Homemade car wash. Do-it-yourself high-pressure pump Do-it-yourself high-pressure washer nozzle

Despite the wide range of services, it is not always possible to wash your car at a car wash. Sometimes you do not need to urgently wash the car, you just need to wash the lights and windows or polluted places after parking the car under the trees. Sometimes only a wet rag is enough for this, but sometimes a bucket of water is not enough. Those who have worked with Karcher portable mini sinks know that the water consumption when washing a car is much lower. The secret of the master offers the design of a portable sink, let's call it low pressure. But this washing will allow, in the absence of running water, to bring the self-washing of the car closer to a civilized method and to drastically reduce water consumption.

How to make a homemade karcher for a car

The design of the sink is extremely simple, to create it you will need plastic container with a tight screw cap with a capacity of 4 - 20 liters (canisters for storing gasoline are very suitable), watering gun, a set of quick-release hose connectors (3/4 threaded fitting, two connectors for the diameter of the hose, a 3/4 - 1/2 adapter) , an automotive nipple for tubeless tires and a piece of hose 1.5 - 2.5 meters long. From the tool you need a knife with a sharp end, silicone sealant and a car pump or compressor.

The principle of operation of a mini sink. A hose with a watering gun is connected to the bottom of the water tank. A car nipple - a fungus - is built into the filler neck. We fill the container with water 3/4 - 4/5 of the volume, tighten the lid and pump the container with air. An overpressure is created in the system under the influence of which water will flow out when the trigger of the gun is pressed.

The assembly diagram of a mini sink with careful execution should not cause difficulties

1. With the sharp end of the knife, slowly and carefully form a hole in the lid of the container, slightly smaller than the diameter of the nipple.

2. Insert the nipple from the inside. Tests have shown that the nipple becomes tight and does not need additional sealing.

Hole for nipple Nipple inserted into cap

3. At the bottom, even without protrusions or a seam of the canister, we slowly and carefully make a hole for the coupling.

4. Using a wire from the inside of the canister, we wind the coupling into the hole.

5. We apply silicone sealant to the junction and screw the fitting to the coupling. We are waiting for the sealant to harden.

Sealant applied6. We twist the lid. We are waiting for the sealant to harden. We connect the pump. We plug the fitting with our finger and increase the pressure in the container, if everything is done carefully, the container will keep the pressure.

7. We equip the hose with connectors. We connect one end of the hose to the canister, and the other to the watering gun.

8. Fill the canister 3/4 - 4/5 with water and pump air inside. We do not pump the canister strongly, it expands under pressure (becomes more round). Don't get carried away with increasing pressure. When using large volume canisters, it will be necessary to provide clamps to prevent excessive inflation of the container.

Connectors installed» from the material presented by the author, you will learn how you can make a full-fledged mini-sink yourself high pressure working at the same time from a 12 V screwdriver battery, you can also connect to a car battery through an extension cord with alligator clips.

All motorists are well aware of how the car constantly gets dirty, especially in spring and autumn, in summer after rain. As the saying goes, "I just left the car wash and then bang torrential rain," many have come across this. Every time you don’t run into a car wash, periodically it runs like that in a month, and without that money is needed for spare parts for gasoline, etc.

It is allowed to wash cars only at specially equipped stations if you are in the city, but you still need to look for a way to save your money, and for this reason the author came up with a portable, compact mini-wash. It consists of a high pressure pump, outlet 8 atmospheres, blow gun, flexible hose, a battery from a 12V screwdriver, wires and a housing from an ordinary plastic bucket, you also need a container for taking water (bucket, canister, bottle)

The advantage of this sink: water intake from any container, low consumption, the ability to work autonomously without an electrical outlet, thanks to the battery.

And so, let's take a closer look at what exactly is needed to create a mini pressure washer?

materials

1. high pressure pump 8 atmospheres

2. 12V battery from a screwdriver

3. plastic paint bucket

4. wires

5. switch

6. contacts

7. solder

8. water tank

9. hose

10. jet from the Zhiguli carburetor

11. gum

12. bolts

13. nuts

14. washers

15. crocodiles

Instruments

1. drill with cone drill

2. stationery knife

3. screwdriver

4. soldering iron

5. pliers

Step-by-step instructions for assembling a mini pressure washer with your own hands.

First, we check the operation of the pump (the author ordered it from China), we connect the hoses, there will be 2 of them, that is, one for water intake, and the second for feeding into the gun. We unscrew the blue clamp and put it on the hose.

Now we twist and the whole connection is tight, the hose has nowhere to go.

Connect the hose and secure with a clamp.

Instead of a native nozzle, a jet from a Zhiguli carburetor is screwed in; it fits perfectly on the thread.

Everything is now much smaller in the gun opening, which will contribute to the creation of a strong compact jet.

Such a switch is also inexpensive and can be bought at any specialized store.

The master soldered wires with contacts to the battery of the screwdriver, doing this with the expectation that the solder did not interfere with the connection of the charger and the battery could be recharged.

The wires are fixed with electrical tape.

Also, the wires practically do not interfere and the battery can be freely connected to the screwdriver itself.

And together the circuit is connected through contacts (father + mother).

After that, the master proceeds to assemble all the details of the mini-sink in the body of a plastic bucket, for which he drills 4 holes in the wall of the bucket using a drill with a conical drill.

The pump is wall mounted.

Tightened with 4 bolts and nuts.

At the bottom of the bucket, a mount was also made for installing a screwdriver battery, for which an elastic band and a bolt with a nut were used.

For the extension cord, a mount is also provided, and it is located under the bucket lid.

Then holes are again drilled in the bucket for the gasket and hose connections.

As you remember, there are 2 hoses, one for inlet and one for outlet.

Everything fits compactly in this plastic bucket, the only thing is that the container must be taken separately.

Since I didn’t see the clutch cylinder, I also didn’t understand much in the diagram. Therefore, there were next questions:

– cylinder diameter and piston stroke?;

- the ratio of the lever arms ?, one shoulder if I understood correctly 35 mm, and the second ?;

- the maximum pressure that the compressor develops?

And yet -Lefty, I did not understand about 160 atm and the volume of the sound. The volume should not depend on the initial pressure. It depends on the muzzle pressure or, in other words, on the air flow and on the design of the muffler. Those. or you have a bad percussion mechanism or muffler. If you fill a cylinder at 160 atm, then to what pressure do you fire, what is the energy and number of shots.

HP pump. I'm not a specialist in hydrodynamics.

Therefore, I ask for help so as not to step on the notorious rake.

With best regards, Vladimir

Connecting tube too long - large dead space

It is not advisable to make an outlet on the side (in such a design), see the previous paragraph.

Yes, I would also seal the HP cylinder

The rest can be seen from the picture.

I almost forgot: at the outlet (near the pressure gauge) a bypass valve is required

High pressure tank compressor!? Who knows what?

A couple of months ago I saw one at the market, held it in my hands. The seller asked for about $ 40, did not buy, was greedy to take a "pig in a poke", but now it's gone. The compressor is not large, weighing about 8-10 kg (I don’t remember exactly), two-cylinder, V-shaped arrangement of cylinders different diameter. The drive is brought to the splines of the crankshaft, compactly.

Working pressure 150kg\cm2. Used to start a diesel engine. But, since the equipment is military, then maybe try to squeeze out more? In general, more information is needed:

1 drive power;

2 Rated crankshaft speed;

3 Upgradable?

Regards, Oleg

The compressor is not an AK150, if so, it was also used in the T80 for pumping cylinders up to 150 atm. Design 3 step, one cylinder with 1 degree, the second 2 steps. I'll try to find the exact specifications.

High pressure pump

Do-it-yourself high-pressure pump Since I did not see the clutch cylinder, I also understood little in the diagram. Therefore, the following questions arose: – cylinder diameter and piston stroke?; -

DIY high pressure washer

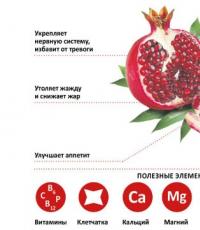

High pressure washer - convenient fixture, which allows you to easily wash the car, as well as other surfaces in everyday life. thanks to the strong pressure of water, such devices are able to clean even heavily soiled surfaces without the use of detergents.

Such devices are usually installed at car washes and cost a lot of money. The Karcher pressure washer deservedly gained popularity, but not everyone can buy it. Therefore, for use at home, you can make a car wash with your own hands. A homemade car wash is a great alternative to professional Karcher devices, which you can assemble yourself from improvised means.

Industrial pressure washer

What you need to make

To make a Karcher pressure washer, you need to find suitable materials. You can use improvised items or purchase new ones in the store. So, to create a minisink you will need:

- Water tank. The container will hold water that is used for washing. The tank should have a capacity of about 5 liters, otherwise you will have to constantly replenish the car wash near the water source. You should not choose too large a container, as the sink will be very heavy. An old plastic canister or bottle can be used as a water reservoir. When choosing a tank, make sure that there are no seams on the bottom of the tank.

- Pistol for irrigation hose. This attribute can be purchased at any store. garden tools. In addition, the gun can be made independently.

- Rubber hose from 0.5 to 4 m long.

- Several hose connectors.

- Sealant.

- Using a simple set of inventory, you can assemble a Karcher type sink. Also homemade car wash will require the use of a set of tools that can be found in any home: a sharp knife, a compressor or a car pump.

Making a pressure washer from a canister

The principle of operation of the device

Do-it-yourself high-pressure washing will work on the principle of conventional car washes. The water in it is supplied through a rubberized hose under high pressure. Air is pumped into the water tank by a car pump, which creates excess pressure in the tank. Water under pressure is supplied to the outside and is supplied when the trigger of the watering gun is pressed. Thanks to the strong pressure of water, with the help of a car wash, you can clean any surface.

In this case, the pump is used exclusively for pumping air into the tank. Replace the constant use of the pump, you can install a pump that allows you to manually raise the pressure. Also, plunger pumps are an alternative to automobile pumps.

Types of high pressure washers

Plunger pumps are modern devices that belong to hydraulic dosing devices. The plunger pump independently mixes water in the selected proportions, detergents and feeds the mixture under high pressure. The disadvantage of installing such a pump is the excessive final weight of the car wash.

How to assemble a car wash with your own hands

Initially, you need to prepare a water tank. To do this, using a sharp knife in the lid of the canister, it is necessary to cut a hole that will be narrower than the nipple in diameter. After that, a nipple is threaded through the inside of the lid.

Advice : If the hole is larger than required, the gaps must be additionally sealed.

Through the nipple in the lid, the pump will pump air into the tank, and water and detergents will also be filled.

Next, you need to prepare a system for connecting the canister to the watering gun. To do this, in the lower part of the canister, you need to cut a hole close in diameter to the coupling. The clutch is attached from the inside of the canister, you can start it with a piece of wire. After threading the hose connector, sealant must be applied around the circumference. A fitting is also attached to the coupling.

Approximate scheme for compiling a homemade pressure washer

After the sealant has dried, you can begin to prepare the sink for work. To do this, plugging the fitting with your finger, you need to pour water into the canister. Also, any detergents (specialized detergents for cars or household chemicals) can be added to the tank. The nipple must be connected to the car pump and gradually pump the canister with air. During this action, you need to ensure that the canister does not inflate too much. If it was decided to install a plunger pump or pump, then they are attached to the fitting using connecting hoses.

After completing these steps, a rubber hose is connected to the fitting, at the end of which a watering gun must be attached.

Setting up a homemade high pressure washer

Advice : You can check the correct assembly by pressing the trigger of the gun. If, as a result, a strong pressure of water began to flow from the gun, then the device was assembled correctly. If this does not happen, then the canister is leaking air and you need to check all connections again and, if necessary, treat them with sealant.

Thus, it is easy to assemble a minisink with your own hands, just follow the proposed instructions and buy a minimum set of equipment. As a result, within an hour, you can make a car wash, which, in terms of the quality of work, does not differ slightly from professional equipment in car dealerships.

How to assemble a car wash with your own hands from improvised means

A list of the necessary equipment and tools for creating a car wash. detailed instructions sink design.

Plunger water pump - distinctive features and applications in everyday life

If you decide to start a car wash business or just decide to keep your personal car in perfect cleanliness without resorting to services, then when designing a car wash with your own hands, you cannot do without the use of high pressure pumps. Most the best option in this case, it is the use of plunger models that provide the necessary pressure in the system and are characterized by high performance and price.

What is a plunger pump. Operating principle

The main element of the pump is a plunger - a long displacer in the form of a cylinder with a small diameter. Unlike the piston type, the seal is placed inside the outer cylinder, in which the plunger moves, in contact with its walls. During the reverse stroke of the plunger, liquid is sucked into the working chamber through the inlet valve, during translational movement, the inlet valve closes and the liquid is pushed out through the outlet valve.

Rice. 1. The device and principle of operation of the plunger pump

Differences between plunger pumps and piston pumps

Many people confuse the plunger and piston type pumps due to the similarity of the principle of operation and design (the displacer moves in the working cylinder). However, there are significant differences that make plunger pumps indispensable devices in many areas.

- The plunger has a cylindrical shape, which makes it possible to process its surface as accurately and with high purity as possible, which cannot be said about the inner surface of the cylinders, the processing of which is technically and technologically difficult. This allows you to fit the plunger as accurately as possible to the geometry of the surface of the working cylinder, which has a positive effect on the output pressure.

- Unlike a piston with a short length of the ejector working surface, the plunger cylinder has an elongated shape, which makes it possible to place a large number of seals along its course and, accordingly, obtain a higher outlet pressure.

- Seals in plunger types are located on inside the working cylinder, which is technologically difficult to process with high purity and accuracy, the plunger in contact with the seals, on the contrary, has a very high class of processing - this factor also makes it possible to obtain very high pressure in plunger pumps.

In modern high-quality plunger pumps, manufacturing accuracy is very high - the working cylinder moves inside the outer one with a gap between the walls of about 2-3 microns, and seals are placed on the outside of the plunger at its inlet and outlet from the cylinder.

- Unlike piston types, the working surface of which is deformed when it comes into contact with liquid at high pressures, in plunger pumps, a rigid and durable working cylinder does not change its shape at high pressures, which makes them indispensable when it is necessary to accurately dose liquids.

Rice. 2 Plunger pump interior

Thanks to their design features plunger pumps allow you to get the outlet pressure 3 times more than piston pumps with the same dimensions of the working chamber.

Application area

Plunger models are devices special purpose, which create very high pressure, so they are practically not used in everyday life. The main areas of their use are the industrial sector, they are used in the following industries:

- In the chemical industry for pumping highly viscous substances and their precise dosing in the manufacture of chemical compounds that do not react with metal.

- For supplying metered amounts of water and other high pressure liquids.

- In the oil and gas industry when drilling wells.

- In the energy industry in steam generators.

- In mechanical engineering in the manufacture of equipment with a hydraulic drive with a working pressure of up to 3000 bar, in the automotive industry in injection systems for diesel engines.

- Plunger water pumps are widely used in car wash service centers.

One non-traditional application for plunger pumps is water jetting and material cutting. At a pressure of about 2000 bar. a jet of water is able to remove paintwork or rust without residue. The technology is widely used in cleaning reinforced concrete structures, sides of ships and runways. The 3500 bar water jet achieves the highest degree of cleanliness of the WJ-1 surfaces according to the international standard.

Rice. 3 Appearance plunger pump

Main characteristics of plunger pumps

Plunger pumps are volumetric views, that is, when the volume of the working chamber increases, the liquid enters the device, and when the volume decreases, it is pushed out.

- Power consumption. The consumed electricity directly depends on the performance and the pressure created, in this respect, plunger models have an advantage over other types due to the high efficiency of more than 90%.

- Performance. It is determined by the volume of the working chamber of the pump, has the widest range from tenths of a liter per minute to ten thousand.

- Operating pressure. The working pressure of plunger types varies widely from hundreds to thousands of bar., The maximum value is about 3500 bar.

- Models differ from each other in the number of plungers.

The operation of the pump is characterized by increased vibrations, which adversely affect its service life and performance characteristics. An engineering solution to this problem was the use of several plungers operating with a phase shift in one unit. The most common are three-plunger models with a displacement of the stroke of the working cylinders of 120 degrees, the maximum number of plungers can reach 6. The implementation of this method is achieved by installing three eccentrics on the engine shaft that control the stroke of the plunger cylinders with a shift of 120 degrees.

Do-it-yourself plunger pump in a car wash device

In everyday life, you can use high-pressure plunger pumps for water when organizing do-it-yourself car washes.

Fig.4 Hydraulic circuit car washes

To do this, you will need the following components:

- High pressure plunger pump for water 100 - 200 bar. and productivity of 15 l./min. It is quite difficult to find electric water pumps with an electric drive, usually an electric motor is connected to them.

- Electric motor 2 - 3 kW. with a maximum speed of about 2000 rpm.

- Reducer and V-belt transmission for connecting the electric motor and pump. It is possible to directly connect the shaft of the pump and the motor with a soft coupling, which can compensate for the difference in the shafts and avoid damage in case of jamming.

- Reinforced rubber or high pressure plastic hoses.

- A gun with a nozzle and a handle that controls the water supply.

- Water tank with feed from the water main and a filter element at the outlet. The need for a separate tank for washing a car is due to the fact that car shampoos are added to it - this cannot be done by directly connecting the pump to the water main.

- For the convenience of working in the system, it is necessary to use the pump power control in tandem with an unloading valve that poisons excess water back into the tank.

Fig. 5 Do-it-yourself car wash accessories

The main elements are mounted on a rigid frame, which is equipped with wheels and a handle for ease of movement.

Plunger pumps are quite expensive devices widely used in industry to create high pressure fluids and accurately dose them. In everyday life, they can be used in systems designed for do-it-yourself vehicle washing.

Do-it-yourself high-pressure plunger pump for washing water

What is a plunger pump. The principle of operation and differences between plunger pumps and piston pumps. Application area. Main characteristics of plunger pumps.

How to make a high pressure washer with your own hands

What is a pressure washer?

Today, you no longer need strength and time to fight dried-on dirt and dust that has clogged into nooks and crannies, because every year new models appear on the market. high pressure washers. These devices are used to wash windows, cars, walls and doors of houses, barbecues and other items that are difficult to clean with a rag or brush. A strong water pressure copes with this task much more efficiently and saves money spent on washing a car in a service, while water consumption is also minimal. Therefore, it is useful for everyone to have such a sink in their arsenal.

The leading companies in the production of high pressure washers are the German companies Bosch, Karcher (hence the second name of the sink - Karcher) and Elitech. The average price of these sinks on the market starts from 10,000 rubles. Inexpensive car washes cannot be used for more than one car per day, and the most expensive models are limited to seven cars.

Washing device

The main component of the sink (or Karcher) is the engine that creates the necessary water pressure. A pump or a motor is suitable (it is not necessary to buy a new one, take a working one from an old car), the motor is built into the sink body and must be connected to a power source. For the sink body (body), choose a durable material, thick plastic or metal. Even if you get a durable case, it's best not to use the sink for more than three hours in a row. This will disable the sink in a short time.

Hose attachments are available to facilitate the cleaning process - brushes of various hardness, soft rollers, standard sprayers. With the purchase of a pair of attachments, you can expand the functions of your sink, using it as an automatic mop or steam cleaner (it is required to equip the sink with a heater).

Internal pressure

The higher the pressure inside the housing, the stronger the jet of water from the hose, which means that the dirt lags behind more easily. Set the pressure carefully, because water can simply break a fragile car part or glass, leave dents. Manufacturers set the pressure at 150-170 bar, but 100 bar is enough to clean the car.

If the contamination cannot be cleaned with a jet of water, purchase a special nozzle for a hose, a turbo cutter. It will help wash tires, wheels, remove dirt accumulated in the cracks. You can use the mini-sink both outside and inside the cabin. If you are using a turbo cutter, you will need 160 bar pressure.

Electric pump

Before purchasing and using a pump in a sink design, read how to choose the right device.

The material of the pump determines the wear resistance. The unfortunate option is a plastic pump, which will soon fail if used for more than 20 minutes at a time. Expensive, but reliable pumps are made of brass, because it does not corrode. These pumps are rarely found in commercial car washes.

How to use the mini sink

To wash worked properly follow these guidelines.

- Be sure to check the performance of the sink before using it, this will save your time and health.

- The filter installed in the car wash should be cleaned and replaced after each use.

- If the washer uses electricity in operation, and the source is unstable, supply it with a battery.

- Do not let children use the sink.

- If repairs are needed, don't hesitate to do so. Replace failed sink components.

- Update your device pads.

- Protect your sink from temperature fluctuations.

How to make a karcher yourself

Although car washes have achieved widespread use, their cost is high. So, if you want to do your own washing, you need:

- canister;

- irrigation hose with a gun;

- pump;

- Union;

- cover for the canister;

- tubeless wheel fungus;

- rubber gasket;

- coupling.

These are the components of the future car wash. Materials that come in handy during the manufacturing process:

First step. The choice of components.

The required volume of the canister depends on you and the purpose for which you use the sink: for passenger car enough five-liter canister. Drivers carry a car wash in their luggage, and therefore choose a case both in terms of volume and dimensions.

The irrigation hose must be strong and flexible, it must not be twisted or broken. Nylon-braided hoses are considered durable. A hose consisting of several layers is more reliable. Don't skimp on this part. There is only one requirement for a pistol: it must be firmly attached to the hose.

The pump can be foot or automatic. The high power of this pump will not be useful to us, so do not buy an expensive one. Using an automatic pump is much more convenient than using a foot pump, since you do not have to constantly drag the pump from place to place and do unnecessary work with your foot. However, the decisive role is played by the cost of the pump, automatic is three times more expensive.

Choose the fitting and the coupling at your discretion, the main thing is that they are in close contact with each other. It is preferable to purchase both the fitting and the coupling from the same material (plastic or metal).

Second phase. Canister preparation.

Drill a hole in the canister that fits your coupling. Insert a coupling with a screwed fitting into this hole. Secure the structure with a sealant so that the coupling does not pop out during operation, and the desired pressure is maintained in the canister.

Third stage. Cover collection.

The lid needs to be strong, solid and suitable for the canister. To prevent air from escaping from the canister, attach a rubber gasket to the bottom of the lid. Then make a hole in it and insert the fungus of a tubeless tire into it.

Fourth stage. Construction collection. Additional functions.

Tighten the canister tightly with a lid, connect the cord from the pump to the fungus, attach the free end of the hose to the hole made in the canister using a fitting. Homemade sink is ready. The principle of operation of such a sink is simple: using a pump, air is pumped into a canister of water (while the canister is not filled with water to the brim). Pressure up to 0.3 bar or higher if your canister can handle it. Under the influence of pressure, water shoots out of the gun when the handle is pressed.

If you will use the sink during the cold season, equip your sink with a special burner for heating water. For these purposes, you will need a more voluminous canister, it will lose mobility, but with the help of hot water the car is cleaned of heavily dried dirt.

Provide a power source for the sink. If the sink runs on fuel (gasoline or diesel fuel), then there will be no problems with moving. When planning an electric car wash, take care of a serviceable and affordable source of electricity. In this case, you are unlikely to be able to freely transport the sink from place to place, but you do not have to spend money on expensive fuel.

Decide in advance for what purpose you use the sink. If you want to clean the windows of a house or the wheels of a car, then a compact, mobile washer on wheels and with a long hose will suit you. When using a sink on an industrial scale, you will not need its ability to move, so it is better to design a stationary sink. It connects directly to the water supply. If necessary, set the automatic water supply to save.

If it is possible to save on water consumption, then it is impossible to save on the purchase of washing components. To prevent the item from becoming dirty after washing, purchase special filters. You do not need an expensive filter that purifies water to a drinking state. The filter is needed to purify water, at least from litter, which will disable the sink.

You can even earn money by designing a pressure washer if you open a car wash. The main thing is that the sink you made works. Using the car wash, you can clean bicycles, mopeds, cars, trucks and their components.

How to make a karcher powered by a cigarette lighter

This sink design is cost-free. The following is an instruction for creating a more complex model:

- windshield washer motor;

- irrigation hose with a gun;

- cigarette lighter (motor power supply), cigarette lighter plug;

- two hoses 3 meters long, one hose must fit freely into the other;

- corrugated hose with a diameter of 25-30 millimeters;

- switch;

- M8 bolt, washer and nut;

- two plastic cans(volume 10 liters);

- 6 screws;

- two-core electric wire 5-7 meters long;

- plastic sleeve;

- power cord;

- car wash brush

First step. Create a hose.

We make a small hole in the bottom of one of the canisters. Inside a thick hose (diameter 10 millimeters or more), a thinner hose (up to 6 millimeters) and a two-wire wire are placed. Then the hoses fastened by us are inserted into the opening of the canister. A plastic sleeve is threaded into the free end of the hose. Further, a thin hose is attached to the washer motor, the wires are also attached to the motor.

Second phase. Creating a canister with a double bottom.

The second canister is cut approximately in the middle in order to subsequently make a second bottom out of it with a shuttle. The motor is fixed on the second bottom of the canister; for this purpose, a home-made clamp is used, which can be made from the remains of a cut canister. To do this, we need an M8 bolt and some sealant.

The wires are also fixed with self-tapping screws and sealant. Then they connect, again using self-tapping screws, the body of the structure: the second bottom and the hinged lid.

Third stage. Completion.

Using the power cord, the wires are connected to the cigarette lighter. A hole is made in the brush for the button, the switch is fixed. The brush itself is mounted on the edge of the hose with a plastic sleeve. Use the attached diagrams in your work to better understand the text.

Do-it-yourself high-pressure washer: photo, device, pressure

How to make a pressure washer with your own hands What is a pressure washer? Today, strength and time are no longer needed to fight dried-on dirt and dust that has clogged into nooks and crannies, because

The high pressure washer is a highly efficient machine used for professional cleaning of vehicles – paintwork, engine compartment, rims, other elements.

The device is necessary to create high pressure, strong water pressure, which ensures the cleaning of surfaces and structures.

Such a tool is used by masters in services, but a do-it-yourself home-made high-pressure car wash will cope with the task just as well.

What parts are required to assemble a car wash?

The device of a mini-sink is a simple process. Work begins with the selection of parts for the subsequent assembly of the structure. The working part must be assembled from high-quality, proven materials. Accessories, with the exception of the pump, do not have to be new. But first check the serviceability to avoid breakdowns.

- The pump or motor that provides the creation of water pressure is the main part. When choosing, attention is paid to performance, the ability to create pressure. For infrequent use, at home, a pressure of 100 bar is sufficient. When installing additional equipment, nozzles require up to 160 bar. Average indicators vary between 100-200 units.

- The electric motor is the power source of the system. At self assembly it is recommended to choose single-phase devices with a potential of 220V. They are safer and more affordable.

- Coupling - necessary to connect the pump and the power plant. It is preferable to have models that can act as a fuse and balance the misalignment of the shafts along the axis.

- Housing, water tank - provides a uniform supply of water masses. Tanks made of durable plastic or metal are used.

- The frame is the basis for the secure fastening of the elements. Often, additional wheels are installed at the bottom for mobility and ease of use.

- Gun with nozzle, hoses - required for water supply. The hose is chosen high-quality, reinforced.

- Nozzles - used to change the nature of the water flow. There are many models that are used to solve specific problems.

It is not worth saving on the quality of parts - this will affect the performance of the device.

In order for a do-it-yourself home-made high-pressure washer to be assembled correctly, other components will be required.

Additional elements:

- filter element - a fine mesh that prevents the ingress of particles of dirt, debris;

- capacitor, single-stage gearbox - optional components, but they make it easier to start, improve the quality of work, productivity;

- – can be used as a pump, base for a car wash, greatly simplifying the assembly;

- performance regulator, unloading valve - parts that ensure safety and efficiency of operation;

- clamps or hydraulic termination - will make the connections airtight;

- elements in contact with water are selected from corrosion-resistant alloys.

After completing the collection of spare parts, you can begin to fasten the elements and install them on the frame. It is important to maintain the possibility of repairing equipment, more often using threaded connections.

In the process of assembling a car wash, there are several important points that determine the safety of further operation and the absence of malfunctions.

The frame is the basis of the whole structure:

- it is planned to manufacture a system with optimal dimensions for which suitable pipes are selected - round, curved;

- in addition to the wheels in the lower part, it is desirable to install clamps;

- handle for easy transport.

Grounding - safety element:

- a three-core wire is selected;

- a plug with a grounding terminal is required;

- socket is grounded.

After preparation, several main stages are carried out:

- Electrical equipment is installed on the frame, including an engine, a pump, and other structural elements.

- A gun with a nozzle is attached, which supplies water after pressing a special button. Such devices are used by professionals, but they are easy to purchase in the store.

- A high-pressure hose is being installed.

After completing the assembly, they connect to the water supply. A 7 m hose is suitable for this.

How to avoid unexpected device breakdowns

When thinking about how to make a car wash with your own hands, it is desirable to ensure optimal operation, preventing the need for subsequent restoration.

Important Points installation usage:

- before starting, all connections, fastenings are checked;

- filter element needs regular cleaning from pollution;

- do not often use the equipment at full power;

- mounting battery protect the device from power surges.

With self-assembly of the device, subsequent restoration, replacement of rubber rings, seals will not cause difficulties.

A car wash is used to remove debris, dirt from a car body and other parts. The foam generator allows you to maximize the quality of cleaning. It's also easy to make your own.

A small number of tools are selected:

- roulette;

- knife;

- Bulgarian;

- wrenches;

- pliers.

Thinking about how to make a foam generator for a car wash with your own hands, you should also choose the right materials and parts for assembly.

Basic moments:

- A pipe is required, at least 50 cm long. It is filled with a polyethylene washcloth for the subsequent formation of foam.

- A filter is installed in the form of a grid to prevent the filler from entering other nodes.

- One end of the pipe must be plugged, a tee must be installed for the subsequent fixing of the foam concentrate tap.

- Using a fitting, they connect the pipe and the hose intended for foam.

- A valve is connected to the other end, providing a flow of compressed air masses.

The characteristics of the foam that will result from the operation of such an installation is determined by the length of the pipe used. Attention requires the density of filling the plane with a washcloth. For filling auto cosmetics, a container that can withstand the pressure exerted by the system is suitable.

The characteristics of the foam that will result from the operation of such an installation is determined by the length of the pipe used. Attention requires the density of filling the plane with a washcloth. For filling auto cosmetics, a container that can withstand the pressure exerted by the system is suitable.

A car wash and a foam generator are useful units that simplify the process of car care. They easily cope with loads in home use, perfectly replacing the factory tool.

Add site to bookmarks

- Kinds

- Choice

- Mounting

- Finishing

- Repair

- Installation

- Device

- Cleaning

How to make your own car wash

Washing a car with your own hands is a tedious and unpleasant task, and it takes a lot of time to do it. This is especially felt in spring and autumn, when there is dirt and slush all around. In order to wash the car yourself and well, you need to change clothes so as not to get dirty yourself. Of course, you can use the services of a stationary paid car wash. But, firstly, there is not always time for this, and secondly, it costs money. You can buy a mini-sink, but the prices for this product are quite high.

The easiest way to do your own washing is to use an air compressor.

Do-it-yourself mini-sink is simple and accessible to everyone, while there is more than one option for creating this mechanism. Having made it yourself and spending a minimum amount of money on the purchase of parts, you will get only pleasure from washing the car.

What materials will be required?

Scheme of a homemade mini-wash.

This mini-sink will work on the basis of a compressor, all the work can be done independently, that is, with your own hands.

You will need very few parts and materials, so creating it will not cost you much. It is very economical to use parts from old equipment that is no longer in use, for example, from a washing machine.

- tire compressor;

- suitable capacity of at least 10 liters, you must consider not only the convenience of washing the car, but also the subsequent ease of storage;

- long hose (you can use the old one from the washing machine);

- short hose (for example, from a sink mixer);

- fitting with a nipple (it is also not necessary to buy a new one, you can use the old one from the camera);

- a brush (perhaps the only thing you have to buy in a store);

- faucet (one that is used to supply water to the washing machine, or any other that seems more convenient for you to use);

- rubber gaskets (FUM tape can also be used for reliable sealing);

- sealant.

First, connect the compressor to the fitting with a hose. A tap is attached to the brush, with which you will regulate the optimal amount of liquid throughput.

Accordingly, the tap is also connected to the hose. After connecting all the parts, you can start using the device.

This is not the only option for creating a mini-sink. you can do it yourself and the automated version, which, of course, is more convenient. Such a home wash can operate from the on-board network of the car, for example, from the cigarette lighter or simply from the electrical network, but only through a rectifier with a 12-volt output.

Back to index

Materials for the manufacture of an automatic mini-sink

The high pressure pump from a car washer is perfect as a compressor for a car wash.

Everything necessary materials you may already have. If not, you can purchase them at the nearest car market or at a specialized auto parts store. An automated car wash is made simple enough that any car enthusiast can decide to make it with their own hands.

Such a car wash can come in handy not only on ordinary days, but also when traveling, when you won’t find paid stationary car washes on the road. Start manufacturing by selecting or purchasing parts, only after purchasing which you can proceed directly to the assembly process.

- Washer motor. Suitable from any car, for example, from the "nine" or "Volga", it does not matter. It does not have to be new, it can be used, but only working.

- Brush on the hose for washing the car.

- Plug "cigarette lighter".

- Hose, 2 pieces, with diameters of 6 and 10 mm, the length of each is at least 3 meters.

- Switch.

- Electric wire with a length of 5 to 6 m, it is recommended to use two-core.

- Bolt brass M8, with a corresponding washer and nut.

- Galvanized self-tapping screws, 6 pieces, d4×12 mm.

- Polyethylene canisters, 2 pieces, or other suitable containers, with a volume of at least 10 liters.

- Sealant.

- Piece of corrugated hose.

Back to index

Home automated mini-washing device

Hydraulic scheme of a car wash.

You will also not need any special knowledge to create such a necessary thing as an automated mini-wash. Only necessary tools, the availability of the necessary parts and the desire to make the process of washing the car with your own hands more enjoyable.

- First you need to prepare canisters, one of them will have to be cut in order to create a “second bottom”, where a shuttle for winding wire and power and a swivel lid will be arranged.

- For cutting, you can use a knife or scissors, according to the thickness of the walls of the canister.

- Ordinary drinking water canisters are ideal for this.

- In the bottom of the whole canister, you need to make a hole corresponding to the diameter of the large hose, i.e. 10 mm, exactly under the inlet of the canister. On the opposite side, you need to make a hole corresponding to the washer.

- The washer is attached with an M8 brass bolt, respectively with a nut and washer, to the outer surface of the bottom of the whole canister approximately in the middle. The motor is fixed with a clamp, which is easy to make from a strip of plastic.

- To put on the hoses, plastic bushings are used. It can even be cases from ordinary felt-tip pens. After fixing, you need to connect the receiving tube from the motor to the bottom of the canister in the hole made in advance, from where water will flow to the motor.

- Wires and a thinner hose are inserted into a larger diameter hose. It is necessary to push it into the inlet of the canister and through the hole made in its bottom. For reliability, the hose is fixed in the hole with a sleeve.

- You need to install a switch or a button on the brush, make a choice of these parts yourself. Choose what seems more convenient to you, because you will do the entire manufacturing process yourself. The button or switch is glued inside the handle.

To decorate it, use a piece of corrugated hose, a diameter of 25 mm is suitable for this. It must be put on the brush handle in advance, that is, before the assembly is made. Naturally, wires are attached to the switch.

The lower ends of the wire must be connected to the washer motor and to the power cord, which, in turn, must be connected to the washer motor. When choosing a power cord, do not forget that it must be exactly 12-volt. A plug from the "cigarette lighter" is attached to the cord.

After the wires are desoldered, the lower part (cut off) of the canister, that is, its “second bottom”, is attached to the main canister with self-tapping screws. Do not forget about the tightness of the joints, be sure to use a sealant, even if it seems to you that everything is normal anyway. In the same way, you need to attach the swivel cover. If all the nuances and smallest details are observed, the assembly will not take you much time.