are constantly being updated. Choose from the proposed list of necessary devices for you and translate them into reality.

Without an angle grinder - a grinder - you can not do it either in the garage or in a private courtyard. The unit allows you to cut a metal profile, clean weld or remove rust from the surface of workpieces and parts, has a low price and incredible ease of use. The grinder also has disadvantages, one of which is the unstable quality of the cut and the danger of the cutting disc being skewed during use. You can eliminate annoying shortcomings by making a special frame with your own hands, which will turn a hand tool into a real cutting machine. This will increase the speed of work and achieve accuracy that can only be obtained on industrial equipment.

Scope of cutting machines

Cutting disc machines are widely used in metalworking, mechanical engineering, woodworking and furniture industries. The units have found their application in household: they are used as a handy tool to carry out various works workshop and garage. The cutting machine is convenient to use for solving a number of tasks:

The advantages of disc cutting machines include convenience and ease of use, high speed and cutting accuracy, the ability to replace the cutting disc in a matter of minutes.

Due to the relatively low cost, universal units have a fast self-sufficiency, so it is beneficial to use them in small industries and small workshops.

In the household, a cutting machine is used irregularly, so buying a factory-made tool is irrational. It is better to make a special bed for an angle grinder. This will increase the versatility of the grinder, turning it into a small-sized cutting machine.

Types of devices, their advantages and disadvantages

There are two types of designs of cutting machines, differing in the location of the grinder, which can be made at home.

The first installation is a bed with an angle grinder rigidly fixed under it. On the working surface, only the cutting disc is visible, which freely passes into the slot of the table. cutting metal profile or sheet in this case is completely identical to sawing wooden blanks with a circular saw. Despite the very simple design, such a scheme is not particularly popular. Those who made such a device note the inconvenience in use due to the need to move the workpiece. This significantly reduces the accuracy of the work and makes the process unsafe. The only advantage of a machine with a bottom angle grinder is the ability to quickly cut thin metal sheets.

A cutting machine with a lower angle grinder can be used both for cutting metal and as a circular saw

The second scheme, in which the part remains stationary, and the cutting wheel itself moves, is more convenient. The so-called pendulum saw, placed above the tabletop, allows you to cut the workpiece exactly at the required angle, while it becomes possible to make the right number of parts of the same type. Due to the location of the grinder on top, cutting workpieces does not require effort, and the operation of the unit becomes simple and safe. The undoubted advantages of the design include the ability to quickly dismantle the angle grinder for traditional use. As for the disadvantages of this method, the weak link can be considered a swivel, which complicates the design of the machine.

The machine for cutting metal with the top location of the grinder has a more convenient design and makes it possible to cut blanks at the desired angle

The device of a pendulum saw from a grinder

A pendulum saw from a grinder is available for assembly at home, does not require expensive materials and special skills. The cutting machine has a simple design and consists of several components:

- bed;

- pendulum;

- fastening under the angle grinder.

The bed is a steel frame welded from shaped pipes, with a platform made of sheet metal not less than 3 mm thick. A bracket is attached to this plate, on which the hinge of the pendulum saw is mounted, as well as an emphasis to hold the workpiece. By the way, there can be several such stops: it is convenient when one element allows you to make perpendicular cut, and the other makes it possible to cut the material under required angle. The most perfect stop is a rotary device with a protractor, with the help of which any angle between the part and the cutting disc is set. An important detail: at the point where the saw touches the platform, a cut is made in the tabletop, its width should be equal to twice the thickness of the cutting circle, and the length should correspond to the diameter.

The standard design consists of a bed, a pendulum and a mount for an angle grinder

The pendulum of the cutting machine is a T-shaped piece made of a rectangular metal profile. On the one hand, this assembly is attached by a movable joint to the frame bracket, and on the other hand, a mount for a grinder is attached to it. The mobility of the hinge of the pendulum saw is provided by rolling bearings or bushings, and the return of the tool to its original position is provided by a flexible element (rubber band or spring).

The grinder mount is a console with one or two brackets connected to the pendulum. An angle grinder is attached to one of them with bolts. To do this, threaded holes are provided in the body of its gearbox for attaching the handle. The second bracket is a conventional clamp (ladder) that holds the cutting tool by the body.

Convenience in the operation of equipment can be significantly increased by connecting the angle grinder to a foot switch-pedal. Of course, in this case, the angle grinder start lever is brought into working position and fixed with a special button.

Necessary tools and materials

When starting to manufacture a cutting machine, it should be understood that the accuracy of its work is directly related to the stability of the structure. Therefore, the choice of a material of a certain thickness is dictated not so much by the requirements for the strength of the hull, but by the need for its rigidity.

Before starting work, you need to prepare:

- profile pipe "square" (25x25x2.5 mm);

- profile pipe "rectangle" (40x20x2.5 mm);

- metal sheet 4–5 mm thick;

- ball bearings No. 202, 203 or 204 - 2 pcs.;

- a calibrated bar with a thickness equal to the diameter of the hole in the inner race of the bearing (up to 100 mm);

- bar with a diameter of 8–10 mm;

- metal tire (20x4 mm);

- bolts and nuts with M8 or M thread.

Of the tools you will need:

- Angle Grinder;

- drill or drilling machine, set of drills;

- a set of dies for cutting metric threads;

- wrenches;

- welding machine.

The presence of electric welding is desirable, but not necessary - all connections can be made on threaded connections. However, it should be understood that this method reduces the reliability and strength of the structure.

For the manufacture of the machine, it is better to choose a grinder from a well-known manufacturer

The main unit of the cutting machine is the angle grinder. It is not recommended to use a "small" grinder, designed for cutting discs with a diameter of up to 125 mm with a power of up to 500-600 watts. Remember that the larger the diameter of the cutting wheel, the more versatile and reliable the machine will be.

The careful choice of power tools is also due to the wide variety of designs of angle grinders on the market. Since such equipment is not unified, the cutting machine is built for a specific model and size of the angle grinder. If the equipment is unreliable, then in case of failure it will be difficult to install another angle grinder in its place without the need to remake the mounts and the pendulum. That is why it is better to choose products from trusted manufacturers - Makita, Bosch and so on.

Making a cutting machine with your own hands

Preparatory stage

Work on a cutting machine begins with design. It is impossible to give the exact dimensions of the device, since the design depends on the model and size of the particular angle grinder. Nevertheless, according to the presented drawings, you can get an idea of the dimensions and structure of the equipment.

A project sketch begins with a hull drawing. You may not need a frame, but a separate platform that can be attached to locksmith's workbench. In any case, the dimensions of the device and the location on the body of the main components are determined. Next, the angle grinder and the center distances of the mounting holes on the body of its gearbox are measured. Based on these indicators, a drawing is drawn up for attaching the grinder to the pendulum. After that, the rotary assembly itself is designed. The smaller the distance from the swivel to the cutting wheel, the stiffer and more accurate the machine will be. In other words, the length of the pendulum should be as short as possible.

On the last step designing calculate how much and what kind of material will be needed.

Photo gallery: Drawings for the manufacture of a homemade cutting machine

Drawing of a frame-type cutting machine. Frame dimensions are selected based on the dimensions of the tool used.

Drawing cutting machine pendulum type. On the left are the dimensions of the base. The design features of the pendulum are marked on the right.

Step-by-step instruction

- In accordance with the drawing, the blanks of the future machine are cut. Profile pipes are used for the frame and pendulum, and a metal profile, a metal tire and a steel bar are used for cantilever mounting. If the design provides for a carrier platform, then sheet steel with a thickness of 4–5 mm is cut to size.

- To the pendulum lever, which is a segment profile pipe, weld the transverse axis (shaft) for the swivel. In this case, it is important to ensure the perpendicularity of the shaft attachment to the pendulum.

After cutting the material, a shaft is welded to the pendulum arm

- A U-shaped bracket is bent from a steel tire, holes for bolts are drilled in its sides, with the help of which the gearbox housing of the angle grinder is attached.

For fastening to the threaded holes on the angle grinder gearbox housing, you will need a U-shaped bracket

- An enveloping angle grinder U-shaped collar (ladder) and a clamping bar for fixing the tool body to the pendulum are made from a steel bar. The latter represents metal plate length, 15–20 mm greater than the width of the clamp. The threaded ends of the stepladder freely enter the holes on the edges of the pressure plate, and fixation is carried out with nuts with a suitable thread.

- Trying on a U-shaped bracket and clamp to a grinder, welding or threaded connection mount these parts on the console.

This is how the console for attaching the angle grinder to the pendulum arm assembly with a U-shaped bracket and clamp looks like

- The bearings that will ensure the rotation of the pendulum are pressed into the supports. As the latter, you can use both ready-made factory bearing units and pieces of steel pipe (15–20 mm) with a diameter equal to the outer race of the bearing.

- Bearing units are pressed onto the shaft from both sides. It is important that the connection is tight - this will eliminate unwanted longitudinal and transverse displacements. If the resulting connection is weakened for some reason, you can use the proven method - tin the axis with a soldering iron, applying a thin layer of tin to its surface (you will need soldering acid as a flux).

- At a distance of 50–60 mm from the edge of the platform, a pendulum assembly with support nodes is welded. It is important not to overheat the bearings, so these parts are wrapped in wet rags or constantly poured with water to cool.

The pendulum arm assembly with bearing assemblies is welded to the platform at a distance of 50–60 mm from the edge

- A console with an installed clamp and a U-shaped angle grinder is welded onto the pendulum lever. The position of the angle grinder is chosen based on personal preferences. There are different opinions on how to fasten the grinder ("on your own" or "on yourself"). Professional locksmiths work with the tool, orienting the sheaf of sparks towards themselves, arguing that if the grinder falls out of their hands for any reason, the tool will fly off in the opposite direction. Hobbyists most often work with medium or small grinders, so they prefer to have the disc rotate "from itself", as this allows control of the cut and prevents damage to clothing. When fixing the tool, do not forget to place the protective cover correctly - it should protect the worker in the event of a disc rupture.

- An angle grinder is attached to the assembled machine. Focusing on the weight of the tool, select and install the return spring. To do this, loops are welded to the frame and the pendulum or holes are drilled with a diameter of up to 5 mm.

In order not to damage the plastic body of the grinder, strips of rubber are laid between it and the brackets

- Perform a trial run grinder. First, check the operation of the machine in idle mode. At the same time, attention is paid to vibrations and backlashes of the working parts of the equipment, which, if necessary, are eliminated.

- Using a cutting wheel of maximum thickness, a groove is cut in the machine platform for the cutting disc. If necessary, the grinder is removed and the slot is expanded to the desired size.

It looks like an improved emphasis with a clamping device

At the last stage, stops for blanks are attached to the platform. Most often, two strips are provided (for cutting at an angle of 45 and 90 degrees), fixing them with a welded or threaded connection.

Often, fixtures for holding the workpiece are equipped with a measuring tool. By fixing a metal ruler on the stop bar with a reference point from the grinder disk, you can quickly and accurately cut off the part of the required length. Also, if desired, you can install protractors, a vice and clamps various designs. Such additional details allow you to make, for example, a full cut or groove in the workpiece at any angle, free your hands, and so on.

Do not forget to paint the fixture after all finishing activities have been carried out. Even a thin layer of enamel will protect the equipment from rust and make it appearance more aesthetic.

Video: How to make a cutting machine from a grinder with your own hands

Safety

In the process of working on a cutting machine (as well as during its operation in the future), safety precautions should be strictly observed. Be sure to use a protective mask or goggles, and position the angle grinder so that the sheaf of sparks is directed away from you. The high fire hazard of the equipment requires work in a ventilated area and away from fuels and lubricants. During welding activities, a protective mask, thick leather gloves, closed shoes and protective overalls should also be used.

When working with a cut-off machine, do not try to speed up the process by applying excessive pressure to the tool. At best, such a rush can result in a torn disc and a jammed clamp nut.

When using a welding machine, ensure good grounding and avoid operating the equipment with exposed cable sections. Remember that welding in open areas in rainy weather prohibited. As for the operation of the cutting machine, when arranging a button to turn it on, protect yourself by installing a simple decoupling with a 12-volt power relay. To do this, you can make a pedal with any non-latching switch (for example, a doorbell button) and use any solid-state relay rated for switching currents of at least 10A. A battery or accumulator with a voltage of 5 to 24 V is used as a power source.

A cutting machine from a grinder is a handy tool that can be easily made if you have the skills to work with electric welding and metalwork tools. A pendulum circular saw made in just one day will save time in the future and will allow you to perform plumbing and welding work precisely and accurately.