How to make a wooden tool box. How to make a tool box: choose a shape and drawing for self-production What is the name of a wooden tool box

For quick access to the toolkit, you should properly organize the storage system. An organizer and a tool box help to cope with this. With their own hands they are made from solid wood, plywood, chipboard, various kinds plastic and tin.

The material is selected based on the size of the product and the skills of the carpenter, each has its own advantages and disadvantages.

Home varieties

For stationary storage of tools, open or closed stands and spacious chests of drawers are suitable. In these options, it all depends on their location - a garage or an apartment. In the first case, it is more convenient to organize a stand of the right size on the wall so that everything is open and freely available.

For apartments, designs with shelves or plywood drawers, cabinets and even a suitcase are suitable. They can accommodate organizers and cases for power tools and hardware. Small stands can be built on the doors and side walls. The more correctly organized the filling, the longer the order will be maintained.

To accommodate the main set of tools, wrenches, heads, bolts and nuts, a small container with a handle can act as mobile options. With large dimensions, wheels can be screwed to it. Then you should choose the material, calculate the acceptable dimensions, choose the model and type of fasteners, draw up a drawing for the tool box with your own hands or use ready-made offers. After that, you can start manufacturing.

In addition to safety, a do-it-yourself tool box helps with the work. Its sorted content, when each item is in its place, allows you to eventually find everything you need without even looking inside.

The standard placement of a hammer, wrenches and pliers occupies one large compartment. Screwdrivers are inserted into the holes on the horizontal bars.

Classic drawer options

This kind of do-it-yourself tool case is easy to perform. The accessories of the main set lie in sight, each in its place. It is useful for transfer outside the workshop. Tool carriers tend to be heavy, so don't make them too big or made entirely out of planks. Some parts can be replaced with plywood.

open with baffle

Before starting work, make sure that the workpiece material is dry. For the first version you will need the following materials and tools:

- pine boards;

- plywood;

- thermal or PVA glue;

- nails and screws;

- hacksaw, jigsaw or grinder;

- drill or brace and drill for wood;

- a hammer;

- chisel;

- tape measure or ruler;

- pencil or marker.

Plywood or cuttings of pine boards are suitable as a material. According to the drawing, markings are made and blanks for the body are cut. Special grooves are cut out in which the partition will stand. To organize them, you will need a milling cutter or a hacksaw with a chisel.

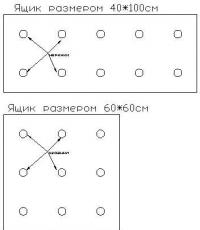

The drawing shows the classic dimensions that are optimal for assembling the box. All blanks are cut according to the scheme, when changing one parameter, it is necessary to proportionally subtract or add from the others:

- transverse walls - 2 pcs.;

- sidewalls - 2 pcs.;

- partition groove.

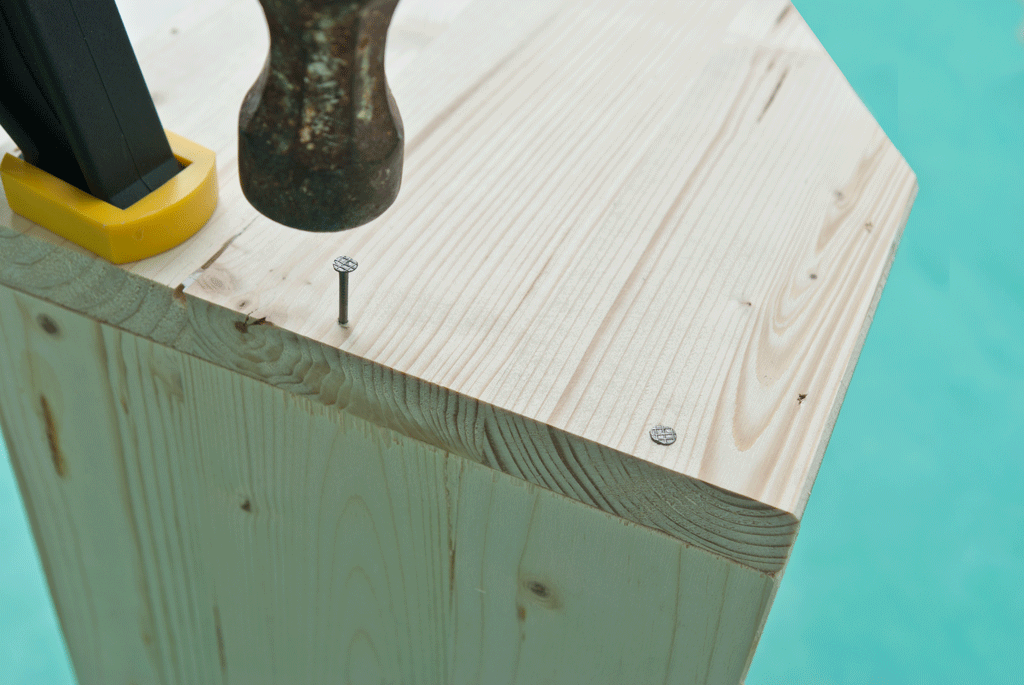

Sand all prepared elements, assemble a rectangular box. To prevent the structure from falling apart, the attachment points and the ends of the blanks are coated with glue. Additionally, the box is knocked down with small nails or twisted with screws.

In the upper part of the plywood blank, a handle is cut with a hacksaw, jigsaw or grinder. Prepared grooves are lubricated with glue. After that, a partition is installed in them.

From the blocks are made pads for the handle. The corners of the workpieces are processed with a planer and sandpaper, fastened with glue or cloves. From wooden slats, cut to the size of the partition, you need to make holders that are placed horizontally on the partition. Suitable holes are drilled for screwdrivers with a drill. Pliers, wire cutters, etc. are placed in rectangular grooves.

The entire structure must be covered with a protective compound. To do this, you can use varnish or paint material with special additives.

Organizer in a stool

With this design of the organizer for tools with your own hands, you can carry the tool to the right place and sit on it and reach out to a place that is slightly higher than your height. Materials and tools are the same as in the previous case. Cut out of plywood:

- Cover 550x380 mm with a cutout in the center 140x40 mm.

- Longitudinal drawers 470x150x540 mm and a bevel angle of 75 °.

- Two sidewalls 306x380 mm.

- The legs and handle are made of bars 385x40x50 mm. At the ends, saw off the bevels at an angle of 15 °.

Assembly is done with screws. Sharp corners are rounded with sandpaper. The product is cleaned of dust and covered with a protective composition.

Type of homemade carrying

If you want to make something more elegant with embossed forms of the side racks, this homemade tool box is just right. First you need to take boards with a thickness of 16 mm. Make parts from them, as in the diagram, and take a round aluminum stick or other metal tube.

Along lines parallel to the edges, holes are drilled on the side walls for self-tapping screws to fasten the structure. With sanding paper or an electric machine, burrs are removed and sharp corners are smoothed out. After that, the prepared parts are assembled: the bottom and sides are fastened with glue and screws.

Using the same marking method, vertical racks are installed, between which a horizontal handle is fixed. Screwdriver holders are screwed with self-tapping screws. The entire surface is cleaned of excess glue and dust.

For protection, the product is varnished or painted. After drying, the box is ready for use.

The various designs of tool boxes discussed in the article are united by the ease of doing it yourself. Choose the right project and, guided by our drawings and photographs, make yourself a convenient portable storage for the tools and equipment used in your work.

simple open box

This box is good because the tools in it are located in their places and are in sight. You can’t put many devices in it, but there is a place for the main ones. An open box is useful in household use when you need to repair something outside the workshop: they reported to the box what was missing and went to work.

A wooden tool carrier comes out heavier than factory counterparts, so you should not plan it too bulky. The box will not beat the knees if you make it narrow. The high handle also adds convenience - you don't have to bend down low to pick it up.

Pick up suitable pieces of plywood and pine board trimmings. Mark and cut out the details of the box. Select the grooves in the blanks with a hand router or make two cuts with a circular saw and clean the recess with a narrow chisel.

Details of the box body: 1 - wall (2 pcs.); 2 - sidewall (2 pcs.); 3 - bottom; 4 - groove along the thickness of the partition and a depth of 1/2-1/3 of the thickness of the material

Details of the box body: 1 - wall (2 pcs.); 2 - sidewall (2 pcs.); 3 - bottom; 4 - groove along the thickness of the partition and a depth of 1/2-1/3 of the thickness of the material

Sand the surfaces and assemble a rectangular box from blanks. Lubricate the ends with carpentry glue and fasten the parts with small carnations.

Saw out a central partition from 5 mm plywood, the width of which should be 1 mm less than the distance between the grooves in the walls of the box. Mark the location of the cutout for the hand, drill the entry hole for the file, and cut the plywood with a jigsaw.

Partition drawing

Partition drawing

Spread the grooves with glue and install the partition in place.

Make two pads for the handle from a block with a section of 20x45 mm, rounding the corners of the blanks with a planer. Prepare holders for hand tools from the rails: in one, cut out recesses for pliers and pliers with a jigsaw, and in the other, drill holes for screwdrivers with a drill. Using glue and screws, fix the parts to the partition by placing them at different heights.

So that the surfaces do not get dirty for a long time, cover the box with varnish.

Toolbox in stool

In this upside down stool, you can move the tool to any place in the house or yard, and put it on its legs, reach for a shelf or hammer a nail where your height is almost not enough.

Using plywood or OSB with a thickness of 10-15 mm, cut out the cover (item 1), longitudinal sides (item 2) and sidewalls (item 3) according to the dimensions indicated on the drawings.

Make a handle and four legs with bevels at the ends at an angle of 15 ° from bars with a section of 40x50 mm.

Assemble the stool by fastening the parts with screws.

Box assembly scheme: 1 - cover; 2 - tsarga; 3 - handle; 4 - leg; 5 - sidewall

Box assembly scheme: 1 - cover; 2 - tsarga; 3 - handle; 4 - leg; 5 - sidewall

Round the edges of the cover and the oblong cut in it, apply a finishing coat.

Box for the young master

If your child enjoys crafting or repairing, make a small box with him for his favorite tools.

Take planed 16mm boards and cut out the pieces according to the drawings. Prepare a round birch stick for the handle.

Drawings of the details of the box: 1 - sidewall; 2 - bottom; 3 - handle; 4 - handle stand; 5 - holder

Drawings of the details of the box: 1 - sidewall; 2 - bottom; 3 - handle; 4 - handle stand; 5 - holder

Draw lines parallel to the edges on the sidewalls corresponding to the positions of the handle posts, drill through holes for the screws between them.

Remove the burrs with sandpaper and proceed to assemble the box. Connect the bottom and sides with glue and screws, then install the handle stand along the marking lines.

Now replace the second post while inserting the handle into the blind holes. Screw on the screwdriver holders.

Color the box in the color your child chooses.

Wooden box with lid

The necessary set of tools varies depending on the hobby or profession, respectively, and the internal structure of the box may be different. The next tool carrying option is suitable for any equipment, it is distinguished by its solidity and reliability.

Use light wood for the box: pine, linden or poplar. Optimal Thickness planed boards - 12 mm, thinner ones are more difficult to fasten, and thick ones will increase the weight of the structure.

Required accessories:

- Pen.

- Corners - 8 pcs.

- Latch — 2 pcs.

- Loop - 2 pcs.

Mark the lumber according to the drawings and cut the blanks.

Cutting blanks for the box

Cutting blanks for the box

Table. Parts list

Make sure the cutting is correct by folding the box out of the blanks. Sand down all the details one by one. sandpaper No. 220 and label them. Assemble the bottom and lid of the drawer using clamps, corner clamps, or mounting brackets to secure the blanks. Lubricate both joining surfaces with wood glue.

Drill guide holes for the screws and countersink for the hats, and after fastening the parts, wipe off excess glue with a rag.

Fasten the blanks of the body of the portable part. Replace the dividing partitions by screwing them on the sides and bottom with screws.

Screw the carrying handle in the middle.

Install support rails inside the drawer at a distance of 30 mm from the top.

Clean out pencil marks and burrs near the screws with a fine sandpaper, blow dust off the surface.

Cover the box with a layer of polyurethane varnish, after drying, remove the raised pile with a “zero” and repeat the finish.

Align the hinges with the gap between the body and the lid of the box. Mark and make pilot holes for screws 10 mm deep, fasten the hinges.

Screw on the corner pieces using small screws.

Install the handle and latches on the lid.

Fill the finished box with the tool.

If desired, place containers with dividers or cassettes for storing small items in the large compartment of the drawer.

If you decide to add partitions inside the box, make them removable so that you can change the free space for a new tool.

Every man in the house (apartment) must have a screwdriver, a hammer and at least a handful of different nails. If this is a master with "golden" hands, then you need to have a whole set various tools for which you need a convenient box.

DIY tool box

Many tools (hammer or hacksaw) cannot always be placed in standard tool storage and carrying facilities. Therefore, craftsmen prefer to make with my own hands capacity right size. Consider the stages of work, how to make a tool box.

Material selection

Can be used: metal or plywood. But wood is considered a classic, which has long been the basis of carpentry. So it's easier to do wooden box for tools.

Type of shell

You should think in advance and measure where the chest doors and handle options will be located. The design can be open or closed to accommodate large items. It can be a large box with cells or a designer piece of art.

Interior decoration

The model can be simple for storing various little things or multifunctional: a separate row with holes for various screwdrivers, pencils, glue, pliers, etc.

Drawers with several floors are convenient, they can be inserted into each other or pulled out. The main thing is to achieve maximum order in the arrangement of parts, so that there are nails, screws, tape measure, power tools, etc. separately.

In the manufacture of a particular model, it is necessary to take into account the operating conditions:

- storage location (apartment, basement or garage);

- humidity level;

- temperature;

- frequency of use of devices and devices ( professional activity or home).

Tool box designs

Before buying a compact model for different tools, we list the types of designs:

- The boxes are made of solid durable materials, often rectangular. There are a couple of drawers on the side. Hinged or removable lid with lock. The model is convenient for constant movement.

- A set of boxes is a set of open trays of different sizes that are convenient for the home.

- The case is a compact, durable suitcase, conveniently wide opening, and a handle on the side is a must. Large tools will not fit.

- The organizer is a low container with many cells. Maybe a case or bedside table with cells for small things.

- The tray looks like an open box with recesses, no handle. Not convenient for transportation.

- The bag looks like a sports bag, handles. The model is roomy, but not reliable, and the fabric lets moisture through.

- The backpack is adapted for storing tools, but it is inconvenient to get them.

- The container is a compact closed product with many drawers and sections, some are removable. Transformers are especially convenient.

- The trolley is used in factories, it is a large container on wheels with a comfortable handle. Many sections, easy to move over short distances.

Tool clothes

- This is a vest with pockets where various tools are distributed.

- A belt bag is an indispensable thing when repairing.

- Apron with ties at the neck and belt with pockets.

- Folded storage pouch.

Types of Best Tool Boxes

An important role is played by the material from which the structures for storing and moving various tools are made:

Tool box on wheels

Models made of plastic (metal) with a vertical body with 2 wheels. Convenient handle and lock, the model contains many sections. The only negative is the high price.

Aluminum

Boxes made of aluminum are the most durable and reliable. Popular models of metal boxes for any tools:

- Fit 65610 - aluminum body, equipped with a handle, mobile partitions inside, weight 1.5 kg.

- Dexter is the most compact drawer for small parts.

- Wilton 16910U is a handy aluminum case with steel hinges. Weighs 3 kg, has many pockets on the lid.

car boxes

- Bawer is a universal model, mounted conveniently under the car frame. The car box is strong and reliable, made of galvanized steel, but the weight is 12.4 kg.

- KAMAZ - simple robust design from metal for long-term storage of any inventory.

- I-580 is the most convenient model made of polyvinyl chloride (high-impact plastic with 3 types of steel). Weight 35 kg, capacity 90 l, reliable locks, perfectly protected from moisture.

Large capacities

- STANLEY Mobile Job Chest is the most practical, dimensions: 962:600:600 mm, made of thick plastic, amazing capacity.

- StanleyFatMax with the most thoughtful functionality. Lid with latches, inside 3 sections, there is a lower section for large tools. Handles on the sides, wheels make it a popular model.

- Peli 0450 - considered the most mobile: 3 handles and wheels with reverse. Sealed impact-resistant stainless steel case body, volumetric sections, containers are easy to insert into each other. The only negative is the large weight and volume.

For balcony

Inexpensive models are suitable for storage on the balcony:

- Fit - the case is ideal for small parts, you can change the size of the cells. Sturdy plastic latch.

- Lot-3 - affordable, inexpensive and compact, there is a pen, colored trays.

- MosPromTara for the home, no sections, but there is a lid.

Organizers are more convenient in use for ease of transfer to any place.

With combination lock

- Brauberg - used to transport valuables. A shockproof case made of steel 8 mm and plastic is made, inside 6 cells.

- Hairway - with the greatest protection (metal with plastic), locks with a code on 2 sides of the model, dimensions: 420x215x330 mm.

metal

- Intertool is a popular drawer with 5 compartments, a secure lock and a comfortable handle.

- STANLEY Expert Cantilever is practical and convenient, 5 folding compartments, protection against finger injuries, comfortable handle, but heavy.

Plastic tool boxes

- StanleyClassic made of impact-resistant plastic, comfortable design.

- Tayg is made with amazing rationality, everything is compactly placed.

Professional

Stanley is reliable and indispensable, corrosion protection, handles are equipped with soft inserts. Removable castings inside, special compartment for drills, etc.

Bosh LT-BOXX - simple in execution, but reliable. The strength of the product provides acrylonitrile butadienstrol.

Photos of the best tool boxes

The idea to make a joiner's box was a long time ago, but all hands did not reach. As soon as the time was right, he got down to business. The choice of materials was based on what was at hand. Side panels in pine, handle in ash, side slats in beech, bottom in plywood (pine). Beech planks in their past were 45 cm parquet. Drawer height 30 cm. Internal dimension 14 cm / 40 . At the bottom of the box was a compartment for chisels and jigsaw files. Seats for drills and pens for wood were also made. When assembling, I used D3 wood glue, screws and small nails. In general, it turned out to be a very compact and functional carpentry box in which everything you need is at hand.

I started by drawing a blank for the side wall of the box.

Rails selected for

Trying on the received blanks

Gluing drawer for chisels

Glued side stops for chisels

Installation of side rails

This article is about how to make a wooden tool box. If you have a lot of tools and want to keep them organized, the best thing you can do is to create a simple wooden box. From our experience, we find them very useful as they are lightweight, durable and provide plenty of storage space for tools. Don't forget that you can adjust the size and design to suit your needs.

The main components of the tool box are made from 20mm boards, as they have a beautiful appearance, and very durable. In addition, we recommend that you glue the joints and fasten everything with self-cuts. Try to screw in the screws as symmetrically as possible.

Upon completion of the assembly, it will be necessary to sand the entire surface of the box. Make sure all edges are smooth. Otherwise, you may injure your hands on sharp edges. Also, be sure to check that the heads of all screws are flush with wooden surface. Get rid of dust and chips before painting.

What you need to make a wooden tool box

In order to make a wooden tool box, you will need the following:

materials

Instruments

- protective gloves, goggles;

- ruler, ;

- crayon, tape measure, level, carpenter's pencil;

- and drills.

Adviсe

- Pre-drill holes in wooden components before tightening screws.

- Make a handle out of a cylindrical stick.

Time

- 1 hour

Drawer decoration

Making a simple wooden toolbox is one of those projects that can be done in less than an hour. But it can make your life easier, especially if you work with tools a lot.

Smart Tip: Before joining the parts, add some glue to the joints. Immediately remove excess adhesive with a dry cloth, otherwise it will be difficult to remove after drying.

The first step of the project is markup. As you will see in the next step of the project, we will be using 1x8 boards to make the tool box. Therefore, you should use a carpenter's pencil and square ruler to mark lines on wooden boards.

In order to get accurate cuts, we recommend using a jigsaw or a good circular saw. Make sure the saw has smooth teeth or it may tear off the edges.

Smart Tip: Also, check that the blade will pass exactly along the cut line before sawing.

In the picture, all the components needed for the box. A circular saw can make the job easier, as many of the cuts need to be made at an angle.

You must use this blueprint when crafting crate components. Make sure you double check all measurements otherwise the components may not match.

After creating the wood pieces, you need to drill holes around the edges. As you can see in the picture, you need to plank wooden block to prevent damage to the surface. Drill three holes on the bottom and two holes on the sides.

Smart Tip: If you are not experienced in woodworking, you should draw guidelines for pilot lines. Indent from the edges to prevent splitting of the wood.

If the bottom edges are not smooth, you should carefully sand them with 120 grit sandpaper before assembling.

Coat the bottom ends with wood glue to strengthen the connection. Remove excess glue with a dry cloth, otherwise you will waste time cleaning it.

Press the components firmly and leave for half an hour. If you are using good glue, it will well fasten the joints.

Still, screw the self-tapping screws into the drilled holes anyway.

In order to obtain a solid construction, we recommend using self-tapping screws. Work carefully to prevent damage to wooden components.

Smart Tip: Align all parts before twisting. As you can see in the picture, the edges should be even.

After installing all the components together, the tool box should look like the one in the photo below.

Make a handle out of a cylindrical wooden rod. Handle diameter is approximately 20-25 mm.

Smart Tip: Use a ruler to cut the rod to the desired length.

Add some wood glue to both ends of the rod before pushing it back into place. Then drill a hole and screw in the screw. Hold the handle while twisting, otherwise it may move out of place.

Smart Tip: Leave about 15 mm from the top edge to the wooden handle.

Don't forget to smooth the edges of the wooden components with sandpaper.

Smart Tip: Clean the box of dust and chips before painting.

After completely sanding the entire surface of the box with sandpaper.

Smart Tip: Apply multiple coats of paint, varnish, or stain to enhance the look of the wood and protect the materials from rotting.

If you want your box to have the same dimensions as in our article, we clarify that 1 inch equals 2.54 cm.