Facing the basement of the house with artificial material. Basement cladding materials: what is used in modern decoration

Carrying out the exterior decoration of the house, it is necessary to pay attention to all its elements and sections. Particular care requires the study of those details that are in plain sight. These details include the basement - the lower, slightly protruding part of the building, encircling it completely around the perimeter.

For most homeowners, when finishing, a logical question arises - what material to choose so that the basement looks presentable, spectacular, but at the same time, so that it reliably protects the building from dampness, precipitation and destruction associated with these phenomena. In the article we will consider this issue, and find out: what types of finishing materials are suitable for decorating the basement, what are the strengths and weak sides each of them.

Why do you need a plinth

Let's find out why the building needs this part of it.

The plinth is necessary for almost any building, because, in addition to the visible - decorative, it also performs an invisible - protective role. The basement protects the most important, lower part of the structure from precipitation, dampness coming from the ground, and other unpleasant external manifestations. It prevents moisture from seeping into the basement, acts as a kind of waterproofing.

In addition to protecting against moisture, the base also performs the functions of thermal protection. Due to the fact that a reinforced, well-planned and erected plinth retains heat inside the house, building owners can enjoy a favorable indoor climate even in the most severe frost.

But in order to properly finish the base, it is not enough to pay attention to one decorative coating. Before the external, final finishing, a layer of waterproofing, insulation is necessary, then plastering takes place. And only after all these stages comes the time of facing.

You may also be interested in information about what

On the video, how the lining of the basement of the house takes place:

Overview of materials

Find out all the pros and cons various kinds finishing materials suitable for the design of the basement.

Plaster

One of the most popular exterior finishes. The product range, the variety of the palette and the functional advantages of this material are constantly expanding, changing and improving. Best Option for facing the basement will be the choice of facade plaster, designed specifically for exterior decoration.

It looks like facing the basement of the house with plaster

pros

Frost resistance allows the use of facade plaster in areas with any climate - even in the Far North. The basement, covered with plaster, will safely "survive" both dry summer and autumn with rain.

The low price makes this type of cladding one of the most affordable.

A huge palette of shades and textures allows you to choose exactly the plaster that best suits the look of the house. But how plaster is made under the lighthouse can be seen in this

Among other things, plaster is also quite easy to work with. It is possible to carry out facade cladding without the involvement of hired labor.

The plaster allows air to pass through, which favorably affects the internal microclimate of the house. The composition of the material is natural: sand and cement.

With the help of textured plaster, you can mask the defects, pits and irregularities on the plinth, giving it a neat and even look.

Minuses

The disadvantages include not too long service life of the material. In order for the plinth to be reliably protected and the appearance of the building to remain attractive, the plaster will have to be reapplied approximately every four years. Often, in order for the material to last longer, it is coated on top with special facade paints that protect the plaster from moisture and precipitation.

The disadvantage is that this material by itself is in no way able to additionally insulate the building.

Tile

Wonderful facing material for universal use.

pros

The material has a uniquely wide range: you can choose tiles of all colors of the rainbow, any texture, size and other parameters.

With tiles

This finishing material is durable, strong and reliable. The tile remarkably resists aggressive external influences, including weather and mechanical ones. And here is what a brick-like facing tile looks like, and how to install it. can see

Externally, the plinth, trimmed with tiles, looks very neat and elegant, perfectly decorates the house.

Minuses

The disadvantages include the rather high price of this material. The average price for a pack of tiles starts at 800 rubles, so not everyone can afford to buy a decent amount of these packs for finishing the basement: especially if the latter is high.

The tile is capricious in installation. If the owner of the house does not have the skills of laying it, then it is better not to take up work on his own, so as not to spoil the expensive material. You will have to invite the master, which will also cost a certain amount.

In addition to the tile itself, you will also need special glue, grout and other consumables, which will lead to even higher costs.

A natural stone

This is a unique material that can turn even the oldest and most unprepossessing house into a representative and respectable building.

This is a unique material that can turn even the oldest and most unprepossessing house into a representative and respectable building.

Most often, the following types of natural stone are used to finish the basement:

- sandstone:

- granite;

- cobblestone;

- less often - marble.

pros

The material has an almost unlimited service life. If the owner of the house, being in middle age, finished the basement of his dwelling with stone, then for the rest of his life he will not have to worry about this problem now.

The stone has a completely natural origin, which increases the environmental friendliness of the home, and has a beneficial effect on health. The design of the house will become unique, because nature has not yet created two identical stones.

The material is also surprisingly durable. Natural stone is able to withstand any external influence: chemical, mechanical, atmospheric. And if a stone suddenly falls off the wall during operation, it will not be difficult to glue a new one in this place. But how can you use a facing stone, and how to do all the work

On the video, facing the basement of the house with natural stone:

The range of natural stone is very rich: a variety of textures and colors makes it possible to match the material to any shade and design of the building. Finishing the basement with natural stone makes the building "expensive", representative and respectable. A similar impression will arise in everyone who looks at a house finished in this way. Therefore, if financial problems do not bother, natural stone is perhaps the best choice.

Minuses

The downside is the high price. Due to its strength, naturalness and high aesthetic properties, this material is unlikely to ever be cheap.

Natural stone is not easy to install. It is best to entrust this responsible matter to a specialist with extensive experience in such work.

Stone is a heavy material, so the additional load on the foundation will be hefty. It is necessary to make accurate calculations in advance in order to find out whether the foundation of the building will cope with such a “load”.

Read also about finishing the plinth of a pile-screw foundation.

Fake diamond

Outwardly, this material can not be distinguished from its natural counterpart. The benefits are also very similar. There are some differences, and we will list them.

pros

Artificial stone is cheaper, which means that this type of material is available more of people. At the same time, technical characteristics and external decorativeness are not much inferior to the "original".

Synthetic stone weighs less than natural stone, so it will not create a large load on the foundation.

disadvantages

Of the minuses, one can name, nevertheless, the insufficient lightness of an artificial stone. Although it is certainly lighter than natural.

To carry out the laying of the material, it is necessary to properly level and prepare the surface of the base. This will also require costs: time, power and financial.

Artificial stone must be treated after laying with protective compounds that will ensure its moisture resistance. It also adds money and time costs.

Siding

A modern finishing material that came to us from the Scandinavian countries.

pros

Siding, due to its multi-layer construction, reliably protects the facade from atmospheric influences. In addition, the finish looks very neat.

Siding can be made from different materials, which gives a certain scope for choosing the most suitable type. Siding can imitate different textures: including brick, wood, stone.

This finishing material is very easy to install - it is not necessary to invite specialists. The panels are assembled according to an elementary scheme, which is easy to understand even for a beginner in construction.

In addition, siding is quite durable.

There are no serious cons found in this material.. Flaws and defects in the operation of siding can only appear if the choice fell on a low-quality material initially. And here is what a ventilated facade siding looks like, you can see

PVC panels

Also one of the modern, technological materials. The panels are widely used in interior and exterior decoration of buildings.

Facing the basement of the house with PVC panels

pros

Panels are ways to imitate different materials, which allows you to decorate the facade at a lower cost.

Can be used both for plinth and for finishing the whole house: this material is characterized by rare versatility.

The panels withstand temperature extremes well, so they can be used in areas with almost any climate.

The ease of installation makes it possible to cope with the finishing of the basement on your own, without the need to hire specialists.

The downside is the unnaturalness of the material, and its somewhat "cheap" form.

Facing the basement of the house with porcelain stoneware

Among other things, this material is a wonderful heat insulator. Thanks to this quality, the owners of the house will be reliably protected from the cold.

And the fundamental disadvantages of this material were not found. The main thing is that it fits the external design of the building.

We examined the features of the choice of material for finishing the basement. As you can see, in our time we can choose from many worthy, noteworthy options. A wealth of decor, colors and textures will help you choose the material for absolutely any external design of the building, making the house look unified and harmonious.

What material is best for facing the basement of a house? This question worries many who are faced with the need to finish this design. The plinth encircles the entire house and is an important element that protects the building (especially its lower part) from the harmful effects of the environment. In addition, it plays an important decorative role.

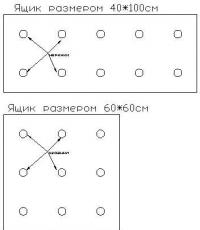

There are several types of basement at home, each has its own characteristics. Various forms are shown in the photo:

- sinking. This variety is a structure that is located with an offset inward in relation to the main facade. The recess is most often at least 50 mm. Such a device allows you to perform work at low cost, as well as make the drain less noticeable.

- In one plane. This option requires complex sealing, so the drain system must be fixed at the stage of general construction. This will avoid further problems.

- Speaker. To sheathe such a basement at home with your own hands, it is necessary (as in the previous version) to think over the drain system in a qualitative way. If it is not installed correctly, water accumulates in the area where the foundation and wall are separated. To avoid such troubles, moisture removal is planned taking into account the finishing of the facade.

Drain device for a protruding plinth when finishing the facade with siding

Drain device for a protruding plinth when finishing the facade with siding On a note! When choosing a material for cladding, one should take into account the design features.

The need for finishing

If the finishing of the foundation of the house has not been completed earlier or the old cladding has become unusable, then the outer cladding must be made. Its main functions:

- Protection of the foundation of the house from environmental influences (precipitation, sunlight, wind). This allows you to significantly increase the durability of the entire structure.

- Additional insulation. If required, a layer of thermal insulation is created, which can be associated with the insulation of the blind area. This procedure not only improves the energy efficiency of the building, but also saves it from many problems. The top facing layer will hide the insulation and serve as an additional barrier against the penetration of cold.

- Decorative. The area is finished properly and suitable material, can emphasize the overall direction of the design.

Based on these parameters, the building products necessary for the work are selected.

How to sheathe the foundation of the house outside?

The material for the base is purchased taking into account the following factors:

Also pay attention to the manufacturer of the product and the place of purchase. It is better to give preference to trusted brands and specialized outlets.

Types of finishing materials for the plinth and features of their installation

When choosing a material, you need to consider the method of its installation. There are options that are mounted directly on the walls, but there are also those that require the construction of a frame.

Materials for finishing the foundation, installed on the crate, are relatively new products. This list includes types that differ in technical characteristics.

Panels

This includes panels made of different materials, it is customary to include siding and corrugated board in this group. When choosing, it is better to give preference to options that are made specifically to finish the base. They have more stable characteristics and may include an additional layer of thermal insulation.

plinth trim decorative panels

plinth trim decorative panels

Among the advantages of the products are:

- Availability. Indeed, it is this variety that makes it possible to perform work inexpensively. This option allows you to get a balance of price and quality. But it is necessary to refuse products with too low cost. Most likely, they are made of low-quality plastic, which will quickly become unusable.

- Ease of installation. Paneling occurs with the help of a tool that every home master has, so you do not need to involve specialists for work.

- Possibility of additional thermal insulation. Installation on the frame solves two problems at once - ventilation and insulation. This will save the coating from freezing, reduce heat loss and the likelihood of mold and mildew.

- Decorative. Panels, especially basement panels, have a well-defined imitation natural materials. That is, the lined area fits perfectly into the design idea and the environment.

Attention! The choice of inappropriate products can greatly spoil the result. For example, corrugated board for such a process must have increased rigidity, that is, have a durable top coating.

Porcelain stoneware and types of tiles

Porcelain stoneware and clinker tiles in the form of large parts are mainly used for plinth cladding. The second option can also be laid by the wet method, then fragments of the material are used. Porcelain stoneware, due to its large weight, is installed only on the crate, while it must have increased reliability.

Advantages of porcelain stoneware and tiles:

- Small load on the building. This effect is achieved due to the frame, which takes on the main pressure.

- Fast installation. It is possible to revet the foundation of a house in a short period of time, but it is extremely problematic to do this without a certain experience. Porcelain stoneware needs to install special fasteners, which is not always possible without understanding the process. The tile is fixed much easier, for this there are special metal ears.

- Durability. The service life of such materials for the foundation is calculated in decades.

- Moisture resistance. Parts do not absorb water well, so they are not subject to deformation.

Such materials for the foundation have a significant disadvantage - high cost. You do not need to purchase cheap tiles, as this often indicates poor quality. For work, a variety for the street with the "Snowflake" icon is used.

An alternative to tiles can be artificial stone. Elements are installed on the crate through special holes or directly.

On a note! At the moment, thermal panels are becoming increasingly popular, which combine the advantages of panels and tiles. They are a base with insulation, on which clinker tiles are applied.

How to sheathe the foundation using crates

All options for finishing the basement, which involve installation on the crate, have common technology sheathing structure:

- Work begins with the preparation of the foundation. It is cleaned of dust and dirt, all cracks are carefully covered with putty. If there is serious damage, then before finishing the basement of the house, it is advisable to strengthen the foundation.

- Due to the fact that this part of the building is exposed to more moisture, it is treated with antiseptics. It is better to impregnate in several layers.

- After preparing the surface, the frame is erected. For this purpose it can be used wooden beam or metal profile. It is important to consider that wood needs to be treated against rot, and metal parts can not be cut with a grinder, this leads to corrosion.

- Racks are installed perpendicular to the direction of laying the material. If the products have the same sides, then the vertical method is considered preferable.

- A heater is placed in the resulting cells. It is fixed on special anchors.

- Vertical connections are mounted between the racks of the frame and a place is left for installing a low tide.

- The material for finishing the plinth is laid in several ways: overlapping, by means of a tenon-groove connection, on special brackets or clamps. Fixation is made on self-tapping screws. If the products are subject to thermal expansion, then the fasteners are loose.

- The tide is installed.

For the foundation trimmed with panel elements, additional moldings are used. They are installed at the corners for a better decorative look.

Frameless way

It is possible to clad the basement of a house without the help of a frame; for this purpose, different variants products.

Brick

Features of the material application:

- Great for pile or block foundations. But for the installation of brickwork, it is necessary to create a reliable support.

- The resulting coating has good resistance to external influences.

- Products with low moisture absorption are used for work. If this parameter is not taken into account, then the surface is deformed.

- This type of plinth finish does not differ in affordable cost, and certain experience is required for work.

Masonry creation algorithm:

- The coating is being prepared.

- If there is no reliable support, then a foundation block will do. He burrows into a prepared pit. This is especially true for pile foundations.

- Waterproofing is laid on top of the base. In this capacity, roofing material can act.

- The first row is mounted after a thorough level check. In this case, the spoon version of the masonry is more suitable.

- To ensure reliability, a bunch is arranged. For this, anchors are installed in the foundation. If this method is not possible, then a wire with fixation on piles is used.

- The tide is installed.

The difficulty lies in the need for reliable laying of bricks.

Artificial and natural stone

Facing the foundation with artificial or natural stone is not the best simple task especially for the second option. Both varieties have excellent technical specifications in terms of durability and reliability, but natural products need more careful maintenance and have a high cost.

Laying natural stone is carried out as follows:

- Regardless of the type of finish, the surface must be carefully prepared.

- Due to the heavy load, the foundation should be covered with a reinforcing mesh and covered with a layer of plaster.

- Laying of parts occurs after drawing up the markup. If the fragments are irregular in shape, then they are first laid out on a flat area.

- Fixation is carried out on a special glue, which is applied to the surface, the wrong side of the parts is slightly moistened.

- A small gap must be left between the fragments, it compensates for thermal expansion.

- If required, the joints are grouted and the tide is installed.

According to a similar principle, the basement of the house is finished with artificial stone and tiles.

Plaster

Plastering is the most economical option that allows you to perform work without the involvement of specialists and sophisticated equipment. For this process, a special type of mixture for external use is used.

On a note! Finishing the foundation with your own hands using plaster is carried out in two ways: without additional thermal insulation and with insulation.

General technology of work:

- The surface is being prepared.

- A layer of glue is applied on which the heat-insulating material is fixed.

- After the composition dries, the insulation is additionally strengthened with special dowels.

- Next, a small layer of mortar or glue is applied to the surface, after which a thin reinforcing mesh is stretched. It should be completely covered with the mixture.

- The surface is left to dry.

- The final layer is plaster. A spatula is used for its application, and a rule for leveling.

- At the end of the work, the surface is covered with a protective layer of paint.

This method allows you to bind the insulation to the thermal insulation of the blind area.

Plinth decoration

Decorative finishing of the foundation is considered an integral part of the process. The following options apply:

- Coloring. It is carried out even after the passage of time. You can choose a shade that is most suitable for the cladding of the house and favorably highlights the plinth.

- The use of decorative or textured plaster. Such material is tinted and may include a fraction of natural stones or sand. It gives an unusual effect when applied correctly.

Decorative plaster in the design of the basement

Decorative plaster in the design of the basement - Creation of a relief surface. For this, simple facade plaster is used, on which an imitation of stone or brick laying is formed. Additionally, staining is carried out in different tones.

- The simplest is the use of materials with the desired imitation.

Working with a plinth is a rather complex undertaking, the basis of which is right choice products.

Wall cladding of the basement decorates the facade of the house and protects the lower part of the wall from getting wet. Basement masonry can be plastered, overlaid with stone or tile. The question arises, what material is better for facing the basement of a house, and what should be considered when choosing an exterior wall finish?

Facing the house: what material to prefer?

Modern building technology offer a variety of materials for exterior wall decoration. They are divided into coating (various paints, plasters) and masonry (, stones, bricks). The choice of material depends on the operating conditions and requirements that apply to the outer cladding. What should be the basement finish?

- Moisture resistant- the material must protect the walls from moisture. The lower part of the walls gets wet more than the facade. Drops of moisture are sprayed onto the plinth from the surface of the blind area.

- decorative- the material must match general style buildings, combined with wall cladding, look aesthetically pleasing.

- durable- lining of the basement of the house must withstand at least a few seasons and do not require annual renewal.

- The cost of facing materials and their installation should not be fabulous.

Options for facing the basement of the house

The choice of material for lining the plinth is carried out between plaster coating or decorative masonry. Cheaper and easier to plaster the walls of the basement with a special mixture.

Important! To ensure moisture resistance, substances such as Penetron are added to the plaster composition, which form water-resistant crystals in the pores and guarantee absolute water resistance.

Plastering the basement is characterized by low durability. More reliable - facing (tiles, natural or artificial stone). What are the advantages and disadvantages various materials outer cladding?

Facing the basement of the house with natural stone

Natural stone for plinth cladding- This is the most expensive and durable cladding option. As facing elements, sandstone, limestone, slate are more often used, less often - marble or granite. At the same time, sandstone and limestone must be treated with a water repellent after masonry (their resistance to water penetration is insufficient, although the decorative effect is very high).

The dimensions of the masonry stone can be large and small, the texture is smooth or embossed, the surface is raw or polished.

For installation, a special adhesive solution is used. If the adhesive is not designed for heavy stone slabs, the lining may peel off.

Important! Stone cladding needs a solid foundation.

The disadvantage of natural stone cladding is a small color range and significant weight. In addition, the price for work when facing the basement of a house with natural stone will be higher than any other option.

Facing the basement of the house with artificial stone

It differs from the natural price and variety in the choice of colors. It is more accessible, while being very decorative and prestigious.

The basis of artificial stone is concrete. Dye, water and frost-resistant additives are added to its composition, after which it is poured into molds. Hardened artificial stone imitates granite, "torn" stone, rock and sandy rocks.

Artificial production provides a color variety of the stone. Molding determines the presence of a flat side and the correct perimeter, which ensures ease of installation of artificial slabs.

Here is a video about laying artificial stone on various surfaces:

Tiles for the plinth of the house

There are several materials for the manufacture of outdoor plates:

- concrete mix- stone tiles are made from it.

- Ceramic mixture- for casting clinker tiles.

- concrete tiles - cast from dense low-porous concrete, the moisture resistance of which is 97%.

Clinker tiles- a material that looks like clinker bricks, but differs from it in thickness. Clinker does not absorb moisture, does not require any additional protection, impregnation from getting wet.

For gluing tiles, a special frost-resistant adhesive mixture is used.

Polymer sand tiles- composite moisture-resistant material that externally imitates any type of masonry ( brick wall, smooth or broken stone). An important advantage of the polymer is that it is light in weight and can be mounted on the plinth of frame structures.

Polymer sand slabs are mounted on the wall over the crate. Thanks to the fastening to the frame, it can place a layer of insulation under it.

Here you will see a video about the installation of plinth panels:

Flexible polymer tiles

It is made from synthetic resins. The flexibility of the material allows it to be used for lining uneven plinths (arc-shaped, overhanging, inclined elements), as well as bending tiles at the corners of the building.

Synthetic material provides high manufacturability and decorative coating. Polymer tiles can be glued to solid concrete, brick or a layer of insulation. It can have a different color and surface (smooth, embossed).

Plaster

For external plastering of walls, various compositions are used:

- concrete plaster- requires the addition of moisture-resistant components, after hardening it can be painted.

- Synthetic plasters(silicone, acrylic) - available in any color, are waterproof.

- Mosaic plaster- includes stone "grains" up to 3 mm in size, which imitate a mosaic.

Comparison of prices and quality of materials

The table below will help compare the characteristics of cladding materials and their quality, as well as the cost of future cladding.

Before deciding what the base should consist of, you need to know what it serves for.

The plinth is not just a protruding step, not a design element, it is a continuation of the foundation, therefore, first of all, it must be solid and protect the house from moisture, temperature extremes and possible groundwater. It is very important that not only cold and moisture do not penetrate into the room, but also steam is removed from the inside of the house.

If you do, then first. A common problem in the fight against humidity in the house is the neglect of the preparatory work. It is very important to carry out all work on the installation and finishing of the basement in dry, warm weather. So, drainage is our everything!

- We dig a trench along the perimeter of the building, 50 cm wide, 20 cm deep.

- We fill the trench with gravel, which provides drainage. If desired, you can strengthen the reinforcing mesh.

- We clean the surface of the wall of the future basement - 50-70 cm from the ground from dirt, treat it with water-repellent primers, the so-called water repellents, and if necessary, level the bumps.

- If you are a perfectionist, you can additionally clad the wall with carpet synthetic material with an air gap. This layer is formed near the wall and ensures the evaporation of part of the moisture.

- We do insulation. It can be insulated with polystyrene foam, polyurethane foam, extruded polystyrene foam and mineral wool. The latter option is not very good, since mineral wool loses its insulating properties over time.

- Now we proceed directly to the lining of the basement.

Of course, before even starting preparatory work, you must select the material of the cladding.

When choosing a material, a number of factors must be taken into account: price, durability, degree of protection, lightness, appearance. The base can be non-protruding and protruding. If you chose the second option, you must use ebbs. We'll consider different types plinth cladding with pros and cons.

Finishing the plinth with plaster

The easiest option is plastering followed by painting.

pros- economical and relatively easy to implement option. This work can be done independently, without resorting to the services of specialists. If you choose a good facade paint, you can give a very well-groomed look to the house.

Minuses- unstable to chips and cracks, short-lived.

Stages of work:

- clean the work surface from dirt and bumps.

- we process the wall of the future basement with a primer. It is necessary to carefully lubricate all the cracks, chips. It is important not to rush to the next step and let the primer dry completely. This may take more than two days.

- put plaster on the wall with a spatula. You can make a stone effect out of plaster, but still, for this you need to have modeling skills, but you can look quite impressive, especially after coating with paint. If you do not have such skills and work on your own, it is enough to smooth it with a spatula, let the composition dry, also for about two days, then sand and paint. Most commonly used acrylic paint. It is waterproof, and at the same time vapor-permeable and frost-resistant. Polyurethane, alkyd and silicone paints are also used. Enamel paints are not recommended because it is environmentally unsafe and does not allow air to pass through.

If you decide to make a plinth by plastering on a grid, you need to add after applying a layer of plaster adhesive composition and, about a third, press a polymer mesh into it, which is smoothed from above with a metal trowel.

After another two days, cover the resulting base with an acrylic primer.

But that's not all. If you are not a sculptor, but want to make the effect of natural stone with your own hands, rejoice, modern technologies have solved this problem as well.

So, on the pre-treated surface, we first apply a cement solution, then a decorative layer of plaster, level it with a spatula ... and make an impression with a special mold. The downside, of course, is that it must be purchased. But then everyone will take your plastered basement for a stone one.

Prices for popular types of plaster

Plaster

Finishing the plinth with concrete

This method of finishing the basement is more reliable than ordinary plaster. It is also suitable for subsequent finishing of bricks, PVC panels and tiles. But you can do it even easier. After concreting, paint the plinth with concrete paint.

Stages of work:

- we fix a metal mesh on the base. It is better to choose a grid with a cell size of no more than 1 cm with a three-dimensional structure. This will allow to achieve a larger area of contact between the grid and the solution, which will improve the reliability of the base. We fasten the mesh with fast mounting dowels or nail dowels.

- we make formwork. When preparing the formwork, we put guide boards and fix them with pegs that are hammered into the ground. Next, we fix the shields in a vertical position, first on one side, then on the other. Every half a meter we fasten the shields with spacers and additional clamps, they will not allow the formwork to open when pouring concrete. Outside, you can fix with spacers or pegs.

- we pour the concrete, wait for it to dry, remove the formwork, paint it and voila - your basement is ready!

stone finish

Stone decoration, of course, looks better, although the taste and color ... But still, stone, natural or artificial, will last much longer, better protect against external influences.

Consider options for finishing the basement with stone.

A natural stone

Natural stone, which is used in the decoration of the plinth, can be sandstone, limestone, granite and even marble.

Marble, of course, looks rich. But this very expensive material has a big minus - it absorbs moisture, dirt. It can be washed, but it is also very difficult. Therefore, marble is rarely used. But that's not all. There are options and more expensive than marble, generally with exorbitant prices. This is, for example, labradorite. It combines the unique color and strength of granite, creates multi-colored reflections under different lighting conditions. Your home will literally shine with colors at different times of the day. But you will have to pay a lot for this.

Pros: A house with a stone plinth looks much more solid and impressive. Longer service life, no need to repaint or finish anything, chip resistant.

Minuses: Natural facing stone will cost you more than plaster with painting and finishing with other materials. Another disadvantage is stone - the material is quite weighty not only externally, but also in its mass, and this gives an additional load on the foundation. In such cases, a reinforced connection of the drainage cushion with the foundation is mandatory. Often, stone requires complex installation and, therefore, entails an increase in the installation price. For example, granite blocks must be reinforced in addition to the mortar and special stops must be used.

Stages of work:

Since natural stone is very heavy, we need to strengthen the surface of the plinth:

- with the help of special fasteners we mount the grid to the wall.

- then we impose a solution of concrete or plaster for finishing work on the grid.

Applying the solution to the mesh

- after the surface has completely dried, we treat the base with a primer using a roller or brush.

- the next stage, again after drying, we apply a special glue of increased strength.

- we fix the stone on the glue in much the same way as the tile, it is possible without the use of cruciform beacons. Natural stone does not require the same distance between the seams, as the size of the stones can also differ from each other. Be sure to wipe up any escaping solution.

- after complete drying, apply grout.

Fake diamond

The material is made on the basis of cement-containing mixtures with the addition of expanded clay crushed stone. There is simply no limit to the imagination here. Such material is made in various sizes, profiles, color shades. That is, you can choose the design, color, size for the style of the whole house, ideally choose the basement cornice. Artificial stone can be with a rough or smooth surface. All of the above can be attributed to the advantages of this coverage. Minus - the high price of the material.

Stages of work:

It would seem, what is the difference? Both are stone. But in this case, the weight of the artificial stone is still lighter and we can go in two ways of installation. The first way, as in the case of natural stone cladding, we reinforce the basement surfaces, the second way does not provide for such a solution:

- alignment

- padding

- gluing the stone to the surface.

- grouting.

Finishing with clinker bricks

This material is made from fireclay - refractory clay, this is its plus and advantage over ceramic bricks and facade plaster. Water repellent and frost resistant. Manufacturers give a guarantee for a brick of 50 years. Cons - rather large weight and high price.

Stages of work:

The brick finishing technology is almost similar to the technology using artificial stone. Only cruciform beacons are used in without fail.

Be sure to take into account the hardening and drying time of the adhesive mixtures used.

Important: start work from the corner and lay out brick and stone from right to left.

Clinker tiles

In terms of size and appearance, you will not distinguish tiles from bricks. But the biggest difference between tiles is their thinness and lightness. Tile thickness from 8 to 21 mm. It is also convenient that there are corner elements, which allows you to perfectly close the corners of the plinth. pros finishing with clinker tiles - it is frost-resistant, moisture does not penetrate into it, it is very durable and has a long service life.

When installing clinker tiles, as well as other similar finishing materials for external use, it is important to use frost-resistant adhesive solutions and joint mixtures.

Stages of work:

- prime the surface

- apply special frost-resistant glue. Here it is important to apply a layer of glue no more than 1 sq.m., because after 30 minutes the glue hardens, and you simply do not have time to glue the tiles. In this case, we use cross-shaped beacons to create equal distances between the tiles.

- after gluing the entire tile, fill the seams.

Plinth finished with clinker tiles

Prices for various types of clinker tiles

Clinker tiles

Basement siding or PVC panels

Finishing the PVC panel can be attributed to one of the cheapest options, which is its plus. Also, this material is convenient in that it is easy to install, convenient to wash, it is very light, frost and moisture resistant, and it does not burn well. Here, as in the case of clinker tiles, there are also corner elements, which is very convenient. Manufacturers offer many design solutions. You can install siding under brick, stone, mosaic tiles, wood. By the way, what is remarkable. With this material, you can finish not only the basement, but the whole house.

The method of fastening the panels to the plinth is completely different from the previous ones. There are no adhesive solutions here, a metal or wooden crate is used, which allows the house to "breathe".

Don't forget to purchase connecting elements with plugs and guides.

The disadvantage of such material is debatable. Someone believes that it contains substances harmful to human health, but manufacturers assure that this is not so.

Stages of work:

- The first step in this case will be the manufacture of the crate. Lathing materials usually use special profiles with wooden slats. Of course, all materials must have the main characteristic for the base - water-repellent. That's why everything wooden surfaces treated with a moisture barrier. In the manufacture of crates, we use a water level and a plumb line. The material is large in area, so it is necessary to avoid distortions of the structure.

- waterproofing film can be used as waterproofing

- we mount the insulation using special clips or adhesive tape.

- using self-tapping screws, we attach plugs and joints around the perimeter of the entire structure, to which the panels will be attached.

Scheme of installation of siding panels

Siding prices

Basement thermal panels

Manufacturers do not stand still, they come up with more economical and ergonomic solutions. Plinth panels are clinker tiles or artificial stone tiles, reinforced on a thermally insulating polyurethane foam base in exact observance of the rows of "brick laying". plus is a more convenient fastening, since the panel consists of about 12-14 "bricks". Minus - artificial materials, as with PVC panels.

Socle thermal panels made of polystyrene are very short-lived. This is a temporary fix. The best material in terms of durability for thermal panels is polyurethane foam. Therefore, when choosing this material, be sure to ask about its basis.

The stages of installation of thermal panels are identical to the plinth siding made of PVC panels.

Prices for various types of basement thermal panels

Basement thermal panels

Mosaic plaster

This plaster in its properties is completely different from the usual one due to the binding element - resin. The resin gives a very important property to the plinth - it becomes waterproof and vapor-permeable. And this is just what you need! And also the advantages of this material include resistance to low temperatures and ease of application. The plaster contains small grains from 0.8 to 3 mm in diameter and looks like a multi-colored mosaic.

The downside is that it cannot be applied to calcareous, heat-saving surfaces, as well as to surfaces made of artificial stone. It may also require adjustments during its operation.

Stages of work:

- clean and prime the basement surface

- apply a layer of ordinary plaster. You can do without it, but it will serve as an additional leveling stage.

- using a stainless steel grater, we apply mosaic plaster. It can be applied to lime-sand, gypsum, cement plastered surfaces and concrete.

Porcelain tiles

This also includes quartz agglomerate - a slab of quartz or granite chips, again based on resin. The advantage of these materials is their high strength and resistance to external influences. It can even be called eternal, it would be perfect option. If not for the minus - the high cost.

Stages of work:

- we install a metal stainless frame to the wall using self-tapping screws, starting from the bottom of the structure, then the guides and side strips. The distance between the wall and the frame is 2-5 mm. This is necessary for ventilation.

- on top of the frame between the guides we fix the waterproofing film.

- we fix the tile on the frame, having previously applied a thin layer of concrete mortar. The solution should be thick enough. We install the tile on the frame using fasteners on the tile.

Important: Be careful when working with porcelain tiles. Despite its strength, during installation, the edges of the tile may break off, which will lead to a loss of tightness between the seams.

Prices for various types of porcelain stoneware

Porcelain stoneware

flat slate

Flat slate is made from a mixture of asbestos, water and Portland cement. Slate is pressed and unpressed. In our case, it is better to use pressed, it is more durable. This material has a lot of advantages. Due to the asbestos in the composition, it is very durable and fireproof, does not corrode, is flexible enough, is not subject to temperature changes, is durable, and does not heat up in the sun. It has good sound insulation and thermal insulation, resistant to aggressive environments. And most importantly, it has a low price. Cons - when sawing slate, harmful asbestos dust is formed, it is inconvenient to install it alone, helpers are needed.

Stages of work:

- we prepare the surface of the basement, primer, insulate.

- preparing a wooden crate.

- we fasten the flat slate to the wooden crate, as well as to the drywall using self-tapping screws. We start from the corner of the house.

- the slate attachment points at the corners must be closed with galvanized iron corners using screws.

- paint the slate, best of all with acrylic paint.

Important: before installation, it is necessary to treat the slate sheets with an antiseptic composition. If the thickness of the slate is more than 1 cm, the sheet should only be cut with an electric saw in order to avoid a large amount of asbestos dust.

So, when everything is ready, we proceed to the installation of low tides in order to prevent damage to our plinth by flowing water. Otherwise, all efforts will go down the drain.

Installation of ebbs

They can be metal, aluminum, plastic. A more beautiful, but expensive ebb can be installed from clinker figured bricks or clinker beveled tiles, but there is quite hard way installation, so you can not do without a professional.

Stages of work:

After facing the basement and before facing the walls of the house, it is necessary to strengthen the ebb.

- for better adhesion of the ebb to the surface of the base, we make slopes at an angle of 15 degrees, align the top line to horizontal, if necessary. The cement mortar must be thick.

- we wait a few days, the cement should dry thoroughly.

- we fix the ebbs directly to the wall on the dowel-nails.

- if the facade of the wall will be sheathed along the guides, then the ebbs must be attached to these guides with self-tapping screws.

Important: ebbs must protrude at least 50 mm above the plinth. Planks are fastened to each other with an overlap, with obligatory lubrication with frost-resistant sealant.

If you are using wide metal sills, you must additionally use brackets for fixing to the wall.

The process of finishing the base is a rather laborious process, so it is important from a huge selection building materials to finish it still use quality materials so as not to regret anything later, since the basement is a very important part of the house for maintaining the warmth and strength of the building. And do not forget about the exterior of the building, everything should be harmonious.

Video - Beautiful do-it-yourself plinth

According to the architectural canons, the plinth is a part of the building lying on the foundation, and is considered as a transitional wall between the foundation and the outer walls of the house. The complex of works on the exterior finishing of the entire building includes measures for finishing the basement, while the finishing materials for the basement of the house are somewhat different from the materials chosen for finishing the walls of the house. This is due to the proximity of the basement to the ground, where it is more susceptible to moisture and cold air than the walls of the residential building themselves. Thanks to the development modern technologies finishing the exterior surfaces of residential buildings and creating new finishing materials, the builders of private houses have received ample opportunities for arranging original and practical plinths within affordable prices.

After finishing the basement, it even visually differs from the building. Source domzzz.ru

Purpose and functions of the base

Builders and architects have different interpretations of the purpose of the basement. Builders consider the plinth as part of the foundation, while architects consider it to be the lower part of the wall.

It is interesting! From the point of view of ancient Italian architects, the plinth is independent constructive element- at the foot of a building, column or monument, lying on the foundation (Italian word "zoccolo" literally translates as a shoe with a wooden sole).

In accordance with building codes, the foundation walls must be raised above the ground to a height of 15 to 250 cm. This visible part of the base, called the foundation wall, is called the plinth. The plinth is an intermediate structure that combines bearing walls buildings with foundations. On fig. below is a concrete foundation, in which the plinth is brick.

The construction of a brick base on the foundation Source vi.decorexpro.com

The main functions of the basement wall of the building are:

perception of the load from the upper part of the residential building (bearing function);

ensuring the stability of the building, creating a solid pedestal, the perception of linear deformations during the settlement of the house (support function);

protection of walls from the effects of atmospheric sedimentary moisture (waterproofing function);

providing thermal protection for basements (heat-insulating function);

fencing the space between the piles and the grillage in the case of a pile foundation (enclosing function);

creation of an appropriate architectural appearance of the erected building (architectural and decorative function).

Video description

More about the advantages of the basement on the video:

Differences between basement and basement

The basement floor, also called the ground floor, should not be confused with the basement and presented as a kind of dark, damp room.

It is important! The basement floor is located inside the perimeter of the foundation walls and can be equipped in buildings with any type of foundation. The basement can only be equipped inside the strip foundation. In some variants of foundations (such as piles), the plinth is simply absent. In the case of a pile foundation, the pile heads are raised above the ground to a height of at least 20 cm, and a grillage is laid on them, which serves as a support for the walls of the house.

On fig. Below is a house on a pile foundation, where the piles protrude at a considerable distance from the ground. To close the resulting free gap, a false plinth is formed by laying piers of facing bricks or sheathing piles with decorative panels such as siding. Finishing the foundation will be inexpensively provided using materials used for outer skin facade, taking into account the location of the false base.

For such a house you need a false base Source tema.ru

Using the example of false plinths, the main differences between the basement and the basement become clear:

The walls of the basement of the house are always load-bearing, the load from the upper floors of the building is partially distributed on them. The walls of the basement are not always load-bearing, but can only perform enclosing and architectural and decorative functions without the perception of weight loads from the building.

The ground floor can be buried to a slight depth or even be above ground. Basement - a room buried in the ground. Basement can be categorized ground floors, while the basement is not always buried in the ground and cannot be considered a basement in such cases.

Ground options for the ground floor are preferable in regions with deep freezing of the soil and during construction in areas with closely spaced groundwater. The arrangement of basements in such cases is very difficult and is associated with significant financial costs.

Despite such a significant difference in purpose and design, the ground floor and the basement allow for identical practical applications in relation to each other - on their areas you can equip a workshop, a garage, plan living room and even build a full-fledged sauna.

Types of base structures

Practiced options for finishing the basement of the house take into account its location relative to the plane of the outer wall (see the figure below):

Types of location of the base relative to the wall Source domsireni.ru

a - protruding type;

b - in one plane (flush);

in - sinking.

The figure shows the following positions:

pos. 1 - outer wall;

pos. 2 - waterproofing;

pos. 3 - foundation.

The protruding type of foot (pos. a) gives the building the appearance of a powerful building of increased stability. From an architectural and aesthetic point of view, the protruding type is more advantageous than the foundation walls, made flush or recessed.

Appearance of the protruding base Source remont.kz

However, they necessarily require the construction of a protective eaves with drain functions to prevent water from running off the walls onto the basement. The construction of a foundation wall of a protruding type is advisable for houses with thin walls or when building a warm underground for its thermal protection, in order to compensate for the small thickness of the outer wall with its width.

A sinking-type basement (pos. c), when the outer wall (pos. 1) hangs over the foundation (pos. 3), is considered more effective and reliable in terms of protecting the waterproofing layer (pos. 2) from mechanical stress and atmospheric moisture. It is more economical in terms of material consumption, since the thickness is less, and the construction of a drain cornice is not required. But as for its aesthetic qualities, the opinions of architects differ diametrically. Some are convinced of the aesthetic loss due to the impression that the house has a reduced stability compared to the actual one. Other designers consider the outline of the sunken plinth to be more compact and modern.

It looks like a wall with a sinking plinth Source domsireni.ru

Sometimes the plinth is built flush with the plane of the wall. It is believed that in such cases the waterproofing line is broken, and the location of the waterproofing layer itself looks random.

When constructing a flush base, it differs only in color. Source 2gis.ru

The purpose of the basement finish, requirements for finishing materials

The basement experiences a greater volume of loads than the underground part of the base of the building. Along with the weight load from the entire structure, it has to counteract the buoyancy forces from the soil during soil heaving, that is, the mechanical loads on the base turn out to be multidirectional.

It is clear that for finishing the surface of the basement wall, it is necessary to use materials with increased quality indicators compared to traditional cladding. In addition to mechanical loads, they must withstand the effects of the environment well:

temperature fluctuations;

negative impact of sedimentary moisture - rain, snow, melt water, condensing fog;

exposure to solar ultraviolet;

wind loads.

As a result, finishing the basement of the house is carried out for the following purposes:

minimization negative impact on the foundation and the lower layers of the outer walls of the weather conditions of the environment;

preventing the penetration of dirt and chemical compounds into the materials of the walls of a residential building, provoking the processes of destruction of the foundation;

protection of the foundation from the possible formation of mold, fungus, insects.

Video description

In the video, an example of how to veneer the basement of a house inexpensively and beautifully on a pile foundation:

Rough plinth protection

In order for the base to fully perform its functions for a long time, it must be protected from wind loads, temperature extremes, atmospheric and all-penetrating ground moisture. Before proceeding with the finishing of the basement wall, it is necessary to carry out a set of measures for the so-called rough protection of the basement. There are five main aspects of the draft protection of the basement from possible destruction and the prevention of distortions of the geometry of the building itself.

On our website you can find contacts of companies specializing in finishing materials for finishing country houses. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

Laying drainage communications along the perimeter of the basement wall

To create a drainage system for the basement, a trench is dug into which drainage pipes are laid with perforation over the entire surface. Through them, the moisture that has got inside will be diverted to drainage well. A trench with drainage pipes laid in a special way is sprinkled with sand and gravel, then filled with earth.

Video description

In the video, an example of drainage for the basement:

Applying waterproofing to the outside of the basement wall

The basement is waterproofed after the initial waterproofing of the foundation base and armored belt. Sequence of work:

the foundation superstructure is coated with hot bitumen or bituminous mastic;

several layers of roofing material are applied on top;

covered with a penetrating waterproofing composition.

Production of blind areas

The blind area is called an inclined strip filled with concrete along the perimeter of the building, coming close to the basement wall. A slight slope "away from the wall" prevents water from accumulating near the foundation superstructure during rain or when snow melts. The width of the blind area must be at least 25 cm greater than the size of the roof extension. Sequence of work:

remove the top of the soil;

lay a drainage cushion of sand and gravel;

a layer of concrete is poured over the pillow with a slope from the wall.

Blind area for the foundation Source subscribe.ru

Plastering the plinth surface

It is carried out in order to level and strengthen the surface. This reduces the likelihood of cracking, provoking subsequent possible destruction. Usually, in preparation for plastering, a metal mesh is pre-packed and then plaster is applied. To impart water-repellent properties to the solution, a plasticizer is added to it.

Installation of ebbs

These structural elements act as a protective visor for the foundation wall. The ebbs can be ceramic, steel or aluminum, plastic or brick.

Upon completion of the complex of protective measures, they proceed to the main finishing of the basement.

Plinth finishing methods

Among the methods of finishing the basement wall, practiced in private housing construction, the most popular are the following technologies:

application decorative plaster, creation of relief compositions imitating granite, marble or natural stones;

the use of decorative siding panels;

finishing with profiled sheet and corrugated board;

resin tiling;

facing with natural or artificial stones, facing bricks, clinker tiles;

sheathing with thermal panels;

finishing with slate and cement particle boards.

Photo of finishing the basement of the house - imitation of stone when finishing the basement Source domsireni.ru

Finishing with decorative plaster

Finishing the plinth or facing the foundation cheaply without loss of operational and aesthetic qualities can be done by decorative plastering. The main advantages of this technique are:

sufficiently high vapor permeability;

resistance to temperature changes;

ease of application to the plastered surface;

a wide variety color palette;

good maintainability for repair and restoration work;

affordable price.

Additional Information. Experts believe that when comparing the entire range of indicators in terms of cost, quality, durability, maintainability and practicality of the coating, finishing the plinth with plaster turns out to be the most advantageous option.

Among the shortcomings, users note:

small operational resource;

the need for constant updating of the paint coating;

difficulties in washing the surface from contamination.

Modern trends in the artistic and decorative design of the facades of residential buildings did not leave without attention the plaster finish of the plinths.

Decorative plaster can give the surface any shape Source dom-steny.ru

In private homes, the most popular types of plaster are now used, creating exclusive compositions:

texture compositions used to create paintings, drawings, color mosaics;

glazing compositions that help in creating interesting effects;

relief decoration "under the stone".

siding finish

When finishing the basement of a private house in Moscow with its climate and colder regions, siding panels are often used - the term “basement siding” has even entered into construction practice. At its core, siding is a universal way to finish any surface of a house, however, basement sheathing panels are somewhat different from classic wall counterparts.

If wall siding is represented by panels with a thickness of 0.7-1.2 mm and a length of almost 4 meters, then reinforced panels are produced for the basement with a thickness of 2.5 to 3.0 mm (almost 3 times thicker than wall cladding!) And a length of 1 0-1.13 m with a width of up to 47 cm. This ensures increased resistance to mechanical damage, including accidental impacts, and rigidity with respect to temperature deformations.

Standard brick siding panel Source sargorstroy.ru

In the Russian market of facing materials, basement siding is represented by plastic and metal panels that imitate natural stones, wood, and brick in texture. Plastic panels for the plinth are made of PVC and polypropylene resins, modified with special components to improve strength, resistance to fire and sedimentary moisture. Metal - steel and aluminum.

The main advantages of basement siding include:

increased strength and rigidity of each panel individually and of the assembled structure as a whole;

resistance to the negative effects of biological factors - fungus, mold, insects;

excellent moisture resistance;

increased mechanical strength in relation to impacts and chipping;

wear resistance to abrasive action of dust and debris particles;

small deformations due to temperature differences, building settlement or soil swelling;

wide temperature range of application - the panels do not lose their properties both in severe frost (up to minus 50 degrees C) and in heat exceeding + 50 degrees. C);

resistance to solar ultraviolet - the material does not quickly age, and the color does not fade;

excellent maintainability - if necessary, the panels are easily replaced;

ease of care - the panels are easily washed from dirt.

A significant disadvantage of basement siding is the need to equip a special frame, which significantly increases the cost. finishing material and the complexity of finishing work.

Siding panels cannot be installed without crates Source podvaldoma.ru

Installing basement siding panels also has its pros and cons. The advantages of the panel installation process include the following aspects:

panels are installed on any type of plinth;

no pre-alignment required wall surface;

high culture and cleanliness of installation and installation works;

the fastening of the panels with the frame battens by means of self-tapping screws and with each other with spikes and clamps ensures a rigid fixation of the siding on the plinth.

Installation problems for plinth panels include:

the need to properly position the frame under the panels;

painstaking installation, the likelihood of marriage when connecting panels, which may subsequently affect the appearance of the base and its performance;

the need to use a special tool for cutting and fitting panels.

Finishing with profiled sheet and corrugated board

Facing the plinth with a profiled steel sheet is to some extent an analogue of the siding technology, only the plinth panels are replaced with a profiled sheet or corrugated board with a corresponding refinement of the frame. Except protective function, finishing can also be done for decorative purposes.

Video description

In the video, an example of finishing the basement of an old house:

The wave profile of the corrugated sheet is made more rigid than that of the corrugated board. According to their purpose, profiled sheets are used as roofing material, however, C13 corrugated board, having a wave height of 13 mm, is allowed for facing the plinths of private residential buildings. The thickness of the corrugated board is 0.6-0.7 mm, which is quite enough to create a solid sheathing of the foundation superstructure. The professional flooring is delivered with a galvanized or polymeric covering.

The advantages of a profiled sheet include:

high strength qualities;

external attractiveness, the possibility of implementing various types of design compositions;

resistance to corrosion and discoloration from environmental influences;

ease of installation, minimal laboriousness for installation on a plinth;

price availability.

It is important! Facing the basement with corrugated board refers to budget options for finishing foundation and basement walls and clearly outperforms other technologies in terms of price / quality.

Among the shortcomings, two factors can be noted:

the monotony of the corrugated pattern, which is perceived by some users as an indicator of an unpresentable interior;

the need to take into account geometry overall design buildings, since the wave bends of the sheets may not at all correspond to the artistic style of the building (“do not fit” into the design).

The question of combining the drawings of the wall and the basement is one of the main ones when finishing the basement of a private house with a profiled sheet Source sevparitet.ru

Resin tiles

The plinth tiles produced with resin binders are only 3-5 mm thick. Tiles are easily bent at any angle, they can even be rolled up, so this facing material is commonly called flexible stone. The length of the tile varies from 24 to 36 cm with a width of 5 to 7 cm. Resin-based tiles are produced with a smooth and embossed surface that imitates the entire range of natural facing materials in color and texture - stone, wood, facing brick.

Facing from "flexible stone" Source moypodval.ru

Due to their high flexibility, resin-based tiles can be easily laid on plinths of any configuration, including arcuate geometries. Features of the installation of such tiles are as follows:

when laying, the tiles are glued with special glue to the previously leveled and primed surface of the basement wall;

tiles can be laid directly on concrete surfaces and on the top layer of thermal insulation;

tiles are easily cut with a knife and large scissors;

the time of complete drying of the glue is 2-3 days.

Finishing with stone, brick, clinker tiles

Finishing the basement "under the stone" or "under the brick" gives the residential building solidity and monumentality. It is not at all necessary for home owners to spend money on granite, marble, rubble stone or brick. The decorative functions of finishing from natural stone materials are successfully performed by various types of facing tiles with a texture that imitates natural stones or bricks.

Natural stone tiles

It is a complete decorative alternative to classic stone foundation masonry. With back side the tile is smooth, and on the front side the stone is not processed, retaining its natural originality.

Facing with natural stone - great option for finishing the foundation wooden house Source mypodval.ru

Facing tiles "under the stone", imitating natural stones, is produced on a cement-sand basis with the addition of paint, plasticizers and protective compounds. Artificial stones have high strength characteristics, do not absorb water, easy to clean with a water jet. Artificial stone is more ductile than natural stone, so it can better withstand accidental impacts and sudden temperature changes.

Facing "under the stone" Source piatachok.ru

Clinker

Clinker tiles are a variant of facing bricks made by annealing a special refractory clay. Sintered clay is very hard and its glossy surface is highly hydrophobic. After laying, clinker tiles create an imitation of brickwork.

It is important! Clinker tiles are highly chemically inert to negative environmental influences and surpass natural and artificial stones in their durability.

Facing the basement with clinker - as an option, how to finish the foundation of the house from the outside Source tr.decorexpro.com

Facing brick is a natural ceramic product that fully imitates brickwork. It has high heat-insulating and strength qualities, which are so necessary to protect the basement and the entire facade.

Basement trimmed with facing bricks Source domsireni.ru

Finishing basement thermal panels

Socle thermal panels are facing tiles equipped with inside insulation. The facing decorative material of thermal panels is clinker tiles imitating natural stones, brick, shell rock, ceramic granite tiles or ordinary ceramic tile with imitation "under the brick". Polyurethane foam or extruded polystyrene foam is used as a heater. The thickness of the insulation layer is 20-80 mm.

Note! Practice has shown that the use of thermal panels with foamed polystyrene for lining the basement wall is unacceptable. This option of insulation is short-lived and is characterized by weak heat-shielding properties.

Thermal panels are exterior decoration and insulation Source blogremonta.com

Finishing with slate and cement particle board

Finishing the basement base with flat slate is a good idea. budget option exterior finish Houses. For the manufacture of flat slate asbestos fiber, Portland cement and water are used. The lining of the basement wall is recommended to be made of pressed slate, which is much denser and stronger than its unpressed counterpart. The main advantages of slate materials include:

resistance to aggression of sedimentary moisture;

low coefficient of water absorption;

resistance to low temperatures and sudden temperature changes;

resistance to open flame, slate sheets do not burn;

slate can be painted using acrylic primer and acrylic or silicone paint;

long service life within 25-30 years.

Of the shortcomings, the following factors are necessarily mentioned:

increased fragility - slate is able to collapse from the effects of a dynamic nature, for example, from being hit by a stone;

asbestos dust generated when cutting sheets during installation is extremely harmful to humans. Sheets are processed only in respirators.

Budget options for finishing the basement Source domsireni.ru

Cement-bonded particle boards (DSP) are made by pressing wood shavings with cement. CBPB is based on chips of a large fraction, the upper layer is formed from chips of a finer fraction. On the building materials market, DSP is offered with a sheet thickness of 8-36 mm. For finishing the basement wall, sheets with a thickness of 16 to 20 mm are used.

The advantages of the DSP are as follows:

good moisture resistance;

resistance to low ambient temperatures;

high degree of fire safety of DSP sheathing;

resistance to decay;

ease of machining.

There are two disadvantages:

the large weight of each element of the skin;

service life does not exceed 15 years.

Finishing the basement in a wooden house

When finishing the foundation of a wooden house and lining the basement, Special attention is given to the careful implementation of waterproofing and thermal insulation of the entire basement belt around the building. The wood from which the walls of the dwelling are built is susceptible to the processes of decay and mold reproduction, and is vulnerable to excess sediment and ground moisture. Only reliable protection of the base will prevent the penetration of liquid into the wall part and prevent it from freezing in the cold season. After taking measures for waterproofing and thermal protection of the basement, it can be finished using the technologies described above.

Finishing the basement of a wooden house Source remlandia.ru

Conclusion

The resource of long-term trouble-free operation of a residential building depends on the strength and reliability of the basement belt around the building. When the basement is destroyed, a destructive reaction of the building begins, leading to deterioration appearance building and reducing its strength properties, up to local destruction of walls and foundations. Any way to finish the basement to a certain extent protects and ennobles the facade of the building. Developers are only required to achieve an optimal match between price, quality and decorative properties finishing material so that the basement cladding does not stand out from the overall picture of the appearance of the building.