Insulation of interventional seams of a wooden house. Sealing wooden houses - popular methods and materials, experience of portal participants

A wooden house is not just a beautiful, environmentally friendly and comfortable home. Wood retains heat well, so if the sealing of a wooden house is carried out correctly, heating costs will be reduced by 30-40%.

Insulation of the house using the "Warm seam" technology

With the advent of new insulating materials, it became possible to insulate a wooden house more reliably and efficiently. The sealing of the log house using the “Warm Seam” technology is carried out just once, and the service life of such seams is more than 20 years.

The main material that is used to eliminate "cold bridges" in a log house is acrylic sealant. It is elastic, that is, the seam stretches or shrinks depending on the seasonal fluctuations in the size of the log house, perfectly seizes with wood and prevents moisture, dirt, mold, and pests from entering the joints.

The wood joint sealant is resistant to UV rays and temperature changes, does not emit toxic substances and can be safely used even indoors. The interventional sealant for wood can be painted in different colors, so that the seam becomes unique decorative element log house.

ADVANTAGES OF WARM SEAM TECHNOLOGY

Sealing allows you to optimize the temperature and humidity conditions for living in the house

The absence of heat leakage from interventional gaps will reduce the cost of heating a wooden house

Sealing allows you to reduce costs and refuse additional investments in periodic caulking

Sealed interventional gaps will avoid blowing through the log walls of a wooden house in wet and cold weather

Airtight openings prevent insects and mold growth in the openings

A wide range of colors and textures of the sealant, combined with wood, improves appearance your house

Warm seam prices for services for a wooden house

*The cost of all materials is already included in the price of the work.

| Warm seam for logs | |

|

diameter up to 220mm |

*150 rub. per running meter |

| diameter up to 260mm | *170 rub. per running meter |

| diameter up to 300mm | *195 rub. per running meter |

| Warm seam for log house | |

|

from *195 rub. per running meter |

|

| Preparing for a warm seam | |

|

Removal of an old caulk from 20 rubles. per running meter |

|

| Removal of old sealant from 40 rubles. per running meter | |

Why is it cold in a wooden house?

Any wood under the influence of the environment changes its parameters over time. Cracks form between the logs, drafts begin to walk in the house, and the heat leaves. Our ancestors were well aware of this feature of wood. Therefore, the caulking of a wooden frame was an important stage in the construction. The space between the crowns was densely filled with moss. The first time is in the process of construction, and the second time - a year later, when the log house "settles".

So in most cases they do now, only warming wooden houses produce tow, jute, linen. natural materials they look nice, protect the joints well and keep warm. But they require regular updating, since the insulating material cannot fill the increasing gaps, it is blown out by the wind, birds take it away, and insects can settle in it.

A new technology for insulating a house with sealants for wood, which is used by the company " Warm house, is devoid of all these shortcomings.

REMMERS sealant color palette

How is the insulation of the log house with sealant?

The warming of the log house using the “Warm Seam” technology is carried out 1-1.5 years after the completion of construction, when the process of shrinking the house is completed. The technology includes several stages:

- The seams between the logs are prepared for processing: the old insulation is removed, the cracks are cleared, dust and dirt are removed, and they are coated with a special impregnation.

- The prepared surface is primed.

- A sealing cord is laid, which fills deep gaps and cracks, creating the basis for a layer of sealant.

- Using a pneumatic mechanism, the seams are filled with sealant, which is leveled with a spatula. The recommended joint thickness is 4-6 mm.

- The joint is finalized by smoothing the surface of the sealant, giving it a neat appearance.

- Within 2-7 days, the sealant hardens. The curing time depends on the initial moisture content of the wood and the ambient temperature.

It is better to entrust the warming of a wooden house with a warm seam to professionals. The specialists of the company "Teply Dom" will help you choose the most suitable type of sealant, and our masters will quickly and accurately carry out all the work.

We use only the best, proven sealants from RAMSAUER (Austria) and other leading manufacturers. This allows the customer to guarantee the high quality of the seam, the absence of "cold bridges" and the long service life of materials.

FAQ

- Can I trust you with my house? "Teply Dom" has been on the construction services market for more than 6 years and during this time there has not been a single dissatisfied client. All work is carried out "in white" in compliance with all technologies.

- Hope you are doing a good job. What guarantees can you give? The quality is guaranteed by the contract. We also provide a Guarantee on the quality of work performed up to 7 years for all work done.

- Do I need to buy materials and take care of the garbage? No, we do turnkey work: we take care of the purchase and delivery of materials. The site is guaranteed to be clean. We also take out the trash ourselves.

- Who will directly carry out the work? We have our own builders. All workers are qualified, trained specialists, Slavs.

Shrinkage processes occurring in a wooden structure during the first years after construction inevitably lead to the formation of cracks. Previously, there was only one way to insulate a log house - caulking. Today, many owners of wooden houses prefer traditional caulking more modern way thermal insulation technology "warm seam". This technique allows you to qualitatively and quickly isolate the gaps formed in the inter-timber seams of logs during the shrinkage of the log house. Usually, specialists are hired for this work who competently and professionally perform sealing. In this review you will find practical advice, how to make a warm seam for wooden houses with your own hands, and also find out what typical mistakes are most often made by non-professional craftsmen.

There are several types of sealants that can be used to insulate interventional seams and crevices:

There are several types of sealants that can be used to insulate interventional seams and crevices:

- acrylic;

- silicone;

- polyurethane;

- bituminous.

The most popular of the presented types is the acrylic composition. Among its advantages are:

- elasticity;

- good adhesion;

- moisture resistance;

- biostability;

- color fastness;

- simplicity and ease of application.

Silicone-based sealant withstands high temperatures and humidity well, so it is often used to seal gaps in the bath and sauna.

The polyurethane composition also has decent characteristics, but due to the fact that it contains toxic components, it can only be used for external insulation.

Bituminous mastics have a very high degree of moisture resistance, so they are usually used to seal the dampest places: basements, basements and roofs.

More detailed characteristics of acrylic and other types of sealants can be found in the article.

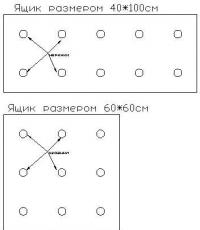

Types of packaging

Sealant is available:

- in cartridges. Such packaging is intended for use in special construction guns.

- In tubes. The mass is squeezed out of the tube directly onto the seam, and then it is attached to it with a chisel desired shape. Alignment is carried out within 10 minutes after application, otherwise the sealant will polymerize and it will be quite difficult to correct the frozen shape.

- In plastic buckets. In this case, the sealant is applied with a spatula.

Log and timber houses can be insulated no earlier than 1-2 years after construction. The exception is houses made of glued laminated timber, which can be sealed almost immediately after construction.

Log and timber houses can be insulated no earlier than 1-2 years after construction. The exception is houses made of glued laminated timber, which can be sealed almost immediately after construction.

To achieve the maximum effect, sealing is desirable to carry out outside and inside the house. However, only external thermal insulation of joints is also allowed.

Sealant can be applied only in dry weather at a temperature not lower than 5 degrees Celsius.

If work is carried out in the summer in hot sunny weather, the shady side is sealed first. With the active sun, the sealant dries quickly, which is undesirable, as the technology is violated.

When applying a sealant to a previously painted surface, it is necessary to first carry out an adhesion test with a dye on a small area.

Seam Sealing Instructions

Effective insulation can only be obtained with strict adherence to technology. Sealing includes several mandatory steps that must be performed in strict sequence.

Required Tools

To perform the work, in addition to the sealant, you will need the following materials and tools:

- putty knife;

- construction pistol;

- primer composition for wood impregnation;

- polyethylene cord for sealing wide gaps;

- an aqueous solution to moisten the spatula blade when leveling the seam;

- brushes;

- masking tape.

Preparatory operations

The walls of the log house must be thoroughly cleaned of dirt and dust. If the sealant will be applied to a new house, then it is necessary to remove the old paintwork. If the seams were previously caulked, you need to remove the old caulk.

The walls of the log house must be thoroughly cleaned of dirt and dust. If the sealant will be applied to a new house, then it is necessary to remove the old paintwork. If the seams were previously caulked, you need to remove the old caulk.

To improve adhesion, the surface to be treated is primed before sealing. The primer is made from a mixture of water and sealant in a ratio of 10:1. Then, in the resulting solution, a brush or rag is moistened and the joints of the logs are wiped. After all preparatory activities dry the surface well.

Preparation is an important step in sealing. An insufficiently cleaned surface prevents adhesion, the sealant will lie unevenly and lag behind the walls.

It should be noted that wood preservative is carried out after applying the sealant. Antiseptic compounds dramatically reduce the adhesion of materials.

Application of sealant

- To prevent the composition from getting into areas that are outside the application area, masking tape can be glued to the side faces of the logs. Usually this operation is done when the work is done by non-professionals. Experts apply sealant without adhesive tape exactly in the right places, covering an area of 1.5-2 m in one pass, but such accuracy comes with experience.

- A sealing polyethylene cord is placed in the gap between the interventional seams with the help of a chisel, which tightly fills the openings and at the same time serves to save the sealant.

- A warm seam is applied with a gun to the joints of the logs. It should capture the surface of the logs by 0.5-1 cm on each side.

- Then the seam is slightly sprinkled with water and leveled with a spatula, while removing excess sealant.

- After that, the final alignment is performed. To do this, use a brush slightly moistened with water.

- Then they carefully wipe with a rag on both sides of the warm seam, removing the stains left after the water. If this is not done immediately, the stains will harden and then it will be quite problematic to remove them.

- After finishing work, remove the adhesive tape.

For complete drying, the sealant takes two weeks, after which it can be coated with paints and varnishes. When using an acrylic composition, you must also use an acrylic dye.

Self sealing errors

Non-professional craftsmen, when performing sealing of interventional seams of a log house on their own, inevitably face problems. To properly do the work yourself, you need to know certain subtleties and nuances.

Among common mistakes, which are most often performed by untrained masters, can be distinguished:

Among common mistakes, which are most often performed by untrained masters, can be distinguished:

- Wrong choice of sealant.

- Performing work in inappropriate weather conditions.

- Violation of work technology.

- Poor preparation of the surface, as a result of which the sealant does not fit well and lags behind the wood.

- Careless application of the composition, which is why the warm seam looks rough and sloppy.

So that the warm seam is made with high quality and neatly, and serves you long years contact the professionals.

The company "Mater Srubov" has many years of experience in insulating houses from timber and logs using the "warm seam" technology. In our work, quality indicators are the main priorities. We employ experienced craftsmen who are highly qualified. Our company has established a two-level system for checking the integrity and quality of the work performed, which is carried out by the construction supervision department and the quality control department.

By entrusting us with the sealing of your home, you can be sure of an excellent result. You can contact us at the coordinates on the page.

Due to the ability of wood to "breathe", in wooden houses creates a special microclimate. However, the flip side of the coin is the gaps at the seams and cracks that appear during operation. How to restore the tightness of the walls and minimize heat loss - let's deal with the craftsmen of FORUMHOUSE. Consider:

- Why do wooden walls need grouting?

- What is a caulk.

- What is a warm seam.

Do you like to ride, love to carry sleds, or why wooden houses require attention

Wood is not only the most environmentally friendly construction material, but also the most deformable - it shrinks, cracks, changes geometry with a change in humidity. Log cabins made of chopped or rounded logs, as well as timber are especially susceptible to these phenomena. natural humidity. In the process of assembling a wooden box, interventional insulation is necessarily used, which is laid in each row, but it is not enough to completely seal the seams.

As the shrinkage increases, the thickness of the seams between the log / beam increases, and through them not only heat escapes from the house, but moisture also gets inside the walls.

It is fraught with extra costs for heating, as well as a decrease in the strength and durability of the structure. Therefore, after a while, the interval depends on both the quality of the lumber and the quality of the assembly; sealing of seams and cracks is required. Today, two methods of sealing wooden walls are in demand - caulking and a warm seam.

Caulker

The traditional way of processing seams - with the help of special devices, the grooves are filled as densely as possible with natural insulation with the formation of a small roller on the front side.

The walls are caulked both outside and inside, this method not only allows you to get rid of cracks and minimize heat loss, but also increases the decorative effect. From ancient times, moss was used for caulking, which simultaneously served as an antiseptic, but today other natural materials are more often used - linen, felt, tow or jute.

Primary caulking is carried out simultaneously with the assembly of the box - a wide interventional insulation is used and a roller is formed from the protruding edge and hammered into the seam.

The next treatment is carried out after shrinkage and polishing of the log house, the best option is two years later (OCB) or one year later if settlement is planned earlier. But in this case, after the first heating season repeat may be required. For many, the question that worries one of our craftsmen is relevant.

glyuck FORUMHOUSE user

Long read the topics on the forum, but did not come to a consensus. Now the log house is being polished, I thought then to caulk and paint. Cut 1 year. But many write that it is better to caulk a year after installing the heating, so that the logs dry out, otherwise caulk again. What about winter heating costs? How to do it better?

According to experienced forum users, it's worth the wait.

Carpenter29 FORUMHOUSE user

The most optimal solution is to caulk after two heating seasons.

Another option.

IPaltus FORUMHOUSE user

Now tuck openly dubious places, turn on the heating and caulk for the second or even third year.

Of course, you will have to heat the street, but it is justified.

avsergeev71 FORUMHOUSE user

Believe me, the cost of re-caulking (and in this case you will definitely have to do it) will not be comparable to the cost of the heating season. As for the year - I would wait not a year, but two.

So that heat losses are not critical, and blowing through the seams does not replace ventilation, at the assembly stage you should not save on interventional insulation. glyuck can afford to wait just thanks to a responsible approach.

glyuck

So I will do it, I decided in time not to caulk now. Moreover, my log cabin was laid on the thickest superjut, and each log was rammed with a huge sledgehammer. Now everything is already quite tight, but in any case, in two years I will caulk, as you advised.

Houses assembled from a simple bar of natural moisture are also subject to shrinkage, although to a lesser extent than log houses. During the assembly process, interventional insulation is also used, and caulking is carried out on average after a year and a half.

Warm seam

A warm seam is also used in houses made of chopped or rounded logs, and in houses made of ordinary, profiled and glued beams. This technology is especially common precisely for profiled timber of natural moisture, since it is difficult to caulk due to the interlock, and there is a need for sealing the seams. A properly assembled glulam box gives minimal shrinkage and in most cases no additional grouting is required in the walls. But if such a need still arises, a warm seam is the best option.

This is a modern technology that involves the use of synthetic materials - polymer filler and acrylic sealant. The filler is an elastic cord made of polyethylene foam or a thin tape, the cord is used to fill thick seams and crevices, the tape is used for narrow ones. On top of the cord / tape, the seam is filled with sealant, the layer thickness is from 5 mm.

The composition is characterized by high adhesion to the surface and elasticity, it completely seals the seam and adapts to the seasonal deformations of the wood.

Not everyone understands why to use cord/tape.

Vladimir_Ilich FORUMHOUSE user

Tell me, is laying a sealing harness before sealing a necessary technical process, or is it a personal choice?

Holtzschutz FORUMHOUSE user

Of course, it’s a personal choice: either you do it as it should, which means it’s economical, checked by properties, productive and beautiful, or whatever you want, in the range from “I’ll figure it out myself” and “I think these details are superfluous”, to “a neighbor did it yesterday, he says that forever." We are satisfied with both options: in the first case, we see a satisfied client, in the second case, sales for the same house immediately double, and in a couple of years the client is again a buyer.

With old tow, you should be careful.

Interhouse FORUMHOUSE user

The sealant should stick only to the top and bottom log/beam, and then it will work in tension and compression. If he sticks to the tow, then he, together with the tow, will fly out of the seam over time. Therefore, we first either knock out the old tow or cut it off, then lay the foam polyethylene cord (the sealant does not stick to it), and then we apply the sealant.

Some believe that it is realistic to do without a sealant.

Pilotajnik FORUMHOUSE user

Regarding the sealing harness: if the house has “settled”, put it where there are gaps. Where there are no gaps between the logs, it can not be laid, but this is subject to the complete shrinkage of the house. There are examples of houses on which sealing was carried out exactly according to this principle 5-6 years ago, and there are no problems.

Like natural materials used for caulking, acrylic sealant is permeable, it prevents moisture from entering the seams from the outside, but does not clog them.

A warm seam is performed after grinding the wood and treating the walls with antiseptic compounds.

Depending on the manufacturer, sealants are available both tinted and neutral, for subsequent painting with specialized oils, azures or waxes. Considering that a high-quality sealant is designed for 10-15 years of service, protective and decorative coatings require updating more often, it is worth choosing specialized compounds that do not require wood grinding before application.

Interhouse

"Long-playing" paints are remarkable in that they are updated after 5-7 years without grinding, with 1 layer of the same paint / oil / impregnation. I do not recommend varnish, precisely because the wood is covered with a film. And after a few years you will have to grind, because the paint simply will not be absorbed, this is at best.

The technology for applying sealant depends on the form of release, plus each manufacturer gives its own recommendations, but to make the seam not only tight and durable, our craftsmen can give some advice.

Sibman22 FORUMHOUSE user

After applying the sealant, always used several metal spatulas to match the size of the joint. Smoothing with a spatula allows you to maintain the uniformity of the seam, both in thickness and in width. The existing surface roughness was smoothed out with an ordinary kitchen sponge moistened with water. With it, we also remove jambs, smears and blunders from the log (we immediately wash it in a bucket and use it further). The use of a sponge allows you to make a visually smooth transition between the sealant and the wood and does not leave clearly marked borders of the seam contour.

Hand-modified rubber spatulas are also suitable.

Nata-K FORUMHOUSE user

These spatulas were made by us, they helped a lot in the work, there was also a very soft 25 mm brush.

Buildings from natural wood exposed to the negative effects of precipitation and temperature. The material shrinks, which leads to cracks. To prevent the formation of gaps and improve the thermal insulation of the room, a warm seam wood sealant is used. It helps to eliminate defects in natural wood and protect the structure from the cold.

Insulation of joints in a wooden frame has a number of features and differs from sealing joints on concrete, brick, metal bases. The use of familiar materials is not always appropriate, since it requires periodic replacement. Thermal insulation cannot 100% protect joints. The use of a warm seam for a wooden house creates an effective barrier against cold and moisture.

The essence of the method:

- space between wooden elements caulk with any heat-insulating material laid flush.

- A special Vilaterm cord is laid over the insulation, which protects the inter-seam sealant from contact with the thermal insulation.

- A warm seam is applied to the laying cord - a sealant based on acrylic, silicone or polyurethane.

The sealant is easily and accurately smoothed, forming even and uniform seams in width. They can be dyed with colored or transparent paintwork materials. Reliable protection using warm seam technology well prevents blowing through the house.

Attention! A warm seam does not replace heat-insulating materials for caulking, but complements them. You can not apply a warm seam if insulation and cord are not laid between the logs. Otherwise, the sealant will crack, crumble and begin to fall out.

Materials and tools

Before applying a warm seam for a wooden structure, you need to prepare for work and calculate the consumption of sealant. If the log house is not yet caulked, you need to seal all the joints with heat-insulating material - tow, foam, foamed polyurethane, jute, and other insulation.

To seal joints using the warm seam technology, you need:

- Composition for wood, produced in cartridges.

- Construction gun for sealed tubes.

- Foamed polyethylene Vilaterm without holes.

- Spatulas with different widths of the working surface.

- Paint brushes up to 30 mm wide for painting.

- Adhesive tape for gluing areas along the length of the joints.

- Clean water, rags to remove excess weight.

The use of a pneumatic gun speeds up and simplifies the work. The tube with sealant is firmly fixed in the installation tool. The mixture is easily squeezed out in dosed portions. To evenly fill the seams, you can use guns various types and designs.

Sealant selection

Compositions for sealing joints in wooden structures are presented in a large assortment. The most popular brands are mixtures produced by Eurotex, Neomid, Remmers. The compositions can be used for interventional seams, truss system, window frames, door frames, wooden stairs and run interior decoration interior. To make a warm seam, you need to choose sealants that are resistant to deformation, temperature changes. Mixtures should have good adhesion and a long service life.

Varieties of interventional sealants for wood:

- Silicone products on a neutral or acid basis. Suitable for wooden surfaces, have an impressive operational resource (20-25 years). Paint silicone sealant you can’t, there are ready-made color mixtures on sale. A suitable product is BARTON'S Warm House interventional sealant.

- Polyurethane compounds have optimal strength and good adhesion, but are more expensive. Mixtures withstand mechanical stress, are not "afraid" of moisture and chemicals. After complete drying, the mixtures do not shrink, can be stained, but do not have sufficient resistance to ultraviolet rays.

- Acrylic sealants for wood are most often used. Non-toxic environmentally friendly products adhere perfectly to porous fibrous wood. The composition of sealants does not include solvents. After polymerization, acrylic sealant warm seam is painted "under the tree".

When choosing a means for sealing the joints of wooden structures, preference should be given to proven compositions of well-known brands. In table. 1 shows the most popular formulations and their main advantages.

Table 1. Sealants for wood warm seam

| Name | Composition | Main advantages | Peculiarities |

| BARTON'S "Warm House" | Silicone | Elastic, does not shrink | Additives for rotting pests |

| PU-25 | Polyurethane | Good adhesion, waterproof | Large temperature range |

| Neomid Warm House Wood Professional Plus | Acrylic | Elasticity and elasticity of seams, tear resistance | Low fluidity, rich color gamut |

| PERMA CHINK | Acrylic | Fast setting, convenient packaging | small consumption |

| Energy Seal | Acrylic | Resists deformation well after curing | Treatment of narrow seams up to 2.5 cm |

| Remmers Acryl 100 | Acrylic | Resistant to compression, stretching, UV | Long service life of 20-25 years |

| EUROTEX | Acrylic | Processing of all types of wooden structures | 3 wood shades |

| Neomid Wood Professional | Acrylic | Elasticity up to 300%, sealing the joints of log cabins | Holds heat well |

| Zobel | Acrylic | Accelerated curing, interventional joints | 3 composition warm seam |

| EurAcryl | Acrylic | Resistant to water, UV rays | Extensive area of use |

| Ramsauer Acryl 160 | Acrylic | Adhesion with different bases | A protective film forms quickly |

Note: C inside it is recommended to process logs with an acrylic sealant warm seam. Environmentally friendly product does not emit harmful substances, does not have toxicity.

Price

Sealant prices vary widely. The cost of products is influenced by the popularity of the brand, the place of production (domestic or foreign companies). To perform large-scale work, it is recommended to buy sealant in a capacious container. It's cheaper than buying several compact tubes. The average consumption of 600 ml of the composition in the cartridge is 4-6 m. The cost of the popular German Remmers product is 430-450 rubles.

Eurotex sealant is supplied in plastic buckets of 25 kg, at a price of 7,000 rubles. But with such a quantity of the mixture, 250 m3 can be processed. seams.

To process a wooden frame in a new way modern technology warm seam, you need to follow certain rules and recommendations from the masters.

The process of sealing joints can be divided into several stages:

- Cleaning the gaps from dust and debris, sealing the seams along the length with masking tape.

2.Laying thermal insulation material to fill the interventional space.

3. Laying a special Vilaterm cord, which limits the contact of the sealant with the insulation.

4. Applying a warm seam to the joints using a construction gun according to the principle of processing seams with mounting foam.

5. Removal of excess mass at the seams of a log house of a wooden structure with a damp rag or spatula.

After sealing the seams with an interventional sealant, you need to form perfectly even and smooth seams. To do this, with a small brush dipped in clean water, gently smooth out the warm seam. To finally align the joints, they are passed over them with a damp cloth or foam rubber sponge.

On video: How to make a "warm seam" with interventional sealant.,

Corners and cuts

The most difficult thing to do with your own hands is sealing using the warm seam technology at the junctions of wooden walls. To carry out the processing of corners and cuts, a cord of the required length is laid in the joints, pushing the material into the middle with a narrow spatula. After that, a warm seam sealant is applied and the mass is leveled. The work is painstaking and time-consuming, but the tightness of the entire wooden structure depends on the quality of sealing the corners.

Attention: wooden walls treated with impregnations and flame retardants with solvents and oily inclusions, on which the sealant does not adhere well. Masters recommend pre-cleaning the top layer of wood with a grinder, hand grater or sandpaper. Surfaces coated with water-soluble impregnations do not need to be sanded.

For owners of wooden houses, the problem of insulation using warm seam technology is always relevant.

Therefore, users often ask questions related to this topic:

- Will there be any benefit from applying sealant to caulked joints? - Subject to the technology of a warm seam, the effectiveness of the method is very high.

- When to remove the excess hermetic mass that has fallen on the surface of the logs? - It is desirable to remove the remains of the mixture immediately, until the composition begins to dry out.

- Which warm seam is better to use - internal or external? The best option- double-sided processing of a wooden structure to improve waterproofing characteristics.

One more frequently asked question- Is it allowed to perform work in the cold season at a negative air temperature? - Outdoor work in frost can only be carried out with some compositions, for example, Accent-136.

Reviews

According to the owners of wooden houses, the warm seam technology works one hundred percent. Heat is better retained in the rooms, and the building itself takes on a more attractive appearance. The process of applying a warm seam takes a lot of time. It takes at least two weeks to close up the external joints in a house of 100 m2. Full processing at a cost of 10,000-15,000 rubles. Users are advised not to apply the product in a thin layer so that the sealant does not come off the wood. According to reviews, doing the work yourself costs two times cheaper than using the services of professionals.

The technology of using sealant warm seam (2 videos)

Types of sealant warm seam (25 photos)

CREATOR: gd-jpeg v1.0 (using IJG JPEG v62), quality = 100

CREATOR: gd-jpeg v1.0 (using IJG JPEG v62), quality = 100

Development of technology for sealing the walls of panel-type houses

The first large-panel housing construction appeared in Europe in the 20s of the last century, the speed and cheapness of construction made this type of construction especially common in the socialist countries by the 60s and 70s. The mass construction of Soviet cities and towns with a series of large-panel houses made of materials produced by numerous house-building factories, despite all the shortcomings of this development in aesthetic and architectural terms, has improved their living conditions for millions of families. There are no analogues in the world of such a large-scale construction of sufficiently comfortable and modern housing; from a predominantly agrarian and peasant country, the USSR in a short time turned into a power with a significant predominance of the urban population. The "Warm seam" technology in Western countries is mainly used in the construction of wooden buildings, in Russia a warm seam is more often a technology for repairing and sealing joints between panels in panel buildings. A warm seam can significantly improve the performance of buildings even in the Russian climate. In the Moscow region, it is widely used by the Directorates of a Single Customer (DEZ), as a type of repair sealing during current and overhaul joints.

Causes and consequences of the destruction of interpanel seams

During the construction of the building, the inter-panel joints are sealed and protected, but in the first few years of operation of the building, inevitable shrinkage occurs. wall panels, shift of panels in case of uneven settlement of individual parts. The dimensions of these deformations are about 30 - 35% of the deformations that are caused by temperature effects, which also inevitably produce an adverse effect on the sealant. Stretching-compression from temperature fluctuations and changes in air humidity is not the only adverse factor; environmental factors such as icing, "acid rain", and UV irradiation affect the sealant at the junction of panels. IN middle lane In Russia, the total opening of sealants in the joints of panels is 4.5 - 5 mm per year. As a result of this natural aging, the average life of a polyurethane sealant before complete loss performance characteristics is not more than 15 years.

The main and most serious problem of panel buildings is the destruction of the seams and the deformation of the interpanel joints, which reduces their service life. The consequences of this are expressed in the freezing of the outer panels in winter, and in the flow of walls during precipitation. A much more unpleasant consequence of a violation of the tightness of the joints is the complete destruction of the enclosing structures of buildings, the reinforcement of panels connected by welding. The metal frame of reinforced concrete, according to research results, will rust by 0.3 mm per year if exposed to direct weathering. The danger of spontaneous destruction of any part of the walls, which will lead to an emergency state of the entire building, a real threat to the safety of people in the building or next to it.

Sealing of interpanel joints using the "Warm seam" technology

Sealing of interpanel joints during repairs takes place mainly from the outside of the structure, does not require the resettlement of residents and often does not cause them any inconvenience at all. High-altitude repair work can be carried out using scaffolding, aerial platforms, and with the help of industrial climbers. The latter method is often the most optimal, especially since the sealing of interpanel seams by industrial climbers allows work without a comprehensive repair of the entire house, the outer walls of a single apartment can be sealed, .. An industrial climber has considerable freedom in actions at height, not limited by fencing a scaffolding site or booths, because the quality of their work is usually higher. Sealing works at height are also resorted to when processing newly installed plastic windows, canopies, balconies, loggias, etc. Industrial mountaineering is a rather dangerous job, the industrial climber must be able to work with climbing equipment, clearly know the methods of insurance and first aid in emergency situations. Persons who have undergone the necessary instruction, medical examination and special training, with state-issued certificates from a licensed Ministry of Education, are allowed to work with it. educational institution. Retraining of industrial climbers takes place at least once every 2 years.

Repair work on the restoration of the sealing of interpanel joints using the "warm seam" technology starts with the processing of the joints - they are cleaned by hand from dirt, paint residues, traces of old sealant, and areas that have peeled off with the remains of the solution. Then, if necessary, the cracks are patched and sections of the concrete facade are restored at the points of contact of the outer panels. The procedure for isolating the seams is carried out, since sealing the seams, if quality is at the forefront, is possible only on a completely dry edge of the joint. A completely and thoroughly cleaned and completely dry joint is filled with polyurethane heat-protective sealant. When it hardens, it expands and fills all voids. On the non-hardened sealant along the entire length of the joint, without gaps and slightly lower relative to the surface of the facade, a heater is laid - porous or hollow material, and is compressed by 15-50%. The final phase of sealing the seams is the coating of the joint cavity with a special mastic. Mastic will protect the joint from solar radiation. Wide joints may require repeated procedures for filling the cavity of the joints. Sealing and thermal insulation is carried out at temperatures from +35 to -15 ° C. The technology of "warm seam" in the construction of wooden buildings is usually limited to a special sealant, without sealants, but for panel structures, the use of elastic porous sealants is mandatory.

Sealants

Sealants used in the repair of interpanel joints using the "warm seam" method differ in the material of the polymeric binder base - either silicone (organosilicon) sealants, or polysulfide (thiokol), acrylic, polyurethane. The silicone sealant cures on contact with air and is resistant to extreme temperatures and harsh environments. However, it is not very elastic, is afraid of deformation and often collapses at the point of stress. It is not universal, contains a solvent, and interacts (sticks) differently to various building materials. In addition, silicone sealant cannot be painted, and its cost is quite high. Acrylic sealants are rarely used when sealing joints from the inside, as they are deformed by temperature changes and are afraid of moisture. Polysulfide (thiokol) sealants are used to seal interpanel joints, but they require a special preparation technology, as they are two-component. Polysulfide (thiokol) sealants are weakly resistant to deformations and the seams closed by them "slip" and blacken, which does not decorate the appearance of the building. Thiokol sealant can only be applied at temperatures above -10°C. Polyurethane sealants are universal, durable and elastic, polymerize in air, do not shrink during vulcanization. Sealant consumption can be accurately calculated, they stick to any material, and you can work with them under any conditions. Interpanel joints sealed using the "Warm joint" technology on polyurethane sealant are durable and of high quality.

Mastics

Light-protective mastics are used to protect polymeric materials from UV radiation. Usually these are two-component systems of cold curing on polyurethane. After connecting the components, the mastic looks like a creamy paste, easily applied to the sealed joint, and over time, the mastic becomes a mass similar to rubber. Adhesion (sticking ability) of polyurethane mastics to concrete, cement-sand mortar, polymer sealants and other metal materials is very high. The mastic seizes for a period of 2 to 5 hours, finally elastic (8-9 kg / cm), elastic (600%) and a strong structure is formed in up to 14 days. The polymerization of the mastic takes place due to contact with atmospheric moisture, and therefore air humidity and water in the joints greatly affect the quality of the sealing. It is advisable not to allow moisture to enter the mastic, this leads to the appearance of bubbles in the structure, since polymerization proceeds with the release of gas, which causes all the cavities of the construction joint to be filled with mastic.

Disadvantages of "Warm Seam" technology

These include the rather high cost of repairs that are performed manually with difficult conditions and hazardous conditions. Porous insulation using the "warm seam" technology can absorb moisture, and it, in turn, will cause the destruction of the material. Thorough sealing cannot always be guaranteed, since the insulation may be unevenly distributed in the groove of the seam, and in the future it is impossible to determine the place of leakage.

Sources, standards

Regulatory documents: SNiP 3.03.01-87 "Bearing and enclosing structures" (Gosstroy of the USSR 04. 12. 1987 N 280, changes from 22.05. 2003). Interim safety rules in industrial mountaineering dated 06/09/2001, "Interdepartmental Commission for the certification of emergency rescue teams, rescuers and educational institutions for their preparation"

Links

VSN 54-96 Instructions for the technology of sealing and thermal insulation of joints of panels, window and door blocks using "Macroflex" in residential buildings during repair