Homemade CNC machine from printers with your own hands. Homemade cnc milling machine

In order to make a CNC machine from a printer with your own hands, you will need the following materials at hand:

- spare parts from several printers (in particular, a drive and pins);

- drive from the hard drive;

- several sheets of chipboard or plywood, furniture guides;

- controller and driver;

- fastening materials.

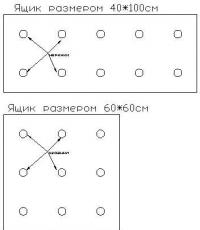

1. The base is a box made of chipboard. You can take ready-made or make your own. We immediately take into account that the internal capacity of the box should contain all the electronic stuffing, so the height of the board is calculated from the height of the board with parts, fastening and stock to the table surface. The assembly of the base and frame from chipboard is carried out by means of self-tapping screws. In this case, all parts must be even and fixed at a right angle.

2. On the cover of the base it is necessary to fix the axis of the machine. There are three of them - x y z. First fix the y axis. For the manufacture of the guide, a furniture skid on ball bearings is used.

It is better to use two guides for two horizontal axes, otherwise the axes will have significant play. For the vertical axis, the role of the guide is played by the remains of the hard drive, that part of it where the laser moved.

The stem from the printer is used as the lead screw. In this case, for the horizontal x and y axes, 8mm threaded screws are made. For the vertical z-axis, a 6mm threaded screw was used. As stepper motor drives from old printers are used. One drive for each axle.

3. The stud is attached to the plane by means of metal corner.

The motor shaft is connected to the stud through a flexible coupling. All three axles are attached to the base through a chipboard frame. In this design, the milling cutter will move only in the vertical plane, and the movement of the part is carried out due to the horizontal movement of the platform.

4. The electronic unit consists of a controller and a driver. The controller is made on Soviet K155TM7 microcircuits, for this case three pieces were used.

From each microcircuit, wires go to the driver of each of the three motors. The driver is made on a transistor. The buildup uses KT 315, transistors KT 814, KT 815. From these transistors, an electrical signal is fed to the winding of the electric drive.

At normal operating voltage, motors may overheat due to lack of busbars in the electronics. To prevent this, a computer cooler must be used for each engine.

Video: a simple do-it-yourself CNC machine for beginners.

Electronic stuffing

There are two options here:

- You arm yourself with a soldering iron, flux, solder, a magnifying glass, and understand the chips from the printer. Locate printer control boards 12F675 and LV1745. Work with them by creating a cnc control board. You will need to attach them to the back of the CNC machine, under the power supply (we also take it from the long-suffering printer).

- Use the factory CNC machine controller. Offhand - a five-axis cnc controller. Homemade electronics are wonderful, but the Chinese are heavily dumping prices. So with a light click of the mouse we order the cnc from them, because in Russia you can’t buy such a cnc device. CNC controller 5 Axis CNC Breakout Board allows you to connect 3 inputs of end motors, a shutdown button, automated control of a dremel and as many as 5 drivers for controlling a stepper motor of a homemade machine.

This cnc is powered by a USB cable. In a home-made version of the CNC, you need to power the control board based on the printer chips from the power supply of the CNC machine.

A stepper motor for a homemade CNC machine will have to be selected with a power of up to 35 volts. At other powers, the cnc controller runs the risk of burning out.

Remove the power supply from the printer. Connect the wiring between the power supply, the on/off switch, the cnc controller and the dremel.

Connect the cable from the laptop/PC to the machine control board. Otherwise, how will you load jobs into the machine. By the way, about tasks: download the program Math3 for drawing sketches. For non-professionals industrial design CorelDraw will do.

You can cut plywood (up to 15 mm), textolite up to 3 mm, plastic, wood with a homemade CNC machine. Products will turn out no more than 30-32 cm in length.

The aim of this project is to create a desktop CNC machine. It was possible to buy a ready-made machine, but its price and dimensions did not suit me, and I decided to build a CNC machine with the following requirements:

- use of simple tools (you only need drilling machine, band saw and hand tools)

- low cost (I was looking for low cost, but I still bought items for about $600, you can save a lot by buying items in the appropriate stores)

- small footprint(30"x25")

- Normal working space (10" X, 14" Y, 4" Z)

- high speed cutting (60" per minute)

- a small number of elements (less than 30 unique)

- available elements (all elements can be bought in one hardware and three online stores)

- the possibility of successful processing of plywood

Other people's machines

Here are some photos of other machines that have been assembled according to this article

Photo 1 - Chris and a friend assembled the machine by cutting parts out of 0.5" acrylic using laser cutting. But everyone who has worked with acrylic knows that laser cutting is good, but acrylic does not tolerate drilling, and there are many holes in this project .they did Good work, more information can be found on Chris's blog. I especially liked making a 3D object with 2D cuts.

Photo 2 - Sam McCaskill made a really nice desktop CNC machine. I was impressed that he did not simplify his work and cut out all the elements by hand. I am impressed with this project.

Photo 3 - Angry Monk's used DMF parts cut with a laser cutter and toothed belt driven motors converted to propeller motors.

Photo 4 - Bret Golab's assembled the machine and set it up to work with Linux CNC (I also tried to do this, but I couldn't because of the difficulty). If you are interested in his settings, you can contact him. He did a great job!

I'm afraid I don't have enough experience and knowledge to explain the basics of CNC, but the CNCZone.com forum has an extensive section on homemade machines, which helped me a lot.

Cutter: Dremel or Dremel Type Tool

Axes options:

X axis

Travel Distance: 14"

Speed: 60"/min

Acceleration: 1"/s2

Resolution: 1/2000"

Pulses per inch: 2001

Y-axis

Travel Distance: 10"

Drive: Toothed belt drive

Speed: 60"/min

Acceleration: 1"/s2

Resolution: 1/2000"

Pulses per inch: 2001

Z-axis (up-down)

Travel Distance: 4"

Drive: Screw

Acceleration: .2"/s2

Speed: 12"/min

Resolution: 1/8000"

Pulses per inch: 8000

Required Tools

I aimed to use popular tools that can be purchased at a regular craft store.

Power tool:

- band saw or jigsaw

- drilling machine (drills 1/4", 5/16", 7/16", 5/8", 7/8", 8mm (about 5/16")), also called Q

- a printer

- Dremel or similar tool (to be installed in the finished machine).

Hand tool:

- rubber hammer (for planting elements in place)

- hexagons (5/64", 1/16")

- screwdriver

- glue stick or spray glue

- Adjustable wrench (or socket wrench with ratchet and 7/16" socket)

Necessary materials

The attached PDF file (CNC-Part-Summary.pdf) provides all costs and information about each item. Only summarized information is provided here.

Sheets---$20

- A piece of 48" x 48" 1/2" MDF (any 1/2" thickness sheet will do. I plan to use UHMW in the next version of the machine, but now it is too expensive)

- A piece of 5"x5" 3/4" MDF (this piece is used as a spacer so you can use any 3/4" piece of material)

Motors and controllers --- $255

-A whole article can be written about the choice of controllers and motors. In short, you need a controller capable of controlling three motors and motors with about 100 oz/in torque. I bought motors and a ready-made controller and everything worked well.

Hardware --- $275

-I bought these items in three stores. I got the simple parts from the hardware store, the specialized drivers I got from McMaster Carr (http://www.mcmaster.com), and the bearings, which I need a lot, I bought from an online retailer for $40 for 100 pieces (it's quite a bargain). , many bearings remain for other projects).

Software --- (Free)

-You need a program to draw your design (I use CorelDraw) and I'm currently using a trial version of Mach3, but I have plans to switch to LinuxCNC (an open source machine controller using Linux)

Head Unit --- (Optional)

-I installed Dremel on my machine, but if you are interested in 3D printing (like RepRap) you can install your device.

Printing templates

I had some experience with a jigsaw, so I decided to glue on the templates. It is necessary to print PDF files with templates placed on the sheet, stick the sheet on the material and cut out the details.

File name and material:

All: CNC-Cut-Summary.pdf

0.5" MDF (35 8.5"x11" template sheets): CNC-0.5MDF-CutLayout-(Rev3).pdf

0.75" MDF: CNC-0.75MDF-CutLayout-(Rev2).pdf

0.75" aluminum tube: CNC-0.75Alum-CutLayout-(Rev3).pdf

0.5"MDF (1 48"x48" pattern sheet): CNC-(One 48x48 Page) 05-MDF-CutPattern.pdf

Note: I am attaching CorelDraw drawings in original format (CNC-CorelDrawFormat-CutPatterns (Rev2) ZIP) for those who would like to change something.

Note: There are two options for MDF 0.5". MDF-CutPattern.pdf) with one 48"x48" sheet for printing on a large format printer.

Step by step:

1. Download three PDF templates.

2. Open each file in Adobe Reader

3. Open the print window

4. (IMPORTANT) Disable Page Scaling.

5. Check that the file has not been scaled by accident. The first time I did not do this, and printed everything at a scale of 90%, as described below.

Gluing and cutting elements

Glue the printed templates on the MDF and on the aluminum pipe. Next, just cut out the part along the contour.

As mentioned above, I accidentally printed the templates at 90% scale, and did not notice this until I started cutting. Unfortunately, I did not understand this until this stage. I was left with 90% scale templates and moving across the country I got access to a full size CNC. I could not resist and cut out the elements with this machine, but I could not drill them from the back. That is why all the elements in the photos are without template pieces.

drilling

I didn't count exactly how many, but this project uses a lot of holes. The holes that are drilled on the ends are especially important, but take the time to make them, and you will rarely need to use a rubber hammer.

Places with holes in the lining on top of each other is an attempt to make grooves. Perhaps you have a CNC machine that can do this better.

If you have reached this step, then I congratulate you! Looking at a bunch of elements, it's quite hard to imagine how to assemble the machine, so I tried to make detailed instructions similar to instructions for LEGO. (attached PDF CNC-Assembly-Instructions.pdf). Looks pretty interesting step by step photos assemblies.

Ready!

The machine is ready! I hope you made and run it. I hope that the article does not miss important details and points. Here is a video that shows the machine cutting a pattern on pink foam.

Thanks to the full-scale introduction of computer technology and automation systems, modern woodworking machines operate according to pre-set programs, which ensures the highest quality of wood processing. Used in specialized woodworking factories and large sawmills, CNC machines make it easy to cut and process wood, while it is possible to make appropriate changes to the operation of such equipment. This ensures the greatest possible versatility in the use of such woodworking machines.

If you wish, you can independently create such CNC machines that will provide complete wood processing with excellent quality of work performed. We will tell you in more detail about how to make a homemade CNC machine with your own hands.

Despite the apparent complexity of the design of such equipment, it will not be difficult to assemble it yourself. Today on sale you can find ready-made kits for the manufacture of such CNC machines, which allows you to minimize your costs, while it is possible to manufacture the necessary CNC milling machine with 3d, which will perform a full range of work with lumber.

Such equipment is versatile in use, which has a positive impact on its demand and popularity in the market. Such devices can be used to work with the following materials:

- Wood.

- Plastic.

- Composites and polymers.

- Thin metal.

- Rubber.

- Other materials.

The most popular CNC machines today, which are fully controlled by automation and provide maximum precision in wood processing. With the help of such woodworking machines you can do the following:

- Sawing a tree.

- Cut plywood.

- Perform precise grinding.

- Perform complex three-dimensional and figured sawing of wood.

- Produce various building materials from wood.

In each specific case, depending on the functionality of such a device, its execution scheme and the components used will vary. That is why you must first decide with functionality such equipment and, depending on this, choose one or another type and scheme for the independent manufacture of a CNC machine.

Hardware Benefits

If we talk about the advantages of manufactured do-it-yourself CNC machines, we note the following:

- Efficiency at work.

- Versatility of use.

- Possibility of simplified reconfiguration of equipment.

- Reliability.

- Affordable cost.

Assembly instructions

offer you enough simple instructions on assembling a CNC milling machine, which will allow you to independently make such equipment for woodworking. This scheme implies the use of ready-made sets of components, which include specially selected elements for the manufacture of such equipment. However, nothing prevents you from finding or manufacturing all the components yourself, and subsequently you will not only be able to save a lot, but also make a machine that will fully meet your requirements.

offer you enough simple instructions on assembling a CNC milling machine, which will allow you to independently make such equipment for woodworking. This scheme implies the use of ready-made sets of components, which include specially selected elements for the manufacture of such equipment. However, nothing prevents you from finding or manufacturing all the components yourself, and subsequently you will not only be able to save a lot, but also make a machine that will fully meet your requirements.

Subsequently, it will be possible to easily connect a computer or a control unit with software to the completed mechanism, which allows you to completely set the trajectory of the milling working head. At the same time, we note that if you use a carriage from an old filter, then you can use such a CNC machine only for processing wood, plastic or thin sheet metal.

If you need a CNC machine capable of performing full-fledged milling of workpieces from various materials, then a powerful stepper motor must be responsible for moving the working tool used. You can run it from a conventional electric motor or purchase ready-made models of low power.

The use of such engines will avoid the need for a screw drive, which complicates the entire design. However, the characteristics of such homemade equipment and his functionality expand significantly. If for some reason you cannot or do not want to use a powerful stepper motor, then we recommend choosing carriages from printers of powerful top models, which will ensure the maximum possible amplitude of movement of the milling working head.

Scheme and drawings of the machine

The basis of a self-made CNC machine will be the milling mechanism. In the event that you use ready-made kits for the implementation of such equipment, then you can choose a mechanism that will fully correspond to the engine power and subsequent work with wood and other materials.

On the Internet, you can find numerous schemes for the implementation of such milling mechanisms for CNC machines. In each case, the mechanism used will differ depending on the installed motors and carriages. When choosing one or another drawing of such a milling machine, it is necessary to give preference to equipment that combines simplicity of design and at the same time fully meets your requirements.

We collect the CNC machine

First of all, it is necessary to complete the basis of the equipment, to which the milling cutter, carriage and electric motor will subsequently be fixed. Such a base can be made from rectangular beams, to which metal guides are welded or bolted.

The completed base for the machine must be rigid, which is necessary for accurate positioning of the milling head. Experts recommend connecting all metal elements such a supporting structure with screws, which allows not only to provide the necessary strength, but also to easily upgrade your machines in the future.

In the completed CNC machine, a mechanism must be provided that allows you to move the working tool in a vertical plane. We can recommend using a screw gear for such vertical movement of the tool, the rotation from which is transmitted using a toothed belt.

In the completed CNC machine, a mechanism must be provided that allows you to move the working tool in a vertical plane. We can recommend using a screw gear for such vertical movement of the tool, the rotation from which is transmitted using a toothed belt.

The vertical axis that every self-made CNC machine will need can be made from an aluminum plate. The dimensions of such a vertical axis should be exactly adjusted to the overall dimensions of the device you are assembling.

Having manufactured or purchased all the components for such equipment, you can begin to assemble the machine. You need to mount two stepper motors that are attached to the base behind its vertical axis. The first electric motor is responsible for moving the head in a horizontal plane, while the second ensures the movement of the cutter is already vertical. The components and assemblies used are mounted, while the quality of their fixation should be given due attention.

During the operation of such equipment, it has an increased load with vibration, and with poor-quality fastening, problems with the positioning accuracy of the heads may soon begin. All moving parts and working milling heads must be driven exclusively by belt drives.

Choice of stepper motors

Most models of self-made CNC machines are equipped with stepper motors that allow you to move the working tool in three planes. Depending on the design, such equipment can be equipped with two or three stepper motors, as well as additionally assembled with electric motors from computer printers.

When choosing the stepper motors to be used, it is necessary to pay attention to the number of control channels. Best Models have five control channels, which increases the functionality of the manufactured mini-machine. Also, when choosing specific models of such motors, you should familiarize yourself with their specifications and clarify by how many degrees the head position on the coordinate table is changed in one step of the motor. Positioning accuracy will directly depend on this characteristic. cutting tool.

Electronic filling of equipment

Today on sale you can find various ready-made microcircuits for controlling the operation of sustainer engines. It will also not be difficult to find the appropriate software that will send control signals to the motors, and, accordingly, they will, by changing their position, lower and raise the working tool.

Today on sale you can find various ready-made microcircuits for controlling the operation of sustainer engines. It will also not be difficult to find the appropriate software that will send control signals to the motors, and, accordingly, they will, by changing their position, lower and raise the working tool.

An important point in choosing The software is that it must necessarily support the drivers for the arduino controllers installed on your mini-machine. Connecting the control board directly to a homemade CNC machine is via the LPT or CNC port.

The easiest way is to order such electronic equipment for a CNC machine directly from Chinese auctions and websites. There you can easily find both ready-made sets for machine tools and separately used electrical equipment. The cost of such chips, software and controllers will be at an affordable level.

Do-it-yourself CNC milling machine is a versatile equipment that allows you to significantly simplify and automate the work of processing lumber, plastic, thin metal, etc. If you have the appropriate work experience, you can independently make such a CNC machine that will provide the necessary accuracy and high performance. You just need to find a high-quality scheme for the execution of such equipment and purchase ready-made sets of components, select the main engines and automation used.

To make a three-dimensional drawing on wooden surface factory ones are used. It is difficult to make a similar mini-model with your own hands at home, but it is possible with a detailed study of the design. To do this, you need to understand the specifics, choose the right components and configure them.

The principle of operation of the milling machine

Modern woodworking equipment with a numerical control unit is designed to form a complex pattern on wood. The design must contain a mechanical electronic part. In combination, they will automate the work process as much as possible.

To make a desktop mini wood router with your own hands, you should familiarize yourself with the main components. The cutting element is a cutter, which is installed in a spindle located on the motor shaft. This design is attached to the frame. It can move along two coordinate axes - x; y. To fix the workpiece, it is necessary to make a support table.

The electronic control unit is connected to the stepper motors. They provide displacement of the carriage relative to the part. Using this technology, you can make 3D drawings on a wooden surface.

The sequence of operation of mini-equipment with CNC, which you can make yourself.

- Writing a program according to which the sequence of movements of the cutting part will be performed. To do this, it is best to use special software systems designed for adaptation in home-made models.

- Setting the workpiece on the table.

- Program output to the CNC.

- Turning on equipment, monitoring the implementation of automatic actions.

To achieve maximum automation of work in 3D mode, you will need to correctly draw up a diagram and select the appropriate components. Experts recommend studying factory models before making a mini.

To create complex patterns and patterns on a wooden surface, you will need several types of cutters. Some of them you can do yourself, but for fine workmanship should be purchased from the factory.

Scheme of a homemade milling machine with numerical control

The most difficult stage is the choice of the optimal manufacturing scheme. It depends on the dimensions of the workpiece and the degree of its processing. For home use it is desirable to make a do-it-yourself desktop mini CNC milling machine that will have the optimal number of functions.

The best option is the manufacture of two carriages that will move along the x coordinate axes; y. It is best to use ground steel bars as a base. Carriages will be mounted on them. To create a transmission, stepper motors and screws with rolling bearings are needed.

For maximum automation of the process in a do-it-yourself wood construction, it is necessary to think over the electronic part in detail. Conventionally, it consists of the following components:

- power unit. It is necessary to supply electricity to stepper motors and the controller chip. Often use the model 12v 3A;

- controller. It is designed to give commands to electric motors. For the operation of a do-it-yourself mini CNC milling machine, a simple circuit is enough to control the functioning of three motors;

- driver. It is also an element of regulation of the operation of the moving part of the structure.

The advantage of this complex is the ability to import executable files of the most common formats. Using a special application, you can create a three-dimensional drawing of the part for preliminary analysis. Stepper motors will run at a certain stroke rate. But for this you need to make technical specifications to the control program.

Choice of accessories for CNC milling machine

The next step is to select components for assembling homemade equipment. The best option is to use improvised means. As a basis for desktop models of a 3D machine, you can use wood, aluminum or plexiglass.

For the correct operation of the entire complex, it is necessary to develop the design of calipers. During their movement, there should be no vibrations, this can lead to inaccurate milling. Therefore, before assembly, all components are checked for compatibility with each other.

- guides. Polished steel bars with a diameter of 12 mm are used. The length for the x-axis is 200mm, for the y-axis it is 90mm;

- caliper. Textolite is the best option. The usual size of the platform is 25*100*45 mm;

- stepper motors. Experts recommend using models from a 24v, 5A printer. Unlike disk drives, they have more power;

- cutter block. It can also be made from textolite. The configuration directly depends on the available tool.

The power supply is best assembled from the factory. At self-manufacturing errors are possible, which subsequently affect the operation of all equipment.

The procedure for manufacturing a CNC milling machine

After selecting all the components, you can make a desktop mini milling machine yourself with your own hands. All elements are preliminarily checked again, their dimensions and quality are checked.

To fix the elements of the equipment, it is necessary to use special fasteners. Their configuration and shape depend on the chosen scheme.

The procedure for assembling desktop mini CNC equipment for wood with a 3D processing function.

- Installation of caliper guides, their fixation on the side parts of the structure. These blocks are not installed on the base yet.

- Lapping of calipers. They must be moved along the guides until a smooth ride is obtained.

- Tightening the bolts to fix the calipers.

- Attaching components to the base of the equipment.

- Installation of lead screws together with couplings.

- Installation of drive motors. They are attached to the coupling screws.

The electronic part is located in a separate block. This helps to reduce the likelihood of malfunction during the operation of the router. Also important point is the choice of work surface for the installation of equipment. It must be level, since the level adjustment bolts are not provided in the design.

After that, you can start trial tests. It is recommended to set up a simple wood milling program first. During operation, it is necessary to check each cutter pass - the depth and width of processing, especially in the 3D mode.

The video shows an example of how to assemble a large do-it-yourself CNC milling machine:

Examples of drawings and homemade designs

The article describes a homemade CNC machine. Main advantage this option machine is a simple method of connecting stepper motors to a computer via the LPT port.

Mechanical

Bed The bed of our machine is made of plastic 11-12 mm thick. The material is not critical, aluminum can be used, organic glass plywood and any other available material. The main parts of the frame are attached using self-tapping screws, if desired, you can additionally decorate the attachment points with glue, if you use wood, you can use PVA glue.

Calipers and guides As guides, steel bars with a diameter of 12mm, length 200mm (on the Z axis 90mm), two pieces per axis, were used. Calipers are made of textolite with dimensions 25X100X45. The textolite has three through holes, two of them for guides and one for a nut. The guide parts are fixed with M6 screws. Supports X and Y in the upper part have 4 threaded holes for fixing the table and the Z-axis assembly.

Caliper Z The guides of the Z axis are attached to the caliper X through a steel plate, which is a transitional one, the dimensions of the plate are 45x100x4.

Stepper motors are mounted on fasteners, which can be made of sheet steel with a thickness of 2-3mm. The screw must be connected to the axis of the stepper motor using a flexible shaft, which can be used as a rubber hose. When using a rigid shaft, the system will not work accurately. The nut is made of brass, which is glued into the caliper.

Assembly Assembling a homemade CNC machine is carried out in the following sequence:

- First you need to install all the guide components in the calipers and screw them to the sidewalls, which were not initially installed on the base.

- We move the caliper along the guides until we achieve a smooth ride.

- We tighten the bolts, fixing the guide parts.

- We attach a caliper, a guide assembly and a sidewall to the base, we use self-tapping screws for fastening.

- We assemble the Z assembly and, together with the adapter plate, attach it to the X caliper.

- Next, install the lead screws along with the couplings.

- We install stepper motors, connecting the motor rotor and the screw with a coupling. We pay strict attention to the fact that the lead screws rotate smoothly.

Recommendations for assembling the machine: Nuts can also be made of cast iron, you should not use other materials, screws can be bought at any hardware store and cut to fit your needs. When using screws with M6x1 thread, the length of the nut will be 10 mm.

Machine drawings.rar

We turn to the second part of the assembly of the CNC machine with our own hands, namely to electronics.

Electronics

Power supply unit A 12V 3A unit was used as a power source. The unit is designed to power stepper motors. Another voltage source at 5V and with a current of 0.3A was used to power the controller microcircuits. The power supply depends on the power of the stepper motors.

We present the calculation of the power supply. The calculation is simple - 3x2x1 \u003d 6A, where 3 is the number of stepper motors used, 2 is the number of powered windings, 1 is the current in Amperes.

Control Controller The control controller was assembled on only 3 chips of the 555TM7 series. The controller does not require firmware and has a fairly simple circuit diagram, thanks to this, this CNC machine can be made by a person who is not particularly versed in electronics.

Description and pin assignment of the LPT port connector.

| Pin. | Name | Direction | Description |

| 1 | STROBE | input and output | Set by PC after completion of each data transfer |

| 2..9 | DO-D7 | output | Output |

| 10 | ASC | input | Set to "0" by an external device after receiving a byte |

| 11 | BUSY | input | The device indicates that it is busy by setting this line to "1" |

| 12 | paper out | input | For printers |

| 13 | Select | input | The device indicates that it is ready by setting this line to "1" |

| 14 | Autofeed | ||

| 15 | error | input | Indicates an error |

| 16 | Initialize | input and output | |

| 17 | Select In | input and output | |

| 18..25 | Ground GND | GND | common wire |

For the experiment, a stepper motor from an old 5.25-inch was used. In the scheme, 7 bits are not used. 3 engines used. You can hang a key on it to turn on the main engine (cutter or drill).

Driver for stepper motors To control a stepper motor, a driver is used, which is an amplifier with 4 channels. The design is implemented on only 4 transistors of the KT917 type.

You can also use serial microcircuits, for example - ULN 2004 (9 keys) with a current of 0.5-0.6A.

The vri-cnc program is used for control. A detailed description and instructions for using the program can be found on the official website.

Having assembled this CNC machine with your own hands, you will become the owner of a machine capable of machining (drilling, milling) plastics. Steel engraving. Also, a home-made CNC machine can be used as a plotter, you can draw and drill on it. printed circuit boards.

Based on materials from the site: vri-cnc.ru

all-he.ru

Cnc do-it-yourself drawings

Knowing that a CNC milling machine is a complex technical and electronic device, many craftsmen think that it is simply impossible to make it with their own hands. However, this opinion is erroneous: it is possible to make such equipment on your own, but for this you need to have not only its detailed drawing, but also a set of necessary tools and relevant components.

Processing of duralumin blanks on a homemade desktop milling machine

When deciding to make a homemade CNC milling machine, keep in mind that this can take a significant amount of time. In addition, certain financial costs will be required. However, not being afraid of such difficulties and having the right approach to solving all issues, you can become the owner of affordable, efficient and productive equipment that allows you to process workpieces from various materials with a high degree of accuracy.

To make a milling machine equipped with a CNC system, you can use two options: buy a ready-made kit, from which such equipment is assembled from specially selected elements, or find all the components and assemble a device with your own hands that fully meets all your requirements.

Instructions for assembling a homemade CNC milling machine

Below in the photo you can see the with my own hands CNC milling machine, which comes with detailed instructions for manufacturing and assembly, indicating the materials and components used, accurate “patterns” of machine parts and approximate costs. The only downside is the instructions English language, but it is quite possible to understand the detailed drawings without knowing the language.

Free download instructions for the manufacture of the machine: Homemade CNC milling machine

The CNC milling machine is assembled and ready to go. Below are some illustrations from the assembly instructions for this machine.

"Patterns" of machine parts (reduced view) Beginning of machine assembly Intermediate stage Final assembly stage

Preparatory work

If you decide that you will design a CNC machine with your own hands without using a ready-made kit, then the first thing you need to do is to opt for circuit diagram, on which such mini-equipment will work.

Scheme of a CNC milling machine

The basis of CNC milling equipment can be taken from an old drilling machine, in which the working head with a drill is replaced with a milling head. The most complex thing that will have to be designed in such equipment is a mechanism that ensures the movement of the tool in three independent planes. This mechanism can be assembled on the basis of carriages from a non-working printer; it will ensure the movement of the tool in two planes.

It is easy to connect software control to a device assembled according to such a concept. However, its main drawback is that only workpieces made of plastic, wood and thin sheet metal can be processed on such a CNC machine. This is explained by the fact that the carriages from the old printer, which will ensure the movement of the cutting tool, do not have a sufficient degree of rigidity.

A lightweight version of the CNC milling machine for working with soft materials

In order for your homemade CNC machine to be able to perform full-fledged milling operations with workpieces from various materials, a sufficiently powerful stepper motor must be responsible for moving the working tool. It is not at all necessary to look for a stepper-type engine, it can be made from a conventional electric motor, subjecting the latter to a slight refinement.

The use of a stepper motor in your milling machine will make it possible to avoid the use of a screw drive, and the functionality and performance of home-made equipment will not worsen from this. If you still decide to use carriages from the printer for your mini-machine, then it is advisable to pick them up from a larger model of the printing device. To transfer force to the shaft of milling equipment, it is better to use not ordinary, but toothed belts that will not slip on the pulleys.

Belt drive unit

One of the most important components of any such machine is the milling mechanism. It is its manufacture that must be given Special attention. To properly make such a mechanism, you will need detailed drawings, which will need to be strictly followed.

CNC milling machine drawings

Drawing No. 1 (side view)

Drawing No. 2 (back view)

Drawing No. 3 (top view)

Let's start assembling the equipment

The basis of home-made CNC milling equipment can be a rectangular beam, which must be securely fixed on the rails.

The supporting structure of the machine must have high rigidity, it is better not to use welded joints during its installation, and all elements must be connected only with screws.

Unit for fastening machine frame parts by means of a bolted connection

This requirement is explained by the fact that welds tolerate vibration loads very poorly, which in without fail will be subject to Basic structure equipment. Such loads will eventually lead to the fact that the frame of the machine will begin to collapse over time, and changes in geometric dimensions will occur in it, which will affect the accuracy of equipment settings and its performance.

Welds when mounting the frame of a homemade milling machine, they often provoke the development of play in its nodes, as well as the deflection of the guides, which is formed under severe loads.

Installation of vertical racks

In the milling machine, which you will assemble with your own hands, a mechanism must be provided to ensure the movement of the working tool in a vertical direction. It is best to use a screw gear for this, the rotation of which will be transmitted using a toothed belt.

Important detail milling machine - its vertical axis, which for homemade device can be made from aluminum plate. It is very important that the dimensions of this axis are precisely adjusted to the dimensions of the device being assembled. If you have a muffle furnace at your disposal, then you can make the vertical axis of the machine with your own hands, casting it from aluminum according to the dimensions indicated in the finished drawing.

Top carriage assembly placed on transverse rails

After all the components of your homemade milling machine are prepared, you can begin to assemble it. This process begins with the installation of two stepper motors, which are mounted on the equipment body behind its vertical axis. One of these electric motors will be responsible for moving the milling head in the horizontal plane, and the second - for moving the head, respectively, in the vertical plane. After that, the remaining components and assemblies of home-made equipment are mounted.

The final stage of machine assembly

Rotation to all components of home-made CNC equipment should be transmitted only through belt drives. Before connecting a program control system to the assembled machine, you should check its performance in manual mode and immediately eliminate all identified shortcomings in its operation.

You can watch the process of assembling a milling machine with your own hands on a video that is easy to find on the Internet.

Stepper motors

In the design of any CNC milling machine, there are necessarily stepper motors that provide tool movement in three planes: 3D. When designing a homemade machine for this purpose, you can use electric motors installed in a dot matrix printer. Most older models of dot matrix printers were equipped with electric motors with fairly high power. In addition to stepper motors from an old printer, it is worth taking strong steel rods, which can also be used in the construction of your homemade machine.

Attaching the stepper motor to the top carriage

To make a CNC router with your own hands, you will need three stepper motors. Since there are only two of them in a dot matrix printer, it will be necessary to find and disassemble another old one. printing device.

It will be a big plus if the engines you find have five control wires: this will significantly increase the functionality of your future mini-machine. It is also important to find out the following parameters of the stepper motors you found: how many degrees it rotates in one step, what is the supply voltage, and also the value of the winding resistance.

You will need a separate controller to connect each stepper motor.

The drive design of a homemade CNC milling machine is assembled from a nut and a stud, the dimensions of which must first be selected according to the drawing of your equipment. To fix the motor shaft and to attach it to the stud, it is convenient to use a thick rubber winding from an electric cable. Elements of your CNC machine, such as clamps, can be made in the form of a nylon sleeve into which a screw is inserted. In order to make such simple structural elements, you will need a regular file and a drill.

Electronic filling of equipment

Your do-it-yourself CNC machine will be controlled by software, and you need to choose the right one. When choosing such software (you can write it yourself), it is important to pay attention to the fact that it is efficient and allows the machine to implement all its functionality. Such software should contain drivers for controllers that will be installed on your mini milling machine.

IN homemade machine with the CNC, the LPT port is obligatory, through which electronic system control and connect to the machine. It is very important that this connection is made through the installed stepper motors.

Wiring diagram for unipolar stepper motors for a 3-axis CNC machine (click to enlarge)

When choosing electronic components for your do-it-yourself machine, it is important to pay attention to their quality, since the accuracy of the technological operations that will be performed on it will depend on this. After installing and connecting all the electronic components of the CNC system, you need to download the necessary software and drivers. Only after that, a test run of the machine follows, checking the correct operation of the machine under the control of downloaded programs, identifying shortcomings and promptly eliminating them.

All of the above actions and the listed components are suitable for making a do-it-yourself milling machine not only for a coordinate boring group, but also for a number of other types. On such equipment, it is possible to process parts with a complex configuration, since the working body of the machine can move in three planes: 3d.

Your desire to assemble such a machine controlled by the CNC system with your own hands must be supported by the presence of certain skills and detailed drawings. It is also highly desirable to watch a number of thematic training videos, some of which are presented in this article.

Home › Equipment for metal processing › Milling machines

Similar news:

artemmian.ru

DIY CNC machine / DIY / Collective blog

Today, the CNC machine has a wide range of applications. Among the main operations performed on it, one can note the manufacture of furniture, stone processing, repair, construction work, etc.

A CNC machine made in an industrial environment is a rather expensive pleasure. But it turns out that the mechanism is complex at first glance, it is very simple and affordable to make at home with your own hands.

For the first experience, it is best to opt for a machine with a moving portal. This is due to the fact that it perfectly combines simplicity and functionality.

For the manufacture of the main parts of the machine, we take MDF boards. This material is a fine dispersed fraction, which is pressed under high pressure and temperature into one plate. The main characteristics of MDF include high density. Therefore, they are great for making CNC machines with your own hands. On MDF equipment, you can process plastic, wood, engrave, but process metal parts cannot be achieved with high accuracy. This is due to the low resistance of this material to loads.

To begin with, we will print the drawing of our machine on a printer. Then the resulting templates can be glued to the MDF. It is much easier and more convenient to cut out the details of the future machine.

The fittings that will be used in the assembly can be purchased at any hardware or hardware store.

In addition to accessories for the manufacture of the machine, the following tools will be required: a drill, a screwdriver and a hacksaw. If you have a jigsaw, then it is better to use it. This will greatly simplify the process of cutting out parts.

We proceed to the manufacture of the machine. To do this, we paste the drawings of the parts printed on the printer onto the MDF board using an adhesive stick for paper. When choosing it in the store, opt for the thickest one. This will significantly speed up the process of gluing templates.

Now you can do the direct sawing of blanks. In this model, all parts have almost straight lines and the most simple contours.

After all the templates are cut out, we proceed to drilling the holes. It should be noted that many of them have large diameter. Therefore, in order for the surface of these holes to be neat and smooth, it is better to use crowns or grinding nozzles. Thus, you will be able to accurately bore holes to the desired diameter.

Now you can start assembling the CNC machine according to the drawings we have.

Since we plan to use the machine at home, it is imperative to install a fence. This will avoid the scattering of dust and dirt from the workpieces.

For these purposes, you can use foam, fiberglass, thin plywood, etc. Don't forget to make a small hole in the fence.

Through it it will be possible to connect the hood from the old vacuum cleaner. This will ensure maximum trapping of dust and chips. The opposite effect of using such a "dirt trap" is a lot of noise.

The next important step in assembling a CNC machine with your own hands is electronics. After all, it is important, because. with its help, the management process takes place.

In this case, two solutions can be used. The first of them is to assemble the necessary controller circuit on your own, having bought all the necessary parts.

The second way is easier - buy a ready-made controller in a store or on the radio market. Which of the proposed paths to choose is up to you. If you are not very versed in radio engineering and decide to buy a finished part, then it is recommended to opt for the TV6560.

The choice of this element is evidenced by its ability to select the necessary power depending on the stepper motors used, the presence of protection against overload and overheating, the use of many software, etc.

If you will make the controller yourself, an old scanner or MFP is perfect. A ULN2003 chip, steel rods and a stepper motor are selected from it. In addition, you will need a DB-25 connector with a wire, a socket for powering the controller itself. If you want to have a computer control of your machine, then you will need a computer to which you will connect the received equipment.

To create a controller, we take any board we have. We carefully solder the ULN2003 chip onto it with a soldering iron. In this case, do not forget about polarity.

The above diagram shows that there are two power rails. Therefore, we solder the output of the microcircuit with a negative sign to one, and with a positive sign to the other. After that, we connect pin 2 of the parallel port connector to pin 1 of the ULN2003. To pin 2 of the ULN2003 we attach pin 3 of the connector. Accordingly, we will connect the output of the ULN2003 4 circuit to the 5th output of the connector, etc. But the zero pin with the 25th pin of the parallel port, we solder to the negative bus.

The next step is soldering the stepper motor to the control device. It can be done correctly only by trial and error, because. most often there is no documentation for the output of the electric motor you have. Therefore, it is recommended to equip the motor wires with crocodile clips. Thus, the process will go faster and easier.

Our next step is to connect the wires to pins 13,14,15,16 of the ULN2003 chip. Now we will solder the wires to the power bus with a plus sign. Finally, install the power socket.

Our controller is almost ready. Now we install it on steel rods and fix it in the nests prepared earlier. In order to prevent breakage of wires during operation, it is better to fix them with hot glue.

44kw.com

Drawing homemade CNC machine

You can download a drawing of a homemade CNC machine using the links at the end of the article.

You can download a drawing of a homemade CNC machine using the links at the end of the article.

The archive offered for download contains a drawing of a CNC machine for do-it-yourself assembly.

This is a fairly common type of CNC machine with a moving portal.

This drawing differs primarily in that in not only detailing is given - when each part of the machine is drawn separately and has dimensions, but also assembly drawings of each of the nodes are given.

A CNC machine according to such a drawing can be made from almost any material. It can be duralumin plates and plywood. You can also use durable plastic or plexiglass in the design of a homemade CNC machine.

The drawings are in DXF vector format and can be scaled to any size.

In the simplest case, you can take engines from dot matrix printers type Epson FX1000 A3 format, from the same printer take steel guides along with the sliding unit.

As a lead screw budget option a homemade CNC machine uses a stud with an M6 or M8 thread. It is better to order running nuts to a turner and turn them from bronze. A bronze nut can "walk" for 5-7 years with daily use of the CNC machine for 8-10 hours.

Lead screws are consumables, and lead nuts can serve more than one home-made machine.

However, I have read more than once about how they used running nuts made of plastic or getinaks.

A homemade CNC machine made from improvised means will allow you to process wood, plastics and non-ferrous metals.

For the processing of metals and steel, such a machine becomes unsuitable due to the weak rigidity of the structure.

However, it can be used for engraving or as a CNC-controlled drilling machine for metals.

But here's how milling - unlikely. When milling metals, shock loads occur - for example, when milling one groove, another groove meets and then a mechanical shock occurs, which is transmitted to the machine structure and the lead screw.

For homework, such as milling balsa model aircraft kits, this machine will easily justify the cost of making it!

You can download drawings of a homemade CNC machine here: Depositfiles or from our website

Homemade CNC machine