Interfloor overlapping on wooden beams: calculation of prefabricated loads and allowable deflection. Skull block in the process of building floors Stage #1

If the construction of a two-story or one-story house, but with a basement or attic, it is necessary to correctly calculate and build interfloor ceilings. Consider the stages and nuances of the implementation of the overlap on wooden beams and calculate the sections of the beams that provide sufficient strength.

The device of interfloor ceilings needs special attention, after all, made "by eye", they may not withstand the loads on them and collapse, or require unnecessary, unreasonable costs. Therefore, one or more possible options must be comprehensively considered and calculated. The final decision can be made by comparing the cost or availability of acquiring materials.

Requirements for interfloor ceilings

Interfloor ceilings must withstand constant and variable loads, that is, in addition to their own weight, withstand the weight of furniture and people. They must be sufficiently rigid and not allow the maximum deflection to be exceeded, provide sufficient noise and heat insulation.

Specific loads from furniture and people for living quarters are taken in accordance with the standards. However, if you plan to install something massive, for example, a 1000 l aquarium or a fireplace from natural stone, this must be taken into account.

The rigidity of the beams is determined by calculation and is expressed in the allowable bending per span. Permissible bending depends on the type of flooring and the flooring material. The main limit deflections determined by SNiP are shown in Table 1.

Table 1

| Structural elements | Limit deflections in span fractions, no more |

| 1. Beams of floors | 1/250 |

| 2. Beams of attic floors | 1/200 |

| 3. Coatings (except valleys): | |

| a) runs rafter legs | 1/200 |

| b) cantilever beams | 1/150 |

| c) trusses, glued beams (except for cantilever beams) | 1/300 |

| d) plates | 1/250 |

| e) battens, flooring | 1/150 |

| 4. Bearing elements of valleys | 1/400 |

| 5. Panels and fachtop elements | 1/250 |

| Notes: 1. In the presence of plaster, the deflection of the floor elements only from a long-term temporary load should not exceed 1/350 of the span. 2. In the presence of a construction lift, the maximum deflection of glued beams can be increased up to 1/200 of the span. |

|

Please note that flooring in the form of ceramic tiles or concrete screed, prone to cracking, can further tighten the requirements for allowable deflection, especially with sufficiently long spans.

To reduce the loads on the beams, if possible, they should be placed parallel to the short walls, with the same pitch. Maximum length span when overlapping them with wooden beams - 6 m.

Types of floors

According to the purpose of the overlap are divided into:

- interfloor;

- attic;

- basement (basement).

The features of their design are in the permissible loads and the device of steam and heat insulation. If the attic is not intended for living or storing massive objects, variable loads can be reduced to 50-100 kg / m 2 when calculating the deflection.

Thermal insulation between two residential floors may seem redundant, but sound insulation is a desirable parameter for the majority, and this is achieved, as a rule, with the same materials. It should be taken into account that attic and basement floors need a thicker layer of thermal insulation material. Film material for vapor barrier in attic floor should be located under a layer of insulation, and in the basement - above it. To prevent the occurrence of dampness and damage to structures by a fungus, all rooms must be equipped with ventilation.

Floor options: 1 - plank shield; 2 - vapor barrier; 3 - thermal insulation; 4 - sparse flooring; 5 - boards; 6 - flooring

Floor options: 1 - plank shield; 2 - vapor barrier; 3 - thermal insulation; 4 - sparse flooring; 5 - boards; 6 - flooring

The design of the floors can also be different:

- with open and hidden beams;

- with various types bearing beams;

- with different materials filling and lining of the floor.

Hidden beams are sewn on both sides and are not visible. Open - protrude from the ceiling and serve as decorative elements.

The figure below shows what the structure of the overlap can be. attic floor with a shield roll and with a filing of boards.

a - with a shield roll; b - with filing from boards; 1 - plank floor; 2 - polyethylene film; 3 - insulation; 4 - vapor barrier; 5 - wooden beams; 6 - cranial bars; 7 - shield reel; 8 - finishing; 9 - filing from boards

a - with a shield roll; b - with filing from boards; 1 - plank floor; 2 - polyethylene film; 3 - insulation; 4 - vapor barrier; 5 - wooden beams; 6 - cranial bars; 7 - shield reel; 8 - finishing; 9 - filing from boards

Types of fastenings and connections of wooden beams

Depending on the design and material of the load-bearing walls, wooden beams are attached:

- in the nests provided in the brick or block masonry, deepening the beam or log at least 150 mm, and the board at least 100 mm;

- on the shelves (ledges) provided in the brick or block masonry. It is used if the wall thickness of the second floor is less than the first one;

- into cut grooves in log walls to a depth of at least 70 mm;

- to the top rail frame house;

- to metal supports-brackets fixed on the walls.

1 - support on a brick wall; 2 - solution; 3 - anchor; 4 - roofing felt insulation; 5 - wooden beam; 6 - support on wooden wall; 7 - bolt

1 - support on a brick wall; 2 - solution; 3 - anchor; 4 - roofing felt insulation; 5 - wooden beam; 6 - support on wooden wall; 7 - bolt

If the length of the beam is not enough, you can lengthen it by connecting (joining) along the length using one of the known methods using wooden pins and wood glue. When choosing the type of connection, be guided by the direction of application of the load. It is desirable to strengthen the spliced beams with metal plates.

a - compression; b - stretching; c - bend

a - compression; b - stretching; c - bend

About wooden beams

In construction, beams of rectangular, round or partially round section are used. The most reliable are rectangular lumber, and the rest are used in the absence of timber or for reasons of economy, if such materials are available on the farm. Glued wood materials have even greater strength. Beams made of glued beams or I-beams can be installed on spans up to 12 m.

The most inexpensive and popular type of wood is pine, but other types of conifers are also used - larch, spruce. Floors are made of spruce in summer cottages, small houses. Larch is good for building premises with high humidity(bath, pool in the house).

The materials also differ in grade, which affects the bearing capacity of the beams. Grade 1, 2 and 3 (see GOST 8486-86) are suitable for floor beams, but grade 1 for such a design may be unnecessarily expensive, and grade 3 is best used on small spans.

Calculation of load-bearing beams

To determine the section and step of the beams, it is necessary to calculate the load on the ceiling. The collection of loads is carried out according to the methodology and taking into account the coefficients set forth in SNiP 2.01.07-85 (SP 20.13330.2011).

Load calculation

The total load is calculated by summing the constant and variable loads, determined taking into account the standard coefficients. In practical calculations, they are first set by a certain design, including the preliminary layout of beams of a certain section, and then corrected based on the results obtained. So the first step is to sketch all the layers of the "pie" overlap.

1. Own specific gravity of the overlap

The specific gravity of the floor is the sum of its constituent materials and is divided by the horizontal total length of the floor beams. To calculate the mass of each element, you need to calculate the volume and multiply by the density of the material. To do this, use table 2.

table 2

| Material name | Density or bulk density, kg / m 3 |

| asbestos cement sheet | 750 |

| Basalt wool (mineral) | 50-200 (depending on the degree of compaction) |

| Birch | 620-650 |

| Concrete | 2400 |

| Bitumen | 1400 |

| Drywall | 500-800 |

| Clay | 1500 |

| Chipboard | 1000 |

| Oak | 655-810 |

| Spruce | 420-450 |

| Reinforced concrete | 2500 |

| Expanded clay | 200-1000 (from foam ratio) |

| Expanded clay concrete | 1800 |

| Brick solid | 1800 |

| Linoleum | 1600 |

| Sawdust | 70-270 (from fraction, wood species and humidity) |

| Parquet, 17 mm, oak | 22 kg/m2 |

| Parquet, 20 mm, panel | 14 kg/m2 |

| foam concrete | 300-1000 |

| Styrofoam | 60 |

| Ceramic tiles | 18 kg/m2 |

| Ruberoid | 600 |

| Wire mesh | 1.9-2.35 kg / m 2 |

| Pine | 480-520 |

| Carbon steel | 7850 |

| Glass | 2500 |

| glass wool | 350-400 |

| Plywood | 600 |

| cinder block | 400-600 |

| Plaster | 350-800 (from composition) |

For wood-based materials and waste, the density depends on the moisture content. The higher the humidity, the heavier the material.

Partitions (walls) also belong to constant loads, the specific weight of which is taken approximately 50 kg / m 2.

The decor of the room, people, animals - all this is a variable load on the floor. According to Table. 8.3 SP 20.13330.2011, for residential premises, the standard distributed load is 150 kg / m 2.

The total load is not determined by simple addition, it is necessary to take the reliability factor, which, according to the same SNiP (clause 8.2.2), is:

- 1.2 - with a specific gravity of less than 200 kg / m 2;

- 1.3 - with a specific gravity of more than 200 kg / m 2.

4. Calculation example

As an example, let's take a room with a length of 5 and a width of 3 m. Every 600 mm of length we put beams (9 pcs.) Of pine with a section of 150x100 mm. We will block the beams with a board 40 mm thick and lay linoleum 5 mm thick. From the side of the first floor, we will sew the beams with plywood 10 mm thick, and inside the ceiling we will lay a layer of mineral wool 120 mm thick. Partitions are absent.

1 - beam; 2 - board; 3 - insulated linoleum 5 mm

1 - beam; 2 - board; 3 - insulated linoleum 5 mm

The calculation of the constant specific load on the area of the room (5 x 3 \u003d 15 m 2) is shown in table 3.

Table 3

Design load on the beam (qр) - 250 x 0.6 m = 150 kg / m (1.5 kg / cm).

Allowable deflection calculation

We accept the permissible deflection of the interfloor ceiling - L / 250, i.e. for a three-meter span, the maximum deflection should not exceed 330 / 250 = 1.32 cm.

Since the beam lies on the support at both ends, the calculation of the maximum deflection is carried out according to the formula:

- h = (5 x qp x L4) / (384 x E x J)

For our example:

- h \u003d (5 x 1.5 x 3304) / (384 x 100000 x 2812.5) \u003d 0.82 cm

The result obtained in comparison with the allowable deflection has a margin of 60%, which seems excessive. Therefore, the distance between the beams can be increased by reducing their number and repeat the calculation.

In conclusion, we suggest watching a video on calculating the floor on wooden beams using a special program:

And the demands placed on them

Functional purpose, classification of floors

Ceilings and floors

Floors, like walls, are the main structural parts of buildings. . Overlappings- This structural element, which performs load-bearing and enclosing functions. In this regard, the ceilings consist of a bearing part that receives the load and transfers it to walls or other supports, and an enclosing part, which also includes floors and ceilings.

Depending on the location, the floors are interfloor, attic, above the basement and lower, and, accordingly, they have different enclosing functions. Interfloor ceilings divide the premises in height and provide their sound insulation, while attic, above basement and lower floors additionally protect the premises from temperature differences.

Depending on the material and design of the bearing part of the floor, there are wooden beams, steel beams and reinforced concrete, and according to the design solution and method of flooring, there are: 1) prefabricated beams; 2) combined; 3) monolithic; 4) prefabricated monolithic.

Prefabricated beam ceilings consist of load-bearing beams and the enclosing part - rolling slabs with backfill for sound insulation or insulation. Instead of backfill, slab insulating or soundproofing materials can be laid. AT combined floors bearing and enclosing functions perform the same elements. Combined floors include reinforced concrete floor slabs or panels. Monolithic reinforced concrete floors are arranged in a building under construction using formwork and they consist of beams and slabs molded as a whole or can be beamless. Prefabricated monolithic ceilings they are also arranged at the construction site with the use of special insert stones or prefabricated reinforced concrete elements in their construction, which, when they are concreted (monolytic), can partially play the role of formwork.

Ceilings must meet the requirements for strength, rigidity, fire resistance, durability, provide the required sound insulation, and, if necessary, thermal insulation. Ceilings of rooms with wet processes must be waterproof, and in rooms with gas evolution - gas-tight.

Ceilings on wooden beams are used in wooden buildings, and they can also be used in buildings with stone (preferably with internal transverse load-bearing) walls in the following cases: residential buildings height up to 4 floors, in buildings of cultural and community institutions - up to 3 floors and in buildings for children's institutions - up to 2 floors. Wooden floors consist of beams, which are the bearing part, and inter-beam filling, designed for sound and heat insulation. Filling consists of a supporting part - rolling and filler. The composition of the ceiling also includes the floor and the finishing layer of the ceiling.

Wooden beams are rectangular bars. Beams can also be made from boards joined with glue or nails. The size of the cross section of the beams is from 80x180 mm to 100x240 mm, depending on the length of the beams and the perceived loads. In table. 2 shows the recommended dimensions of the cross sections of the beams, depending on their length.

table 2

Dimensions wooden beams

The so-called cranial bars with a section of 40x50 mm are nailed to the side surfaces of the beams near the lower edge (Ø 4–5 mm; length 125 mm; step 300 mm) to rest the roll-up shields on them. In board beams glued or assembled on nails, protruding shelves can be arranged instead of cranial bars.

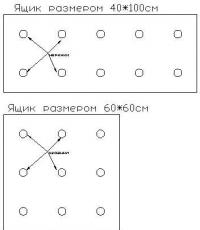

The distance between the axes of the beams on the plan depends on the overlapped span and the perceived load. It ranges from 600 to 1100 mm. On fig. 21.1 shows wooden beams with cranial bars.

Rice. 21.1. Wooden beams with cranial bars: a - general form; b, c - cross-sections of beams of the BD type (with two cranial bars) and BO (with one cranial

As a reel, wooden elements are used, for example, from slabs, but wooden shields are more often used with solid support or leaning on planks(Fig. 21.2) .

Rice. 21.2. Wooden boards of rolling: a - with continuous support on cranial bars; b - with intermittent support on transverse slats

In addition to wooden shields, ribbed or hollow gypsum or lightweight concrete slabs can serve as a coaster. Such rolls are heavier than wood, but they are non-flammable and do not rot. The width of the rolling elements depends on the distance between the beams, and their length is taken taking into account the fact that such ceilings are assembled manually. On fig. 21.3 shows a fragment of the floor plan for wooden beams.

To ensure the required sound insulation along the laid reel, they arrange clay-sand putty 20–30 mm thick and slag or dry calcined sand is poured on it with a layer 60–80 mm thick. Clay-sand putty serves for sealing the boards of the run-up and the places where the run-up adjoins the beams. Instead of clay-sand putty, roofing felt or roofing material can be used. In attic floors and in ceilings above cold basements and undergrounds, backfill performs the function of thermal insulation and its thickness is determined by the calculation for thermal protection (Fig. 21.4).

Rice. 21.3. Fragment of floor plan on wooden beams

Floors made of boards on wooden beams are laid on logs of plates laid across the beams every 500–700 mm, or directly on the beams (with a step between them of no more than 0.7 m). If the floor is laid along the logs, then the ventilation of the underground space is provided through the ventilation grills installed in the floor in the corners of the rooms, or through the slotted skirting boards, and if the floor is laid directly along the beams, then the ventilation of the underground space between the beams is provided through slotted skirting boards or ventilation grilles cut into the skirting boards . plinth called wooden block shaped profile, nailed to the wall, and fillet- nailed to the floor.

Rice. 21.4. Ceilings on wooden beams: a - attic with rolling from slabs; b - interfloor with rolling from slabs; c - the same with the rolling of their shields; 1 - beam; 2 - reel from slabs; 3 - shield reel; 4 - clay-sand putty; 5 - filling from slag or calcined sand; 6 - roofing pad; 7 - log; 8 - floor covering from boards; 9 - plaster

bottom surface wooden floors(ceiling) is plastered on shingles or upholstered with sheets of dry plaster from drywall (see Fig. 21.4 and 21.5).

Rice. 21.5. Design variant of a wooden interfloor ceiling with a parquet floor: 1 - cranial bars; 2 - beam; 3 - parquet; 4 - black floor; 5 - log; 6 - plaster; 7 - roll-up shield; 8 - clay-sand putty; 9 - backfill

Rice. 21.6. Supporting wooden beams on the outer walls: a - blind embedment; b - open seal

The depth of embedding wooden beams in the walls must be at least 180 mm. The supporting ends of the beams are antiseptic to a length of 750 mm to prevent decay, and the surfaces of the supporting sections are covered with two layers of roofing paper on resin. To ensure the possibility of evaporation of moisture from the supporting parts of the beams, their ends are made beveled and not covered with roofing paper, and a gap of at least 30 mm is left between the end of the beam and the wall masonry. The side and upper gaps between the beams and the masonry walls are filled with mortar, and for dry rooms a gap of 30–50 mm is left above the beam (Fig. 21.6). Perpendicular pairing between wooden beams is arranged using notches or steel clamps (Fig. 21.7).

Rice. 21.7. Options for pairing wooden beams with each other: a - using a cut; b - using a steel clamp; 1, 2 - beams; 3 - steel clamp

Options for supporting wooden beams on internal walls, having a thickness of 380 mm or less, are shown in fig. 21.8.

Rice. 21.8. Supporting wooden beams on internal walls: a - in damp rooms (blind embedment); b - in dry rooms (open termination)

To increase the rigidity and stability of the walls and the building as a whole, the ends of the wooden beams are fixed through one into the masonry of the outer walls using steel anchor plates, and the ends of the beams on the inner walls are connected with steel plate plates every 3 beams.

As a rule, in stone buildings with wooden floors in sanitary facilities, reinforced concrete prefabricated or monolithic floors are arranged, but it is also possible to install floors in these places along wooden beams (Fig. 21.9). In this case, a continuous flooring of 50-60 mm thick bars is laid along the beams, then a waterproofing carpet is laid over the flooring and a reinforced layer of cement mortar is laid on it, and a clean floor of ceramic tiles. All wooden elements in such ceilings are antiseptic, and the beams below are left open for better ventilation.

Rice. 21.9. Wooden floor of the sanitary unit: 1 - ceramic tiles; 2 - reinforced screed from cement-sand mortar; 3 - waterproofing; 4 - flooring from tongue-and-groove bars

Individual and low-rise residential buildings are often built with wooden beam ceilings. They consist of a load-bearing wooden beam, floor, inter-beam filling, which is heat and sound insulation, and a separate layer (ceiling). The lower part of the interbeam filling is called coasting and is a flooring supporting a layer of heat and sound insulation of the upper part of the inter-beam ceiling.

The wooden beams of the floor of the first floor are laid on brick pillars, on the basement of the building or cut in with a frying pan between the first and second crown. Sometimes it is advisable to cut the overlap between the second and third crown. This is done in order to crown crown, which takes the load from the walls, was not weakened by the cutting of the ceiling. When leaning on brickwork, special nests for beams are made in it. Wooden beams are laid at a distance of 0.6 ... 1 m from each other, which depends on the design of the ceiling.

Rice. 1. The design of the beam ceiling on wooden beams with rolling:

1 - beam; 2 - cranial bars; 3 - shields from boards; 4 - lime or clay lubricant; 5 - sand to enhance sound insulation; 6 - cardboard gasket; 7 - lag; 8 - floor along the lags; 9 - plaster.

If the floor is laid on the beams from boards (28 mm thick), then it should not be more than 0.5 m. If the floor consists of beams of a larger section, on which logs are laid, and then floorboards, then the beams can be laid in increments of 1 m. Wooden beams usually cover spans up to 4 ... 4.5 m. For large spans, it is more expedient to use reinforced concrete beams.

Rice. 2. Overlapping on block beams:

1 - cranial bars; 2 - cardboard; 3 - parquet; 4 - black floor; 5 - lag; 6 - plaster; 7 - reel; 8 - clay lubricant; 9 - backfill.

Most often used as beams wooden bars from coniferous wood, rectangular in section with bars nailed to them with a section of 40x40 - 50x50 mm, which are called cranial bars. They are designed to support the roll of wooden shields. In addition, you can use logs with partially cut sides in them to support the boards.

Rice. 3. Wooden beam with skull bars:

a - general view;

b, c - cross sections of beams;

d, d - a beam with a skull;

1 - cranial bar.

The height of the beam depends on the span and must be at least 1/24 of its length. The width of the section depends on the height of the beam. The optimal ratio of cross-sectional dimensions is 7:5. Instead of beams, thick boards can be used: the total cross section of two boards should be equal to the cross section of the beam. Ordinary thick boards are also used, placed on the edge with a step 3 times smaller than the bars.

When laying the floor, the first and last beam must not be laid so that it is in contact with the wall. Between them it is necessary to arrange a gap about 30 mm wide. The beams rest on bearing walls, deepening the ends by 150 ... 200 mm. The beams are rolled up from edged boards with a thickness of 24 mm, laid tightly to each other. So that insulating and soundproofing backfill does not wake up in the seams between the boards, wooden planks with a section of 30x50 mm or strips of roofing material are placed on them. On the reel, a backfill with a thickness of about 80 mm is arranged, on top of which logs are laid, to which the floor is usually nailed from tongue-and-groove boards. From below, a filing of thin boards 12 ... 18 mm thick is nailed to the beams.

The structure of the floors and the materials used for their construction are fully dependent on the design of the building. In buildings of frame or frame-panel construction, the floors are made of wood, since the frame of the house is not designed for heavier loads. Here we can say with confidence that the ceiling is also a fence, with the only difference being that it is located in a horizontal plane. Despite this, the order of installation of the ceiling is somewhat different from the wall structures.

The bearing basis of the frame of the wooden floor are ceiling beams, which are included in the scheme power frame building. They perceive the load of their own weight, filling, as well as operational loads, transferring them to runs or poles.

:

A - attic floor with a "black" ceiling; B - attic with a hemmed plank ceiling and running deck; B - interfloor overlap without sound insulation; G - overlap with increased sound insulation; D - basement with plank filing;

1 - a layer of thermal insulation; 2 - layer of vapor barrier; 3 - "black" ceiling; 4 - filing; 5 - running flooring; 6 - floor; 7 - beam; 8 - dry filling; 9 - bedding; 10 - elastic lining; 11 - cranial bar

:

1 - beams; 2 - run; 3 - bolt; 4 - spike; 5 - stripes; 6 - pillar; 7 - pillow

For the installation of floors, beams are selected whose bearing capacity meets the requirements. Beams are made of round timber, processed into four edges, timber or boards 60-80 mm thick, installed on the edge. It is allowed to use paired boards with a thickness of 50 mm, which are "sewn" together with nails or metal staples. It is even better if you form an I-beam or a box structure from boards. For large spans, the middle part of the beams is supported on internal walls or on intermediate pillars. In any case, the choice of load-bearing beams is influenced by the magnitude of the loads. Permissible sections of beams of interfloor and attic floors, depending on the span, at a load of 400 kg per 1 m 2.

| Permissible sections of beams of interfloor and attic floors, depending on the span at a load of 400 kg per 1 m2 | |||

| Span, m | Distance between beams, m | Log diameter, cm | Cross section of bars, cm |

| 2 | 1 | 13 | 12*8 |

| 0,6 | 11 | 10*7 | |

| 2,5 | 1 | 15 | 14*10 |

| 0,6 | 13 | 12*8 | |

| 3 | 1 | 17 | 16*11 |

| 0,6 | 14 | 14*9 | |

| 4 | 1 | 21 | 20*12 |

| 0,6 | 17 | 16*12 | |

| 4,5 | 1 | 22 | 22*14 |

| 0,6 | 19 | 18*12 | |

| 5 | 1 | 24 | 22*16 |

| 0,6 | 20 | 18*14 | |

| 5,5 | 1 | 25 | 24*16 |

| 0,6 | 21 | 20*14 | |

| 6 | 1 | 27 | 25*18 |

| 0,6 | 23 | 22*14 | |

| 6,5 | 1 | 29 | 25*20 |

| 0,6 | 25 | 32*15 | |

| 7 | 1 | 31 | 27*20 |

| 0,6 | 27 | 26*15 | |

The loads on the floors are made up of their own mass and temporary loads that arise during the operation of the house. The own weight of interfloor wooden floors depends on the design of the floor, the insulation used and is usually 220-230 kg / m2, attic - depending on the weight of the insulation is 250-300 kg / m2. Temporary loads on the attic floor are taken as 100 kg / m2, on the interfloor - 200 kg / m2. In order to determine the total load that falls on one square meter overlappings during the operation of the house, add up the temporary and own loads, and their sum is the desired value. Depending on the bearing capacity of the beams, the length of their span and the magnitude of the operational loads, the distance between the beams is chosen, which usually lies in the range of 0.5-1m.

:

1 - drywall sheets; 2 - floor shield made of tongue-and-groove boards; 3 - waterproofing layer; 4 - sound insulation layer; 5 - beam; 6 - lag; 7 - floor boards; 8 - cranial bars beams

Comfortable flooring suit for non-residential premises, since the sound-absorbing and heat-insulating properties of such an overlap are rather low. The essence of the overlap is that a flooring made of boards is sewn between the load-bearing beams, which serves as the floor of the attic. Hemmed overlap is most often used in country houses attic type, which are operated seasonally, and there are no high requirements for the thermal insulation properties of the floor. The essence of the overlap is that on both sides of the beams, a flooring of tongue-and-groove boards is attached. The sound-absorbing layer is laid directly on the boards of the lower filing. The lower floor serves as the ceiling of the lower floor, and the upper one serves as the floor of the attic. In cases where the lower flooring, which serves as the ceiling of the first floor, is planned to be plastered, then the boards should be taken without grooves and a gap should be left between them. So that cracks do not form in the floorboards when the plaster dries and they do not warp, they make punctures along the entire length, into which wooden wedges are hammered. Plastering hemmed ceilings on shreds.

Rice. 112.:

A - with insulation: 1 - beams; 2 - cranial bars; 3 - black floor; 4 - glassine; 5 - insulation; 6 - glassine; 7 - floor boards;

B - rolling on cranial bars with sound insulation: 1 - beams; 2 - cranial bars; 3 - filing the ceiling; 4 - roll-over shields; 5 - sound insulation; 6 - glassine; 7 - floor boards;

B - rolling on beams without cranial bars: 1 - beams; 2 - boardwalk; 3 - glassine; 4 - insulation; 5 - draft floor; 6 - finishing floor

:

A - from scraps; B - from bars; B - with reinforcement with metal brackets; G - using longitudinal samples

Backfill on the boards of the lower flooring can tear off the boards from the beams, so its weight is limited. When constructing such ceilings, it is possible to use backfilling only with a low bulk density (sawdust, husks, etc.). Ceilings with a rolling device are built for residential buildings when the requirements for the insulating properties of the building envelope are increased. This type of ceiling more fully meets the soundproofing and heat-saving requirements. To do this, a reel is installed along the load-bearing beams, which serves to absorb the load from the insulating layer and to transfer it to the beam. Rolls can be in the form of shields assembled from longitudinal or transverse boards. The shields rest on holes (cranial bars) nailed to the side faces of the beams. Installation of the ceiling begins with the installation of load-bearing beams. Wooden beams are laid, as a rule, along a short section of the span, as parallel as possible to each other and with the same distance between them. In this case, the distance between the beams must correspond to the distance between the load-bearing posts of the load-bearing frame of the walls. The beams are laid in the "lighthouse" way - first, the outer beams are installed, and then the intermediate ones. The correctness of the position of the extreme beams is verified with a level or spirit level, and the correctness of the intermediate ones is checked with a rail and a template. Beams should not have defects that affect their strength characteristics(a large number of knots, slanting, graininess, etc.). Beams are subject to mandatory antiseptic and fire impregnation.

:

1 - plinth; 2 - beam (60x180 mm); 3 - grooved floorboards (40 mm); 4 - filling with expanded clay; 5 - a layer of roofing felt or roofing material; 6 - rolling from boards (25 mm); 7 - cranial bar (50x50 mm); 8 - tarred board (200x50 mm); 9 - drain board (200x50 mm); 10 - waterproofing (2 layers of roofing material on hot bituminous mastic); 11 - tarred board 100x40 mm; 12 - flooring from boards 30 mm thick; 13 - filing from boards (25 mm); 14 - grooved boards (30 mm); 15 - logs 80x40 mm through 400 mm; 16 - gasket 25 mm thick every 500 mm; 17 - a layer of cement-sand mortar with a thickness of 20-50 mm; 18 - boardwalk (40 mm)

The floor beams are cut into the bars of the upper strapping of the wall frame above the supporting racks of the frame (Fig. 114). The ends of the beams are brought out of the wall to form a cornice overhang, which will protect the walls from atmospheric precipitation. The cranial bars are nailed to the sides of the beams, aligning their lower part in the same plane with the beams. To do this, they usually take bars with a section of 40x40 or 40x50 mm from coniferous wood. The fastening of the cranial bars must be secure enough to support the weight of the insulating backfill. Instead of cranial bars, you can nail angle steel, on one of the shelves of which roll-up shields are installed. As a reel, you can use single-layer shields made of bakelized plywood, boards, slabs, fiberboard, gypsum slag and other sheet materials that can withstand the weight of the backfill, etc. The reel plates are tightly fitted one to the other. Most often, a quarter is chosen at the ends of the underlying boards so that their lower surface is in the same plane as the surface of the beam. When constructing a roll and flooring, it should be remembered that the more wooden elements is present in the ceiling, the more the probability of their vibration under loads increases, which becomes additional source noise. To reduce this probability, it is advisable to connect all the elements of rolling and flooring into a sheet pile.

On the reel, a layer of roofing paper or glassine is laid, on which they are laid thermal insulation material: mineral wool, granular slag, perlite, expanded clay or another type of insulation, the properties of which we have already considered. When insulating the attic floor, porous bulk materials (slag, expanded clay, etc.) are treated on top with a liquid sand-lime mortar to form a crust. The crust will serve as a protective layer against dust. The type of insulation and its thickness are determined depending on the estimated outside air temperature, using table 20 for this.

| Table 20. Attic floor backfill thickness depending on the outdoor temperature | ||||

| Material | Volume weight, kg/m3 | Backfill thickness (mm) at outdoor temperature, °C | ||

| -15 | -20 | -25 | ||

| sawdust | 250 | 50 | 50 | 60 |

| Wood shavings | 300 | 60 | 70 | 80 |

| Agloporite | 800 | 100 | 120 | 140 |

| Boiler slag | 1000 | 130 | 160 | 190 |

The ceiling is hemmed with boards, sheet materials (fiberboard, chipboard, drywall) or one of the types decorative panels entering the modern trading network. Filing with plasterboard sheets increases the fire resistance of the structure. The top flooring is best done double. First, boards 20 mm thick are laid, cardboard is laid on them, and only after that the floor of the second floor is laid. In attics that are not supposed to be used, the top flooring may not be performed. Instead, boards are installed in the places of the alleged emergency passage. Such flooring is called walk-through boards.

The disadvantages of all wooden floors include their increased sensitivity to operating conditions. This is especially evident in the basement ceilings. The fact is that any structure of overlapping with the floor has, to one degree or another, vapor impermeability. Therefore, with appropriate air humidity and a sufficient temperature difference inside the house and outside, vapor condensation begins. Vapors, condensing on wooden structures, cause them to saturate with moisture and become the cause of rotting of the wood. To eliminate this, in the basement of the house they arrange ventilation for underground ventilation or equip special ventilation wells.

Particular attention should be paid to wooden floors in rooms with possible moisture (bathrooms, bathrooms, etc.). In such premises, it is better to perform ceilings with a waterproofing layer, the ends of which rise up to a height of at least 100 mm. A drain can be installed in the floor of the room, through which spilled water will be spontaneously removed. Beams from below should not be closed, as the lack of ventilation can lead to the formation of dampness and mold. The absence of a bottom binder will make it possible to control the state of the overlap.

Dedyukhova I.A., Ph.D., Associate Professor

Wood flooring is one of the main constructive solutions floors and in new low-rise construction. The main advantage of such ceilings is their lightness, which allows them to be installed without the involvement of lifting mechanisms and lifting devices.

In housing in the capitalization group "Ordinary" before industrialization construction industry in the 60s of the last century, wooden floors were not only the most economical, but in some cases - the only possible option, due to the lack of lifting mechanisms. Wooden floors are easy to manufacture, have low thermal conductivity, but lower mechanical strength, requiring large sections; low fire resistance and resistance to damage by microorganisms and termites - impose special requirements on their operation.

Wooden floors consist of a load-bearing wooden beam, floor, inter-beam filling, which is heat and sound insulation, and a separate layer (ceiling). The lower part of the inter-beam filling is called a run-up and is a flooring that supports a layer of heat and sound insulation of the upper part of the inter-beam ceiling.

Sand, slag, expanded clay and other bulk materials were most often used as soundproofing.

The reel serves to take the load from the insulating layer and transfer it to the beam. Roll-ups can be in the form of: boards from longitudinal boards, boards from transverse boards and boards from longitudinal and transverse boards. The shields rest on holes (cranial bars) nailed to the side faces of the beams. To do this, cranial bars with a section of 40 × 40 or 50 × 50 mm are nailed to the beams.

To ensure better sound insulation from airborne sound transfer along the run-up in housing of the III capital group, a clay-sand lubricant 20–30 mm thick was made, on top of which slag or dry calcined sand 6–8 cm thick was poured. waves.

Backfill without clay-sand lubrication was assumed to be at least 80 mm thick. Logs were laid on top of it, to which a floor was nailed from tongue-and-groove boards, attached with nails to the logs, from plates or boards that were laid across the beams every 500-700 mm.

From below, a filing of thin boards 12–18 mm thick is nailed to the beams. As a reel, you can use single-layer boards made of bakelized plywood, boards and other sheet materials that can withstand the weight of the backfill, etc.

The beams themselves are made of coniferous wood, and the cranial bars, in addition, are made of alder and aspen wood.

The most optimal spans for wooden beams were considered spans up to 4 m, but in housing of the II group of capitality, wooden beams were also used for large spans (up to 6 m).

Beams are most often rectangular wooden beams. The height of the beam depends on the span and is its length. The width of the tank depends on its height. The beam size ratio is 7:5.

The main load-bearing elements of a wooden beam ceiling are rectangular wooden beams 140-240 mm high and 50-160 mm thick, laid through 0.6; 0.8; 1 m. The cross section of the wooden floor beams was taken depending on the load, filing (rolling) with backfill, and the plank floor laid on the logs as directly on the logs.

Minimum section of wooden beams of a rectangular floor

|

Width |

Distance between beams, m |

||||||

|

0,5 |

1 |

||||||

|

KPa (kgf/m²) |

|||||||

|

1,5 (150) |

2,5 (250) |

3,5 (350) |

4,5 (450) |

1,5 (150) |

2,5 (250) |

3,5 (350) |

|

|

2,0 |

5 x 8 |

5 x 10 |

5 x 11 |

5 x 12 |

10 x 10 |

10 x 10 |

10 x 11 |

|

2,5 |

5 x 10 |

5 x 12 |

5 x 13 |

5 x 15 |

10 x 10 |

10 x 12 |

10 x 13 |

|

3,0 |

5 x 12 |

5 x 14 |

5 x 16 |

5 x 18 |

10 x 12 |

10 x 14 |

10 x 15 |

|

3,5 |

5 x 14 |

5 x 16 |

5 x 18 |

10 x 16 |

10 x 14 |

10 x 16 |

10 x 18 |

|

4,0 |

5 x 16 |

5 x 18 |

10 x 17 |

10 x 18 |

10 x 16 |

10 x 19 |

10 x 21 |

|

4,5 |

5 x 18 |

10 x 17 |

10 x 19 |

10 x 20 |

10 x 18 |

10 x 21 |

10 x 23 |

|

10 x 16 |

10 x 19 |

10 x 21 |

10 x 23 |

10 x 20 |

10 x 23 |

10 x 26 |

|

The use of hardwoods as floor beams is unacceptable, as they do not work well in bending. Therefore, as a material for the manufacture of wooden floor beams, coniferous wood is used, peeled from bark and antiseptic in without fail. Most often, the ends of the beams are inserted into nests specially left for this purpose in brick walls ah directly during the masonry process, or cut into the upper crown of log, block and frame-panel walls.

Beams for flooring were usually made of round timber, processed into four edges, timber or boards with a thickness of 60–80 mm, mounted on an edge. Paired boards 50 mm thick were also used, which were “sewn” together with nails or metal staples. With large spans, the middle part of the beams was supported by internal walls or intermediate pillars.

For the manufacture of beams (logs), pine, spruce, larch wood was used, with a moisture content of not more than 14 percent (with proper storage, wood acquired such moisture in a year). The drier the beam, the stronger it is and the less it sags from the load.

So that the interfloor beams do not sag, they were laid at a distance of no more than a meter from each other, or even closer. Already at the beginning of the XVIII century. it was known that the most bending beam is a beam with an aspect ratio of 7: 5. A round log is stronger than a hewn beam, since the hardest layers of wood are adjacent directly to the bark. However, it was less resistant to bending, cracked under load, and the round section was untechnological in nodal joints.

To ensure the rigidity of the beams, it is necessary to lay them at a distance of up to about 1.2 m from each other. When laying the floor, the edge beams must not be laid so that they are in contact with the wall. Between them it is necessary to arrange a gap about 30 mm wide. The beams rest on load-bearing walls, deepening the ends by 150 - 200 mm (Fig. 2).

When embedding wooden beams in the nests of brick walls, it is recommended that the ends of the beams be treated with bitumen and dried to reduce the likelihood of rotting from moisture. The ends of the beams must be left open. Spatial niches when sealing wooden floor beams are filled around the beam with effective insulation ( mineral wool, Styrofoam). With a brick wall thickness of up to 2 bricks, the gaps between the ends of the beams and the brick wall were filled with cement mortar. In addition, the ends of the beams, previously coated with resin, were insulated with wooden boxes.

In brick walls, the ends of the beams were not covered, leaving ventilation holes. This protected the ends of the beams from moisture condensation. Wooden floor beams rested on the load-bearing walls in open nests, closing them up by 150 mm. The supporting ends of the beams, most often, were wrapped in two layers of roofing paper to prevent their decay.

During operation due to condensation warm air, penetrating from the house, with cold, located in nests - the ends of the beams of interfloor and attic floors in stone buildings often rotted in nests specially made to support them. Therefore, since the mid-1950s, for apartment buildings of the III capital group, nests in brick walls were made somewhat larger than the ends of the beams. The lower part of the nest must be dry; to level it and prevent decay, it was laid with canvas soaked in tar. The depth of the nest in stone buildings was usually 250 mm, and the ends of the beams were brought into the masonry by at least 150 mm.

Every third beam embedded in outer wall, fixed with a T-shaped anchor - to create a kind of horizontal stiffening disk in the floor area. Anchors were attached to the beams from the sides or from below and embedded in the brickwork. The height of such a beam was assumed to be 200 mm, width 100 mm. The length of the supporting ends of the embedment of the beam was at least 15 cm.

In the absence of a beam of a suitable section, boards knocked together and placed on the edge can be used, while the total cross section, in comparison with the whole beam, should not decrease.

Roll-up shields rested on cranial bars with a section of 50 × 50 mm, nailed to the side faces of the beams. A backfill of slag was arranged on top of the roll, and a filing of thin boards 12 mm thick was nailed to the bottom of the beams.

|

|

|

|

termination wooden floor beams into the outer wall: 1 - wall, 2 - lining, 3 - embedded end of the beam. |

termination wooden floor beam into a brick wall: 1 - a brick wall, 2 - a wooden beam, 3 - the end of the beam, treated with antiseptic paste or wrapped with roofing material, 4 - waterproofing from two layers of roofing material. |

Laying beams led in the "beacon" way, first installing the extreme beams, and then the intermediate ones. The correctness of the position of the extreme beams was checked by a level or spirit level, and the intermediate ones - by a rail and a template. The beams were leveled by placing tarred scraps of boards of different thicknesses under their ends. It is not recommended to lay chips or trim the ends of the beams.

Wooden floor beams were laid, as a rule, along a short section of the span, as parallel as possible to each other and with the same distance between them. Taking into account all the above, the ends of the beams, resting on the outer walls, were cut obliquely at an angle of 60 degrees, antiseptic, burned or wrapped with two layers of roofing felt or roofing material. When sealing wooden beams into the nests of brick walls, the ends of the beams were treated with bitumen and dried to reduce the likelihood of rotting from moisture. The ends of the beams were left open. Spatial niches, when sealing wooden floor beams, were filled around the beam with insulation, for example, wooden boxes, having previously tarred them.

When supporting beams on internal load-bearing walls, two layers of roofing felt or roofing material are placed under their ends.

In the enclosing structures, the ends of the beams were not covered, leaving ventilation holes. This protected the ends of the beams from moisture condensation.

Instead of block beams, logs of the appropriate diameter, hewn on three sides, were also used, which is more economical (roundwood is much cheaper than lumber), but in this case the logs must be aged in a dry room for at least one year, like a log cabin.

To enhance the bearing capacity of the ceiling, a cross scheme for installing power beams was used. When applying such a scheme, the floor rests on all the walls of the building along the contour. The nodes of the intersections of the beams were pulled together with clamps or wire twists. The cross-section of floors in housing of the III capital group is quite rare, only for square structures in terms of structures, since it was much easier to reduce the step of the supporting beams and make an ordinary floor, although less lumber was spent on the manufacture of the cross-floor than on the traditional one, with the same carrier covering abilities.

Structural differences in floors in housing of the III capital group are observed in the way they are insulated. The interfloor overlap, as a rule, was almost not insulated, the attic (with a cold attic) was insulated with the installation of a lower vapor barrier layer, and the basement was insulated with an upper vapor barrier layer.

For its fastening of the rolling flooring, cranial bars with a section of 5 x 5 cm were nailed to the beams, directly onto which the rolling boards are laid. The reel plates were tightly fitted to each other in order to remove all the gaps between the individual boards. The lower surface of the roll should be in the same plane with the floor beams. For this, a quarter (fold) was selected in the boards. For the construction of the reel, full-fledged boards were not always used, most often they were replaced with a croaker. The lining of boards 20-25 mm thick was fastened with nails hammered at an angle.

The laid roll was covered with a layer of roofing felt or roofing material and covered with insulation. Loose heaters were not rammed. The type of insulation and its thickness were determined by the calculated outdoor air temperature.

The thickness of the backfill of the attic floor, depending on the outside temperature

|

Material |

Volume weight, kg/m³ |

Backfill thickness (mm) at |

||

|

sawdust |

||||

|

Wood shavings |

||||

|

Agloporite |

||||

|

Boiler slag |

1000 |

|||

Lastly, the upper face of the beams was covered with roofing felt or roofing material, and logs were laid on top if the beams had a rare arrangement.

At the same time, no filing was used in the basement floor, and logs and a clean floor were used in the attic floor.

The basement was designed in such a way that, without prejudice to performance, not to use rolling and insulation in its manufacture (of course. In this case, a roofing material was used over the entire floor area, and gravel or compacted crushed stone was used as a backfill.

Since initially housing of the III capital group was designed with stove heating, cutting was arranged at the points of contact of wooden floors with smoke channels - thickening of the pipe walls. The distance from the edge of the smoke channel to the nearest wooden structure was assumed to be at least 380 mm. Ceiling openings in the places where chimneys pass were sheathed with fireproof materials.

Within the cutting limits, the wall thickness of the chimney increased to 1 brick, that is, up to 25 cm. But even in this case, the floor beams should not touch brickwork pipes and stand at least 35 cm from the hot surface. This distance could be reduced to 30 cm by laying felt or asbestos cardboard 3 mm thick between the groove and the beam soaked in a clay solution. The end of a shortened beam, located opposite the groove, rested on a crossbar suspended on clamps from two adjacent beams.

The floor was considered economical, consisting of wooden panels with one-sided and two-sided sheathing, which, together with the frame of the shields, perceives vertical loads. Sheathing is a bearing element of the floor if it is firmly connected to the edges of the boards of the shield frame. The ribs and skins are tightly connected to each other and have a high load-bearing capacity.

At the end of the 50s, bakilized construction plywood was used as cladding, which showed high performance. Boards, due to the large number of equally oriented seams, do not contribute to an increase in the bearing capacity of the floor.

For single- and double-span structures, when the calculated values were exceeded, additional supports were brought under the ceiling, which significantly increased the cost of the structure.

For a single-span ceiling, where the shields were supported only at the ends of the stiffeners, the span width, which somewhat exceeded the clear width of the room, should not exceed 5 m. For a double-span floor, the allowable span width and, accordingly, the room increased to 6 m.

floors in the type of structures under consideration, they had manufacturing features only on the first floor of buildings without basements and underground. The wooden plank floors of the first floor were arranged on the planned ground with the addition of sand - on brick columns. Wooden logs rested on the posts, along which a plank floor was laid. Brick columns along the logs were covered with insulation.

As a result, it turned out to be economically profitable, but rather cold during the period heating season design.

stairs serve to communicate between floors, as well as the evacuation of people from the building. They consist of marches, landings and railings with railings. Landings at the level of each floor are called storey, and landings between floors are called intermediate. The march is a structure consisting of steps and beams supporting them. The beams located under the steps are called stringers, and the beams to which the steps adjoin from the side are called bowstrings. The vertical edge of the step is called the riser, and the horizontal one is called the tread. The steps most often had a height of 150 mm and a width of 300 mm. These dimensions made it possible to arrange the slope of the march in a ratio of 1: 2. The width of the stairs was taken at least 1,200 mm, the width of the platforms was not less than the width of the march. The number of steps in one march ranged from 5 to 18. In stone temple houses, wooden stairs were richly decorated with carved wooden columns, and the fence - with intricate balusters.

stairs serve to communicate between floors, as well as the evacuation of people from the building. They consist of marches, landings and railings with railings. Landings at the level of each floor are called storey, and landings between floors are called intermediate. The march is a structure consisting of steps and beams supporting them. The beams located under the steps are called stringers, and the beams to which the steps adjoin from the side are called bowstrings. The vertical edge of the step is called the riser, and the horizontal one is called the tread. The steps most often had a height of 150 mm and a width of 300 mm. These dimensions made it possible to arrange the slope of the march in a ratio of 1: 2. The width of the stairs was taken at least 1,200 mm, the width of the platforms was not less than the width of the march. The number of steps in one march ranged from 5 to 18. In stone temple houses, wooden stairs were richly decorated with carved wooden columns, and the fence - with intricate balusters.

Platform beams and bowstrings 60–80 mm thick served as load-bearing elements of wooden stairs. To connect the steps with the bowstrings, grooves were selected along the side surface of the bowstrings, into which the ends of the boards of treads and risers were inserted. From below, the marches had a plank filing, which was sometimes plastered.

In residential buildings in the Ordinary capital group, two types of wooden stairs were used: two-flight and three-flight. The width of the march is 1.2 m, the height of the march is 1.5 m. The height of the riser is 150 mm, the width of the tread is 300 mm.

Landing node: 1 - backfill; 2 - only; 3 - filing; 4 - plaster; 5 - bar; 6 - crossbar