Do-it-yourself metal roof repair. Do-it-yourself roof repair

Roof repair is not the easiest thing, but still quite feasible, if you follow certain rules and have some skills. It should be noted that it is far from always necessary to change the roof completely, when at first glance it is completely worn out. Sometimes it is enough to make a partial repair of the roof. The more years the roofing, the more effort, time and materials will be required to repair it. However, after that, you can count on the fact that the roof will protect the house from external influences for many more decades.

Roof repair depending on the roofing material

It should be noted that roof repairs are carried out in completely different ways, depending on which material is chosen for the roof. Today, the construction market can offer a huge amount of materials for these purposes.

- Slate roof repair.

Almost anyone with certain skills can handle it. As practice shows, people whose roof is covered with slate most often encounter problems such as small chips and cracks. To eliminate them, you can use a cement mortar. It can be prepared quite easily by mixing 1 part cement and 2 parts fine sand.

Currently, there are also special adhesive tapes, which include butyl rubber. With the help of such tapes, also without special work small cracks in the slate roof can be dealt with. You just need to remove the protective film from the tape and stick it on the crack. Experts recommend using large pieces of tape (at least 4 cm). Such devices are very convenient, since on the one hand they can be painted in any color. Important Rule, which must be taken into account, before sticking the tape, the surface to be treated should be wiped with a cotton cloth soaked in gasoline.

Restoration of a slate roof also involves coating the nails that hold the slate together with drying oil. This procedure is performed to protect them from snow and rain.

During such repairs, do not forget that the slate is quite fragile. That is why you need to move along it with extreme caution. It is better for these purposes to resort to the help of a ladder-ladder.

- Roof from a metal tile.

Homeowners whose roofs are covered with metal tiles often face problems such as loose fasteners, leaks resulting from roof installation errors, and mechanical damage that can occur during inaccurate de-icing of the roof. The problems described above can be dealt with by sealing the distance between the metal tile and the grooved material. For these purposes, the same adhesive tape can be used. If there are many scratches, then they must be covered with paint that protects against corrosion. Steel patches must be applied to all through holes. This is very easy to do with a regular soldering iron. Advice from professionals: if there are a large number of holes on the metal tile, then it would be wiser to change the entire sheet.

Often, homeowners are faced with the fact that self-tapping screws fail. Such problems can occur as early as 1-2 years after the installation of the roof. Faulty self-tapping screws should be replaced with new ones, but from a better material.

Back to index

What else can you fix yourself?

In addition, you can do the repair of metal sheet roofing with your own hands. Such a coating most often needs to be repaired due to a violation of the integrity of the seams that hold its sheets together. The integrity of the seams is destroyed due to corrosion and damage.

You can fix the annoying problem with the help of the following manipulations:

- First you need to thoroughly clean the bad sheets with a metal brush.

- After that, a patch must be cut out of the metal sheet (its dimensions must exceed the size of the area of the affected area).

- Next, you need to process the damage site and the patch itself. For these purposes, it is necessary to use an alloy of lead and zinc. The processed patch with the help of a powerful soldering iron must be soldered to the roof surface.

- After cooling, excess solder should be removed with a file.

- It remains only to cover the roof with paint.

Often the roofs of a private house are covered with shingles.

This material boasts a huge number of advantages. However, like any other roofing material, shingles may fail. It should be noted that such material is very easy to leak.

First you need to get rid of the old nails. After that, you need to carefully pull out the damaged tiles and replace them with new ones. You can fasten the tiles with long 25 cm nails (the nails must have a wide hat).

It should be noted that the owners of such houses are most often found with gaps on the roof that occur at the junction. You can cope with such gaps if you resort to the help of bituminous mastic (you should carefully grease all the gaps with it).

Back to index

Rafter system repair

A complete repair of the roof truss system is required only when more than 50% of the roof has been affected by rot. Everything can be fixed by replacing those areas that are damaged for any reason.

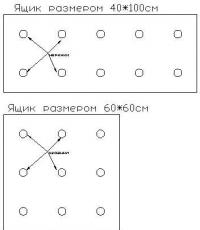

In cases where the rafter leg is not completely affected, wooden lining should be used. All work is carried out in several stages. If the rafter is broken, then you can deal with the problem by placing a board on the floor of the attic and placing a jack on it. After that, it is necessary to install overlays on the damaged rafter from 2 sides. Their thickness should not be more than 4 cm, and the length - 100 cm. The linings are nailed to the rafters. On each side, 4 small holes are made into which mounting bolts are inserted. After that, the bolts should be properly tightened.

If most of the truss system was affected, then do-it-yourself roof repairs are carried out in a different way. In case of massive damage, experts advise using bar prostheses. To change the rotten parts of the rafter leg, you need to go through several stages.

To begin with, on the damaged area, the crate and roof should be completely disassembled. After that, it is necessary to proceed with the installation of the rack for temporary fastening of the rafter leg. Next, a rotten section of the structure is sawn out, on rafter leg put on the prosthesis and lay it on the Mauerlat. To prevent slipping, the sawn end must rest against the support platform. It remains only to disassemble the temporary racks. They are disassembled only after the reliability of the design has been verified.

Slate has always been considered one of the most popular roofing materials of all. This is easily explained - it is affordable for everyone, simple and understandable in installation, unpretentious in maintenance, strong and durable enough. Therefore, the vast majority of private houses in Russia, despite the diversity of more modern materials, yet has

However, with all the positive qualities of this material, despite the strength of the asbestos fibers that make it up in combination with cement filling, slate sheets cannot “boast” of high resistance to accentuated mechanical loads, and natural exposure is slowly “aging” them. Therefore, over time, cracks or even serious holes can form on the roofing, as a result of which the roof will begin to leak. Replacing an entire roof covering is an expensive and time-consuming undertaking, which is why many homeowners resort to renovations.

Repair of slate: how to close holes and cracks - this is how the question is often raised by homeowners if there are obvious signs of a roof leaking. To choose the right, optimally suited for a particular case, the method of putting the roof in order, you need to consider some of the most popular technological methods. This is what this publication is about.

The main reasons for the destruction of slate

Slate is attractive because this material has clear advantages over other coatings. For example, such a roof, unlike steel coatings, is not subject to corrosion, is highly resistant to moisture, tolerates temperature changes well, practically does not give significant linear expansion, and is almost completely indifferent to the influence of ultraviolet rays. However, it still needs to be repaired from time to time.

Slate is still not eternal - it decays, becomes covered with cracks, chips can form along the edgesBefore proceeding to the description of technological methods for performing repair work, it is necessary for clarity to determine the possible reasons occurrence of flaws. With this information, it is quite possible that it will be possible to prevent such damage simply by paying attention to the prevention and proper care of the slate.

So, on the slate may appear for the following reasons:

- Most often, these are some kind of shock loads, for example, a large hail or large tree branches falling onto the roof surface. This also includes inaccurate, incorrect movement on the roof surface.

In order not to damage the slate during roofing or repair work, it is necessary to secure it by laying a flooring of boards on top, which will increase the supporting area and thereby reduce the pressure on the coating.

For roofing or repair work on slopes of great steepness, over 20 ÷ 25 °, especially in the area or upper part of a slate roof, it is necessary to have a special mobile ladder, which is fixed by a special mount by the ridge.

- The second reason is the appearance and development on the surface of the slate of colonies of the simplest plants, which are fixed on it, and slowly but steadily destroy the structure of the material. Lichens and mosses especially love the rough surface of the roof. Having fixed in one place, they first grow in size, and then multiply by spores and over the entire surface of the roof. Moss grows into the joints of slate sheets and thereby begins to lift them, which is why during rain water is able to freely fall under the coating. If the moss has chosen a place at the bottom of the wave, then it can delay the normal flow of water, which also leads to the roof leaking.

These phenomena usually occur on the north side of the roof, where the sun is not enough time, or on the roof, which has a slight slope, due to which moisture is retained on it, contributing to the growth of such plant colonies. In addition to the fact that the coating is destroyed and the roof begins to leak, the whole building as a whole looks sloppy and not aesthetically pleasing.

If mossy colonies have already settled on the roof, but there is a desire to try to save the roof, avoiding its replacement, then it is necessary to free the slate from this "garden". This process can be done in three ways:

- mechanical, using an iron brush;

- using water high pressure;

- chemical, by spraying the roof with special herbicidal compounds.

- The reason for the dilapidation of slate can be quite a banal reason - a long service life. Unfortunately, not all slate produced today is of the proper quality, since often in its manufacture, in order to reduce production costs, not only GOSTs, but even less “demanding” specifications are not fully observed. As a result, the sheets of such a slate coating turn out to be brittle, and, not withstanding even minor blows, crack or even split along the entire length. Non-compliance with technological rules can be allowed at various stages of the slate production process, for example:

- The solution for the manufacture of slate was made in violation of the recipe - the proportions of the constituent ingredients were not observed.

— Roofing material produced on handicraft equipment.

- Insufficient quality processing of slate sheets.

- Reduction of the period of full maturation of the material - it must be at least 28 ÷ 30 days from the date of manufacture.

Unfortunately, it has been noticed that products of the "old school" serve for more than a dozen years, and modern slate is often only enough for 12-15 years. Conclusion - when buying a material, you should pay increased attention to the reputation of the manufacturer and the obligations provided by him.

- From stagnant water around chimney and ventilation pipes, as well as skylights, cracking of sheets of material can also occur, especially with a sharp drop in temperature. Therefore, such problem areas require enhanced sealing and ensuring the free flow of water.

- As mentioned above, a slight slope of the roof slope and stagnation of water on it can also contribute to the cracking of the material. And stagnant water very often becomes the result of a banal accumulation of dirt or fallen leaves, that is, a kind of damming of the waves.

- The reason for the damage may also be that the installation of slate sheets was carried out in violation of the established technology of this process, and this may cause the coating to experience excessive internal stresses.

- To fix the material to the crate, ordinary nails were used or rubber gaskets were not used. In this case, cracks will certainly appear over time.

- Too small holes were drilled for driving slate nails, which, if the temperature changes and the material expands, will also lead to damage to the coating sheets. Therefore, when drilling holes, it must be borne in mind that slate nails must enter them freely. But, at the same time, the holes should not be too large, otherwise leaks will occur.

- Snow also adds load to the roof, and not only with its considerable weight, but also with the formation of ice in the lower part of the slope, near the eaves. AT spring days or during the thaw period, the snow begins to thaw, and water flows into the lower part of the slope, and in the evening the air temperature drops, and ice forms on the edge of the slate, which leads to crumbling of the roofing material in this area.

If the slate in this place is destroyed, then through the cracks formed, water will fall on the crate, insulation, rafters and mauerlat, on bearing walls, which will lead to the formation of fungus and the gradual decomposition of wood. Therefore, prudent homeowners, in order to preserve all the materials and elements of the roof, often arrange cable heating in the lower part of the slope and in the drainage channels, which in winter period if necessary, it turns on, preventing the formation of frost

Now, having considered the main causes of slate damage, taking into account what possibilities exist to avoid them, let us dwell on how to identify damage that has appeared.

Detection of roofing defects

On the rough surface of slate laid on truss system, it is almost impossible to see small chips or microscopic cracks, therefore, special attention should be paid to some alarming signs that the roof needs repair:

- If there is at least a small leak, even imperceptible to the eye, then soon it will manifest itself by the appearance of mold spots in the corners or at the joints of the ceiling and walls, the occurrence bad smell dampness.

- If thermal insulation material is not fixed on the roof from the inside, then even the smallest crack is easy to detect by climbing up to the attic after rain. The leak will show itself as a darker spot compared to the rest of the inner surface.

Now you need to focus on which areas of the roof most often need to be repaired, as this information will come in handy when looking for damage to the roofing.

- First of all, it is necessary to monitor the edges of the slate that go to the eaves. They are recommended to be examined every spring. If cracks have formed on the edges, then they will not be difficult to detect - sometimes you don’t even have to climb the stairs for this, as they can be seen from below.

- Moss may appear on the roof without cracks or chips, but you should not wait until it grows and occupies the entire surface of the slate. It is on a neglected roof after cleaning that a very sad picture with a lot of damage is very often found. In addition, it is much easier and cheaper to remove several islands of emerging moss than to subsequently clean the entire wavy surface.

- Cracks can form at the crest of a wave or at its lowest point. It is more difficult to detect the latter, since they are invisible at first glance. How they can be identified has been described above.

- On the crest of a wave, the cracks are mainly formed along the line where the slate nails are driven in, and they are immediately visible to the naked eye. However, if these cracks are already so evident that they are visible visually, repairs should be urgently started.

Having examined the roof in all respects, it is necessary to make a decision on how it will be more rational to carry out repairs.

- If significant chips are found along the edge of the lower sheets, then one or all sheets of the first row should probably be replaced, especially since the roof structure allows this to be done. However, it must be taken into account that the nails will have to be removed with all care so as not to damage the bottom edge of the next row, since it is he who overlaps from above to the bottom.

If it is not possible to replace the sheets, then the integrity of the edge can be achieved by putting a kind of patch on the inside of the sheet, but it is impossible to leave the coating in a damaged state, since in this case leaks cannot be avoided.

- If the crack went along the crest of the slate wave, then it must be repaired with patches by applying them from the inside and outside. Usually, a piece of galvanized iron sheet bent in the shape of a wave is placed under such a crack from the inside, and a special roofing tape is applied on top of the damage.

- If the crack has gone across the slate sheet, then you can’t do without replacing it. You will have to carefully dismantle it and install a new one.

Methods of repair work on sealing damaged areas of slate

So, knowing all the nuances of the occurrence of defects in this roofing material and the detection of damage on it, it is necessary to proceed to the consideration of repair work.

There are several effective ways sealing cracks using traditional and special modern materials. But in any case, all repair work must be carried out on the roof surface, well cleaned of dirt, debris, any growths, foreign objects etc.

Whatever approach is chosen for repair work, one should never forget to carefully move along the slate if the damage was found not at the edge of the roof, but at a height. To avoid additional damage to the slate on gable roof they use a ladder-ladder, and on a shed - flooring from boards that will help to evenly distribute the weight of a person on the surface.

The first way - using ordinary concrete mortar

Repairing slate with cement and sand can be called the simplest and most accessible way, if you do not take into account that the process will take place at a height - this always complicates the work.

The solution for repairing slate is made from cement and sand in proportions of 1: 2, and fine-grained washed sand and cement grade M-500 are used for it. Instead of this solution, it is quite possible to use high-quality tile adhesive for external facade works(you can also find another name - for complex bases), able to withstand high humidity and temperature extremes. The glue has a fine consistency and good adhesion to the surface of the slate, as it is also made on a cement basis.

The solution should have the consistency of a soft dough and adhere well to the surface. To increase the adhesion of materials, the slate in the repair area should be moistened. If the damage is too large, then a lining of galvanized roofing steel should be made under it, bending a piece of sheet in the shape of a wave and slipping it under a crack or pothole. This device will give an additional guarantee of a good fit of the solution to the asbestos concrete surface.

The solution is applied to the surface with a spatula. On the surface there should be a not too thick layer of it, which will not hold water much if the crack is in the bottom of the wave. The surface of the applied solution should be even - for this it is slightly moistened and smoothed with a hand in a rubber glove.

After the final drying of the patch, it should be carefully primed, and then painted with a waterproof slate paint for outdoor use.

The second way - using butyl rubber sealing tape

Butyl rubber waterproof tape is used not only for repair work, but also for sealing the joints between sheets, as well as for waterproofing the fit of the roofing to ventilation and chimneys.

The surface of the tape is made of non-woven material, thanks to which the applied patch can be coated with paint of the desired color. Working with such material is quite simple, and repairs are carried out in the following sequence:

- The slate area requiring repair must be cleaned and degreased. This can be done with white spirit, acetone or other organic solvents.

- Further, a piece of tape of the required length is cut off from the roll (so that the entire crack is closed, plus along its edges the tape enters the undamaged area by another 50 mm).

- The adhesive layer of the tape is covered with a protective film. The tape is applied to the crack and, in the course of its gluing, this protective substrate is removed from it sequentially, very carefully. There is no need to hurry - you can not allow wrinkling, wrinkling, sticking of the tape.

- The tape is carefully pressed against the surface of the sheet, as it should fit as tightly as possible, without the slightest gaps, to the slate.

- So that the patches do not stand out on the roof, the roof can be completely covered with paint or you can choose a shade to match the patch to match the slate. But painting over the patches on top with high-quality waterproof paint is a must.

It should be noted that not rolls can be found on sale, but ready-made butyl rubber patches of various sizes.

In addition, for a more reliable repair of wide cracks in the slate, in addition to butyl patches, it is recommended to use fiberglass, which acts as a reinforcing layer that gives greater strength to the sealed seam.

If work is carried out using a sickle, then for the bottom layer glued to the damage, use a double-sided tape or patch, that is, a coating with a protective substrate on both sides. In this case, the work is carried out in the following sequence:

- Butyl tape is first glued onto the fat-free slate, in the same way as it was shown above - only the bottom substrate is carefully removed. The tape is also carefully smoothed over the repaired area.

- Then the top protective coating is removed from it.

- After that, a cut-out piece of sickle tape is fixed on top of the tape.

- Then, a tape is fixed on the serpyanka with one-sided application of an adhesive composition and a non-woven surface on the front side.

- The last step is coloring.

The third way - using bituminous mastics

Repair with the help can be carried out in two ways - hot and cold.

bituminous mastic

1. If repair work is carried out with hot bitumen, then it must first be prepared - this is done as follows:

- Bitumen is put into the old bucket.

- A fire is kindled, which is fenced with bricks so that a bucket of bitumen can be placed on them.

- The contents of the bucket are periodically stirred so that it does not burn to the bottom or ignite. The composition must be heated to 160 degrees.

- If the work will be carried out at a negative temperature outside, then it is recommended to add about 10% of oil waste from the total volume to the bitumen. It will give the composition the missing elasticity, which will help to avoid cracking the patch. This is especially important if the edge of the roof is being repaired, as this area is considered the most problematic. In this case, it is best to additionally reinforce the patch with fiberglass mesh.

- You can do without reinforcement if you stick it on hot bitumen waterproofing material type "TechnoNIKOL" ("euroroofing material"), which is usually used to cover flat roofs.

Due to the elasticity of the material, it will perfectly take the shape of slate waves. If it is not possible to press it tightly against the applied mastic, then it will have to be heated with a burner or a building hair dryer.

Bitumen is applied to the degreased damaged area of the roof with a brush or spatula. Then reinforcement is laid on the heated mass. After the first bitumen layer has set, another bituminous layer is applied on top of the sickle mesh.

2. When using ready-made waterproofing bituminous mastic, its heating is not required.

It will be enough to mix the contents well and apply on a previously degreased and primed slate surface.

On the first layer of mastic, you can also lay a sickle mesh, which additionally fastens the two edges of the sheet, which were separated by a crack.

The number of layers can be any, but the thicker it is, the longer the period of its drying. Therefore, the most the best option it is considered as follows: two layers of mastic 1.5 mm thick, between which reinforcing material will be laid.

The fourth method - using cement-asbestos mortar

Repair of slate in a similar way is carried out using a mixture of cement with the addition of asbestos fibers and PVA glue. Bulk asbestos can be made by grinding a piece of asbestos sheet, cord or strips that are used in masonry brick ovens. When grinding this material, it is imperative to secure Airways a respirator or at least a medical mask, and protect your eyes with goggles.

For the manufacture of the mixture, materials are taken in the following proportions: 3 parts of asbestos, 2 parts of cement, and PVA glue and water are diluted 1: 1. All components are mixed until the mixture reaches the consistency of thick sour cream. The composition is prepared immediately before its use.

Slate for applying this composition must be well cleaned and dried. After it dries, the damaged area of \u200b\u200bthe sheet is carefully primed with a solution consisting of PVA and water, taken in a ratio of 1: 3. Such a primer is applied in two layers, waiting for each of them to dry.

Then, using a spatula, the asbestos-cement composition is applied to the damaged area of \u200b\u200bslate treated with a primer. If a crack is closed in the lower part of the wave, then the layer should be as thin as possible, approximately 1 ÷ 1.5 mm. In the case when the defect is located on the crest, the layer thickness is of no fundamental importance. In the latter case, it is very important to fill the resulting crack throughout the entire thickness of the slate. The applied material must be well leveled, since its surface must be smooth.

Fifth way - using polyurethane foam and epoxy resin

We can say that this method was invented by home craftsmen, since repairs are carried out using mounting foam and epoxy. To perform work using these materials, you will need a balloon of mounting foam, a sealant and a two-component epoxy adhesive complex, the latter will serve as a waterproofing for the foam. This method is called "three-layer", and the repair itself is carried out in several stages:

- The preparatory stage consists in cleaning and degreasing the repaired area. If the crack or gap in the slate is large enough, the edges of the slate inside this hole should be cleaned and processed using, for example, a file.

- The next step is to fill the existing gap (hole) mounting foam. After that, you should wait for a pause necessary for the expansion and polymerization of the foam, about a day. It should also be noted here that if a very large flaw has formed in the slate, then it is recommended to place a piece of roofing material or galvanized metal under it, but it must be well pressed from below to the slate, otherwise the foam, expanding, will push it away.

- After the foam dries, its excess is cut off in a waveform.

- On top of the hardened and cut foam, a sealant is applied in a thin layer. It is necessary to ensure that it fills all the pores on the surface of the material. After that, the sealant is left to dry completely. The curing and hardening time of the sealant, which must be allowed to pass before proceeding to further operations, is usually indicated on the packaging of the material.

- The third, final stage is the coating of the repaired surface with an epoxy composition, which will finally smooth the surface and it will merge into a single whole with the slate. The cured epoxy will cover the repair patch with a durable protective layer.

This repair method is quite complicated and expensive. But after complete hardening of the repaired area, it gains high strength and is guaranteed to eliminate the problem of roof leaks.

If you need to repair a slate sheet located in the middle of the slope and split along the entire length, then you can get by with only an epoxy composition, which fills the entire crack completely. In this case, first, from the bottom side of the sheet, from the side of the attic, a mounting waterproof tape is glued onto the crack, and only after that the gap is completely, as tightly as possible, filled with epoxy.

The sixth way - chalk + drying oil

This composition for repairing cracks in slate can also be called folk, however, it is absolutely not suitable for sealing large holes, therefore, if such a technique has formed, then such a technique can be immediately rejected.

The repair mixture in this case is made from chalk and drying oil. The mixture should eventually resemble the consistency of thick honey. Therefore, chalk is added to the drying oil, so to speak, “by eye”, in small portions, each of which is thoroughly mixed. The mixing process is carried out until the desired density of the solution is reached.

The finished mixture is covered with a pre-cleaned crack, and then leveled. After the mixture dries, the crack is densely covered with moisture-proof paint. On this, work on repairing slate in a similar way can be considered completed.

The seventh way is to use moisture-resistant nitro-based glue

In this method of repairing roofing material, a moisture-resistant nitrocellulose adhesive is used, for example, "Emalit". The defect is repaired as follows:

- Inner side slate sheet, leaving in the attic, is well cleaned with a metal brush and washed with water, then completely dried.

- Dry slate in places of damage is sealed with a cloth. To do this, you can use a regular thick cloth or fiberglass. The patch should have a size that exceeds the size of the hole or crack by 40 ÷ 50 mm on each side.

- The fabric is impregnated with glue and superimposed on the damaged area, well pressed and smoothed.

- After the materials have been bonded and the glue has set, another glue is applied on top of the patch.

- After the internal patch is fully prepared, on the outside of the sheet, the hole or crack is filled with concrete mortar or tile adhesive for facade work. The surface of the filled hole must be well leveled.

- If a crack is closed, then one hole is drilled at its beginning and end, which are filled with an elastic sealant, and then self-tapping screws are screwed into them. This must be done so that the crack does not develop further.

The eighth method - using special waterproofing coating compositions

Excellent for repairing slate sheets are ready-made cement-polymer-based waterproofing coatings, sold ready-made in buckets, or in the form of dry mixes that require dilution. Instructions for their preparation can always be found on the packaging.

In any case, it is very easy to work with such compositions, since they have a fine-grained composition that fits perfectly on the repaired material due to its high adhesive qualities. Repair work is carried out in the following order:

- The surface around the damage, cleaned and degreased with the help of one of the solvents, as well as the inner walls of the crack, are dried well.

- Then, the waterproofing mixture is diluted with water, and the surface to be repaired is primed with it. The primer should also dry well.

- The next step is to apply a thick mixture prepared for repair using a spatula or gun.

- After six hours, the crack must be covered with fiberglass, and on top of this patch, apply another layer of waterproofing compound and level it well.

If a certain repair method is chosen, it would be wise to inquire about the weather forecast for the coming days for which work is planned. Repair of the roof should be carried out in dry, calm, but better - not sunny, cloudy weather, since any mixture should dry out at medium temperatures. Therefore, the best time for repair work will be the end of summer or the beginning of autumn, when it is quite possible to choose the days that are suitable for the forecasts.

In addition, it must be remembered that even very good and high-quality patches will only provide temporary protection against roof leakage. The problem is that the roofing material and various repair compounds have different linear expansion coefficients and densities. Therefore, sealed flaws can only withstand a few cycles of strong temperature changes, and then leaks will appear again. Such repairs are needed so that homeowners have time to select and purchase new roofing. If it is possible to close the roof immediately, then if serious damage occurs, you should not resort to repairing it - it is better to immediately resolve the issue radically.

Protecting the slate from further damage

If on a roof that has been in use for a long time, cracks have appeared from time to time, then patching or filling the damage with sealant will not be enough, since the destruction will continue anyway. In this case, in addition to completely replacing the coating with a new one, there are several more ways to stop the process of rapid aging of the slate roof.

- First of all, the roof surface is well cleaned, washed and dried. If there are no moss growths on the slate, then the coating can simply be cleaned well with a broom. In any case, whatever cleaning is carried out, the airways of the master during this operation must be well protected - asbestos dust is extremely harmful.

- Further, it is recommended that the entire surface of the roof be well primed and dried.

- Further, the slate roof is completely covered with rubber paint, which creates an elastic waterproofing layer on the surface.

- Another way to save an aging slate roof is to cover it completely with "risolin".

"Rizolin" is a self-adhesive flexible material with a foil surface, based on fiberglass impregnated with bitumen-polymer compounds with targeted additives that improve the performance of this coating.

This material is specially designed for flooring on roofing surfaces of any complexity, it reliably waterproofs the roof. "Rizolin" has excellent adhesion to any surface, and plasticity allows it to take the form of slate waves.

The adhesive side is protected by an anti-adhesive backing, which is removed from the material before it is installed on the roof. After removing the protective layer, the sheets are pressed against the surface of the slate and reliably adhere to it.

This material has another important advantage - due to the fact that the outer layer is a foil, "rizolin" prevents overheating of the roof and closes it from direct ultraviolet rays. Thereby old slate as it were “preserved”, and in a house with a roof covered with “rizolin”, it is never hot.

In conclusion, I would like to recall that in 1999 the European Commission adopted a directive banning the use of asbestos and products made from it from 2005 in countries European Union. This decision was made on the basis of studies and the discovery that asbestos can cause serious harm to human health. Therefore, if it's time to repair a slate roof, maybe consider this a reason to completely replace the coating with one of the modern roofing materials, and not to repair cracks and holes?

And in conclusion - an interesting video in which the master shares his secret of preparing glue for repairing a slate roof

Video: homemade glue for slate repair

Occasionally, leaks occur due to the fault of sagging rafters, that is, errors in the calculation and construction of the supporting structure. Much more often - due to poor-quality roofing components and improper installation of the coating. At the same time, each material has its pros and cons, its strengths and weak sides, and, of course, their own recovery methods. We will analyze all the details of the repair.

All about roofing repair

Repair of roofs from different materials

Metal roof

Typically, leaks in this coating occur due to cracking of the sealing washers of the fixing screws. Hence the main rule: fasteners should be purchased only with durable washers made of ethylene-propylene rubber (EPDM). Ideally, before buying, you should consult with the support service of the manufacturer of metal tiles about the reliability of the selected fasteners.

Well, if the trouble has already happened, there's nothing to be done - you have to hire roofers to consistently replace all fasteners(possibly - only on the southern slope). Attempts to identify leaks and implement local measures in this case are useless.

Another common cause of leaks is the loosening of sheets by the wind when fasteners are incorrectly (haphazardly or too rarely) located. This defect is easier to fix - just increase the number of screws and tighten those that have already been installed.

Finally, metal can leak due to through rust in places of damage to the protective paintwork and zinc coating (during installation, falling branches, snow removal, etc.). The method of repair in this case depends on the size of the defect. If it does not exceed a few millimeters, the rust is removed with a metal brush, and then the hole is covered with polyurethane sealant.

If it exceeds, after processing put a patch of fiberglass impregnated epoxy resin(after the resin has dried, this place is painted over with enamel). In some cases (strong dents, holes), it is necessary to cut out a part of the sheet and put a steel patch - it is mounted so that the upper edge goes under the upper part (or ridge cap), and fastened with self-tapping screws, aluminum rivets, or soldering. Similarly, repairs are carried out from roof leaks from a profiled sheet.

From corrugated bituminous sheets (ondulin)

And here the main problem associated with fasteners. The long nails that are driven into the wave are sometimes bent, entering at an oblique angle. As a result, the hole from the fastener increases, and the cap does not fit snugly against the material. If the installers do not immediately eliminate such defects, in heavy rain, when the snow melts, the finish will leak slightly. It's easy to fix - it's much harder to find a crooked nail.

From bitumen sheets, like metal, it can leak due to leaks at the joints. Moreover, the likelihood of such problems is much higher, since the material significantly changes dimensions when heated and cooled. Over time, the joints diverge. In addition, the rough surface contributes to the occurrence of a capillary effect, due to which moisture moves up the slope.

Seal the joints will help additional nails, bituminous sealant. The ondulin of new lines with locking connections is less susceptible to such leaks. Bituminous pastes are inexpensive, but melt in the sun and are therefore difficult to work with in summer. Rubber based formulations are preferred. Local damage on ondulin is eliminated with bitumen-based mastic, the layer of which, if necessary, is reinforced with fiberglass.

From flexible tiles

This material may leak due to improperly or crookedly hammered nails, not removed the film on the adhesive layer, uneven lathing (from low-grade boards without a flooring device from sheet materials). All this interferes with the transformation of the coating into a single waterproof layer, causing the formation of cracks. Moreover, defects usually do not appear immediately after installation. Therefore, repair of a leak in the roof of a glazed balcony, for example, may be needed only after a few years. Moss can help in moisture penetration under the roof.

Alexander Pleshkin, technical specialist of TechnoNIKOL

Among the advantages is its maintainability. If small cracks are found in the shingle itself shingles sealing is required. To do this, use bituminous mastic, which is used to coat the part with cracks on the underside, as well as all joints with adjacent shingles. It is important to take into account that open areas with applied paste must be protected from ultraviolet radiation - sprinkle with basalt chips from flexible tiles. For more severe damage, one or more shingles will need to be replaced. This is done simply: nails are carefully removed from the damaged and from the overlying elements, which additionally fix the damaged one, with the help of a nail puller. Then this element is changed to a new one with sizing bituminous mass (including joints with neighboring parts).

Roof leak repair with self-adhesive sealant

NICOBAND universal self-adhesive sealant tape will help to repair the roof and eliminate small leaks. It is a bitumen-polymer sealing material 1.5 mm thick, covered with a colored aluminum film on top, which protects the tape from UV radiation, gives a frame and allows the sealed elements to be rigidly fastened. From below the tape is covered with an easily removable protective film.

Self-adhesive is suitable for repair work on flexible and natural tiles, metal tiles, slates, rolled materials, as well as on folds. For styling, you will need a tool that can be found in every household - this is a tape measure, a marker, a knife and a rolling roller, or something that replaces it, gloves, a small piece of fabric.

Work order

- Before sticking the tape, the surface must be cleaned and degreased. Surface and material temperature must be at least +5 °С.

- Measure and cut off the required amount of sealant. For more reliable sealing, the tape should cover the hole by 3-5 cm from each edge, depending on the size of the damage.

- Remove the protective film and apply the tape to the surface, then press firmly with your hand, preferably with a rolling roller.

Do not use the tape on wet surfaces. The substrate must be dry and clean, otherwise a secure bond cannot be guaranteed.

Important points of repair and waterproofing of roofs

We will analyze the nuances that will help in carrying out repair work.

Weak points of structures

There are frequent leaks at the junctions with the walls and, as well as in the zone of the valleys (a slope fracture with the formation of an internal corner). The latter are especially difficult to eliminate: usually sealants and sizing the joint on the outside help for a short time, sooner or later you have to dismantle the coating over a fairly large area.

Ways to find a leak

Finding a leak is not always easy. The most common way is to carefully inspect the sheathing and covering from the attic side immediately after the rain and give a knock signal to a partner working outside. It is extremely difficult to find the places of defects in the insulated roof without dismantling the coating, since water flows down through the intermediate layers and is localized on the ceiling much lower than the opening in the roof. When flat roof an electric flaw detector will help.

Condensation problem

Leaks are sometimes confused with the formation of condensate on the lower surface of the roof. To prevent this phenomenon, if necessary, at the construction stage, by providing a ventilation gap and laying a hydro-windproof film over the crate. In a house with a cold attic, increased ventilation of the attic space, as well as additional sealing of the ceiling, will help.

Optimal slope

The greater the angle of inclination of the slopes, the easier the snow comes off them. However, construction costs are rising. In addition, steep slopes are more difficult to move during maintenance and repair. Therefore, you need to choose the golden mean. Let's say in middle lane In Russia, the roofs of houses with a cold attic should preferably be made with a slope of about 30 °, attic - about 45 °.

Optimal shape

Constructions complex shape(multi-forceps, with lucarnes and level differences) are more time-consuming to care for. They have to clean the snow and foliage, more often carry out chemical treatment that prevents the growth of mold and moss. The risk of leakage is much higher.

Repairs are usually carried out independently. This is done when it is necessary to close up small holes or damaged docking areas. If the problem lies in the installation errors, you have to correct them. In this case, they rarely do without a complete or partial dismantling of the system. It is better to entrust it to specialists.

- Material prepared: Vladimir Grigoriev

Although metal roofs are considered very durable, however, in the course of their operation, it will periodically be required Maintenance to replace damaged areas. During this, patches are mounted, cracks are eliminated, and painting is carried out.

Types of iron roofing

For the manufacture of metal roofing, galvanized iron, titanium-zinc, aluminum or copper can be used. To protect roofing iron from corrosion, paint, metal oxides or special polymers are applied to them.

How to prepare a metal roof for repair

The repair of a metal roof is preceded by the preparation of its surface. First of all, dust, rust and other contaminants are removed: a broom and a brush are used for these purposes. Cleaning of rusty places is carried out with metal brushes, with the obligatory cleaning of the resulting dust. The surface is also inspected for cracks and holes: this is usually the result of careless handling of a shovel while removing snow from the roof.

When repairing the roof of a private house with your own hands, it is inconvenient to carry out an inspection alone, it is advisable to enlist the support of at least one assistant. They put one person in the attic, giving him a long stick, the second is on top of the roof, having chalk with him. From the inside, it is much more convenient to detect holes, as an assistant with a stick reports by knocking on a metal sheet. Sunny days are most suitable for such a procedure, which will make it possible to notice even the smallest holes. A partner on the roof immediately marks the defect with chalk. Upon completion of the survey of the entire area of the roof, you can proceed to eliminate the detected flaws.

Ways to repair an old roof from leaking

Local repair of a metal roof from leakage is carried out using patches of two types: across the width of the picture and intermediate. The first method eliminates defects on the plane, in the second - in the ridges or next to them. Sheets with the necessary margin for the size of the wear area are used as a patch (allowances are needed for connection). The damaged area is opened and equipped with a patch, connecting with the old coating. If gentle slopes are being repaired, then the connecting sections can be soldered.

Before installation, the patches are covered with drying oil, and after laying, they are painted with a composition that is resistant to atmospheric influences. In the same way, it is necessary to process the connecting areas in order to avoid their rusting. If the size of the hole does not exceed 200 mm, tarpaulin, burlap or dense fabric is used to make the patch. To close a small hole up to 30 mm, hot bitumen, minium putty or special mastic is used. Around the defect, it is necessary to clean the area of 30-40 mm, followed by double-sided lubrication.

Fabric and burlap patches are impregnated with liquid oil paint, which includes natural drying oil with crushed lead or iron minium. The fabric must be well dried before impregnation. Impregnation time - 10-15 minutes. Next, the patch is squeezed out and placed over the hole: smoothing and fixing is carried out with a stiff brush. Close attention is paid to the edges of the patch. Patches usually take about a week to dry, after which the entire roof surface can be painted. Repairs to gutters, overhangs, gutters and eaves are much more frequent due to the greater vulnerability of these areas during snow and ice removal.

If defects account for most of the entire roof area, then it must be completely replaced. This procedure has the same algorithm of actions as the laying of new material. With dismantled sheets, you can decorate the south side of the slopes, after cleaning, cutting and covering them with paint or drying oil. To decorate a valley, cornice overhang or other critical section of the roof, it is recommended to use only new metal sheets. Before crimping, all folds are treated with putty on minium iron.

Use for repairing roll materials

A cheaper option for repairing a metal roof is to use rolled materials.

In this case, observe next order actions:

- Sheathing repair.

- Restoration of drainage elements, gutters and slopes.

- Fixing swollen and torn fragments on nails.

- Roof cleaning with a metal brush.

- Laying of rolled material in the longitudinal and transverse direction to the standing folds.

- Stuffing on both sides of triangular rails of the same height with folds.

- Laying hot bitumen and gluing roofing material.

The procedure is carried out from the eaves to the ridge: each next row should have an overlap of 8 cm on the previous one. To make it more convenient to lay the transverse strips, standing folds are bent to the roof plane.

Using Polikrov

Overhaul of an iron roof can be carried out using a polymer coating: in this case, it is not necessary to remove the old finish.

As part of "Polikrov" there are polymeric and bulk components:

- Reinforced fiberglass fabric on a roll basis "Polikrov - AR".

- Mastic "Polikrov - M", for fixing the material to the base.

- Bulk coating "Polikrov - L", stacked in several layers.

The roll base is quite easy to lay and glue, and the bulk base contributes to the formation of a monolithic film. "Polikrov" is presented for sale in a rich variety of colors. The most popular color is silver: its reflective characteristics ensure the cleanliness and novelty of the coating for a long time after installation. In the course of operation, the lower roll base of Polikrova is reliably protected by the top layer, which can be renewed if necessary.

To strengths may include the following:

- Possibility of laying on the previous coating.

- After the repair, the parameters of the renovated roof are noticeably increased.

- Laying does not lead to significant weighting of the roof.

- Practically waste-free method (junctions and joints are isolated with residues).

Algorithm for laying the roll-polymer composition "Polikrov":

- Bending the folds.

- Debris cleaning.

- Application of mastic for gluing fiberglass or burlap. The width of the stripes is 15-20 cm.

- Mounting insulating material and Polikrov.

- To finish the ridge, strips "Polikrov-AR-130" or "Polikrov-AR-150" are used.

- The surface of the roof is varnished with Polikrov-L-1.

If the roof can be covered with one strip (20-22 m), a continuous laying from the ridge to the overhang is chosen for covering. Repair of an old roof of a large area starts from the bottom.

Properties:

- Temperature mode of operation - from -60 to +140 degrees.

- The rolls contain 20 m2 of material, with a width of 90 cm and a thickness of 2 mm.

- Mastic is packaged in barrels or cans of 20-200 liters.

- Service life - 25 years.

The most vulnerable areas of a metal roof are the docking points. If there is a violation of the temperature and humidity regime, then these can also include the gaps between the crate bars, along the attic side. This is due to the fact that non-galvanized steel nails, bolts and other fasteners at the junction with galvanized sheets form a destructive electric couple. To prevent such phenomena, it is recommended to use roofing pads.

How to paint a metal roof

Painting is the final stage of iron roof repair. Water, hydrogen sulfide, air, carbon dioxide, sand, dust and smoke are destructive to the paint layer. To minimize their influence as much as possible, painting must be carried out strictly according to the instructions. When applying, it is important to achieve evenness and smoothness of the layers, which will prevent the accumulation of various contaminants.

In case of uneven application, cracks usually occur: water flowing into them will begin to quickly destroy the roofing material. For reliability, paint is recommended to be applied in 2-3 layers. Of particular importance is proper preparation substrate, which must be completely clean and dry. Concerning temperature regime, then most roof paints are designed to work at positive temperatures.

If everything is done correctly, then the repaired metal roof can last a long time. If you find the slightest defect, it is advisable to immediately eliminate it, otherwise the problem will worsen over time.